A pulse combustion rotary hearth furnace

A technology of pulsed combustion and rotary hearth furnace, which is used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of reducing the utilization efficiency of pellet furnaces, insufficient heating quality, and low pellet heating efficiency. The effect of small fluctuation, improved quality and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

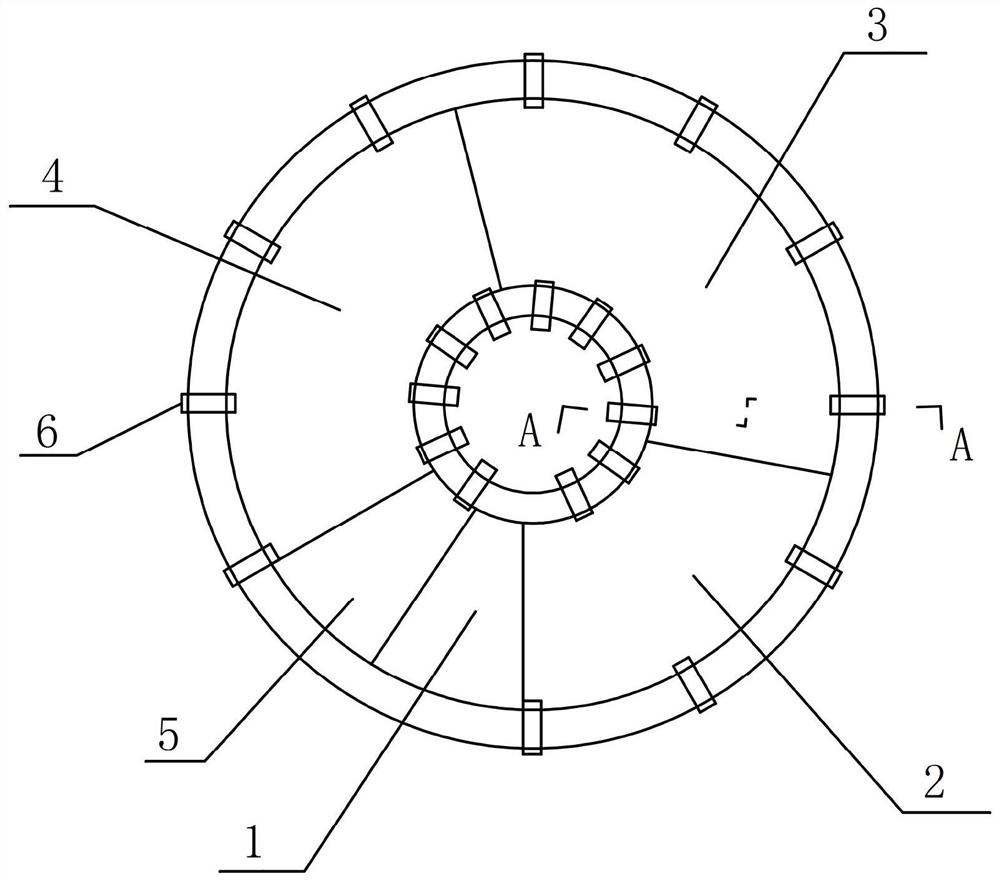

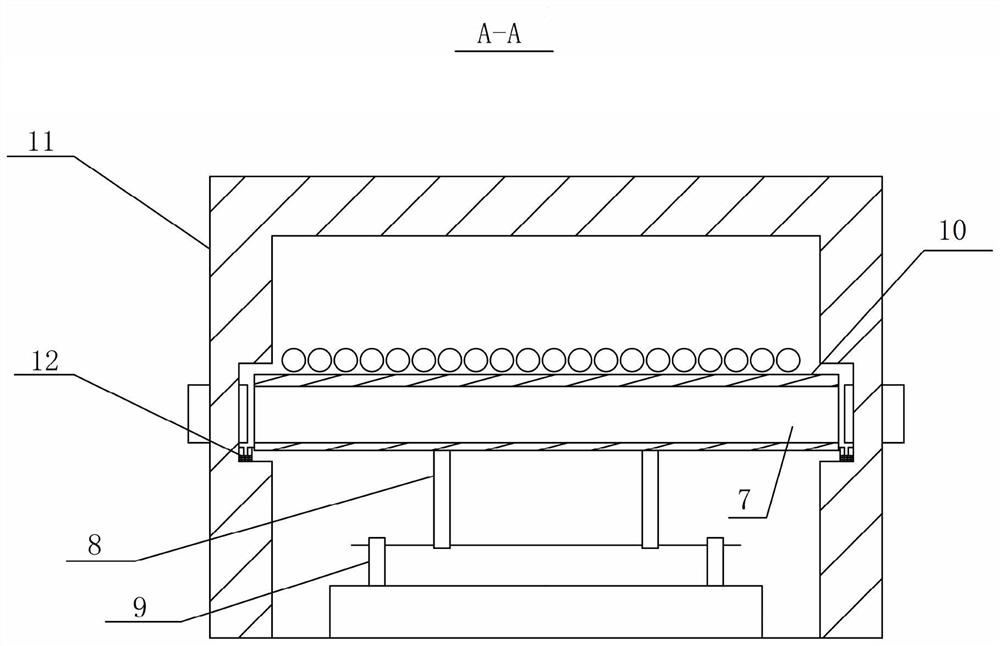

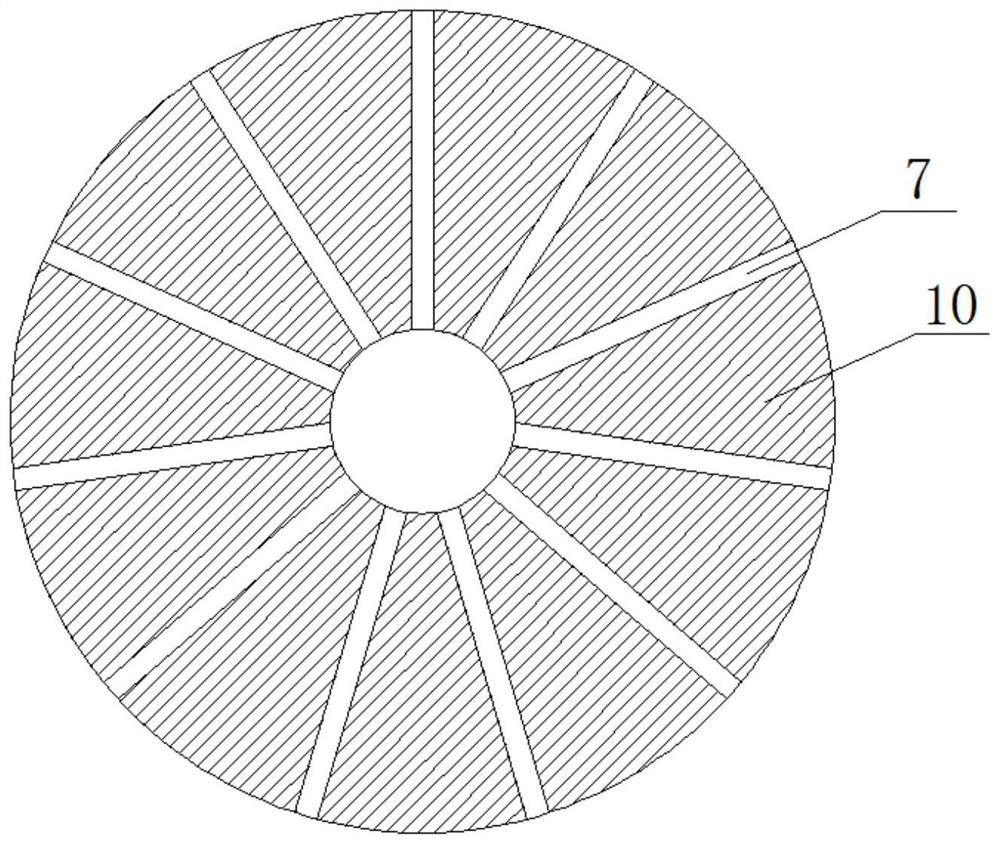

[0021] like Figure 1 to Figure 3 As shown, a pulse-type combustion rotary hearth furnace includes a furnace body 11, a furnace top and a furnace bottom 10. The space surrounded by the furnace body 11, the furnace roof and the furnace bottom 10 forms a furnace, and the radial section of the furnace is annular , the annular furnace is divided into a feeding zone 1, a preheating zone 2, a medium temperature zone 3, a high temperature zone 4 and a discharge zone 5 according to the direction of material rotation. An annular groove is opened in the middle of the inner side wall of the furnace body 11, and the furnace body 11 is along the A material inlet, a material outlet and eleven burners 6 are arranged circumferentially, and the material inlet, material outlet and eleven burners 6 are located on the side wall of the furnace body 11 at the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com