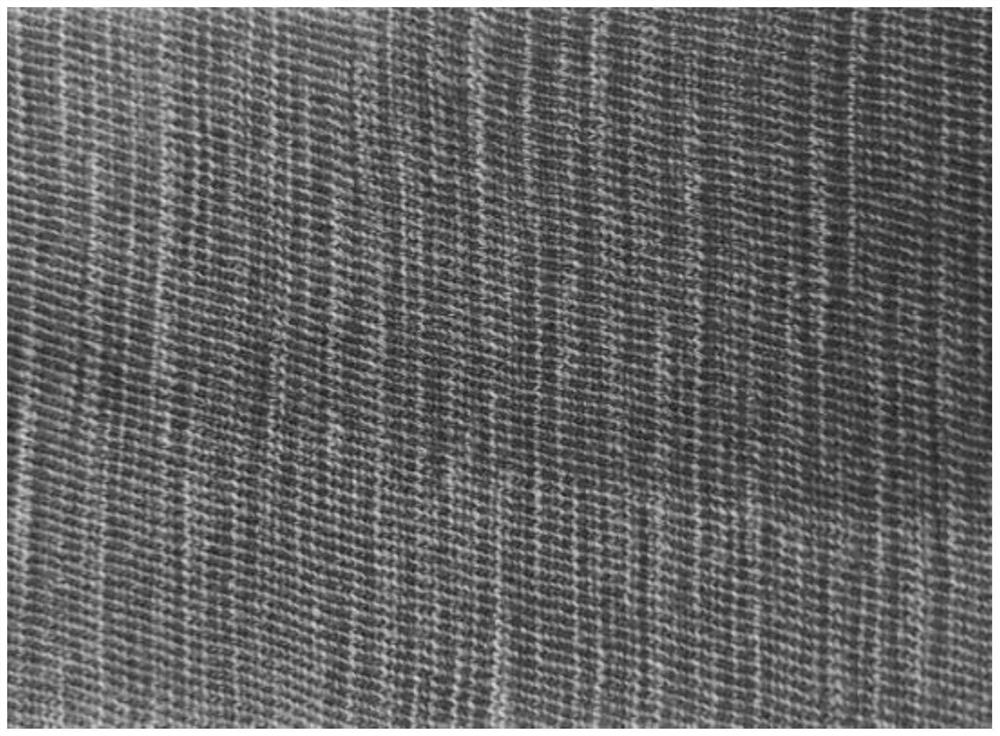

Pure cotton knitted fabric with alternating shades of color texture and distressed style and its manufacturing method

A technology of knitted fabrics and pure cotton, which is applied in the field of textile printing and dyeing, can solve the problems of difficult quality control, complicated process, and failure to meet market requirements, and achieve the effect of unique fabric pattern and hand feeling, simple processing process, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for processing a 30s×2SK JERSEY pure cotton knitted fabric with alternating shades of texture and an old-fashioned style. The method includes the following steps:

[0052] Select two kinds of 30s / 1 pure cotton combed yarns with different twists, one yarn twist is 800 twists / m, and the other yarn twist is 1200 twists / m. On the circular knitting machine, the above two kinds of yarns are fed into the yarn guide port of the loom at the same time, and 30s×2SK JERSEY pure cotton gray fabrics with different twist yarns are woven.

[0053] The pure cotton gray cloth with yarns of different twists is scoured, bleached, and shaped, and the obtained fabric is made into a garment.

[0054] Carboxypolyethylene glycol, an anion treatment agent, is used to anionize the finished garment. The dosage of carboxypolyethylene glycol is 0.3g / L, and the liquor ratio is controlled at 1:20; the temperature of anionization treatment is 60°C, and the treatment time...

Embodiment 2

[0060] This embodiment provides a method for processing a 30s / 1SK JERSEY pure cotton knitted fabric with alternating shades of texture and distressed style. The method includes the following steps:

[0061] Select two kinds of 30s / 1 pure cotton combed yarns with different twists, one yarn twist is 800 twists / m, and the other yarn twist is 1200 twists / m. On the circular knitting machine, two modes of high-twisted yarn and two modes of low-twisted yarn are used to alternately feed the above two types of yarn into the loom to weave 30s×1SK JERSEY pure cotton gray fabric with specific yarns of different twists.

[0062] Scouring and bleaching pure cotton fabrics with yarns of different twists.

[0063] Then use a cationic treatment agent for cationic treatment, the treatment process is that the amount of polyamide resin aqueous solution is 3% owf, the bath ratio is controlled as 1:10; the temperature of cationic treatment is 60 °C; the treatment time is 20min; the cationic modific...

Embodiment 3

[0068] This embodiment provides a method for processing 20s / 1SKPique pure cotton knitted fabrics with alternating shades of texture and distressed style. The method includes the following steps:

[0069] Select two kinds of 20s / 1 pure cotton combed yarns with different twists, one yarn twist is 600 twists / m, and the other yarn twist is 1000 twists / m. On the circular knitting machine, two modes of high-twisted yarn and two modes of low-twisted yarn are used to alternately feed the above two types of yarn into the loom to weave 20s×1SKPique pure cotton gray fabric with specific yarns of different twists.

[0070] The pure cotton gray cloth with yarns of different twists is scoured, bleached, and shaped, and the obtained fabric is made into a garment.

[0071] Use the anion treatment agent carboxypolyethylene glycol to anionize the finished garment. The dosage of carboxypolyethylene glycol is 0.5g / L, and the liquor ratio is controlled at 1:15; the temperature of anionization trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com