Spliced floor combination

A splicing, splicing board technology, applied in the direction of floor, covering/lining, building, etc., can solve the problems of single splicing form of rectangular floor strips, simple splicing pattern, splicing combination, and limited patterns, etc., to achieve convenient splicing. Stability, good splicing stability and high assembling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

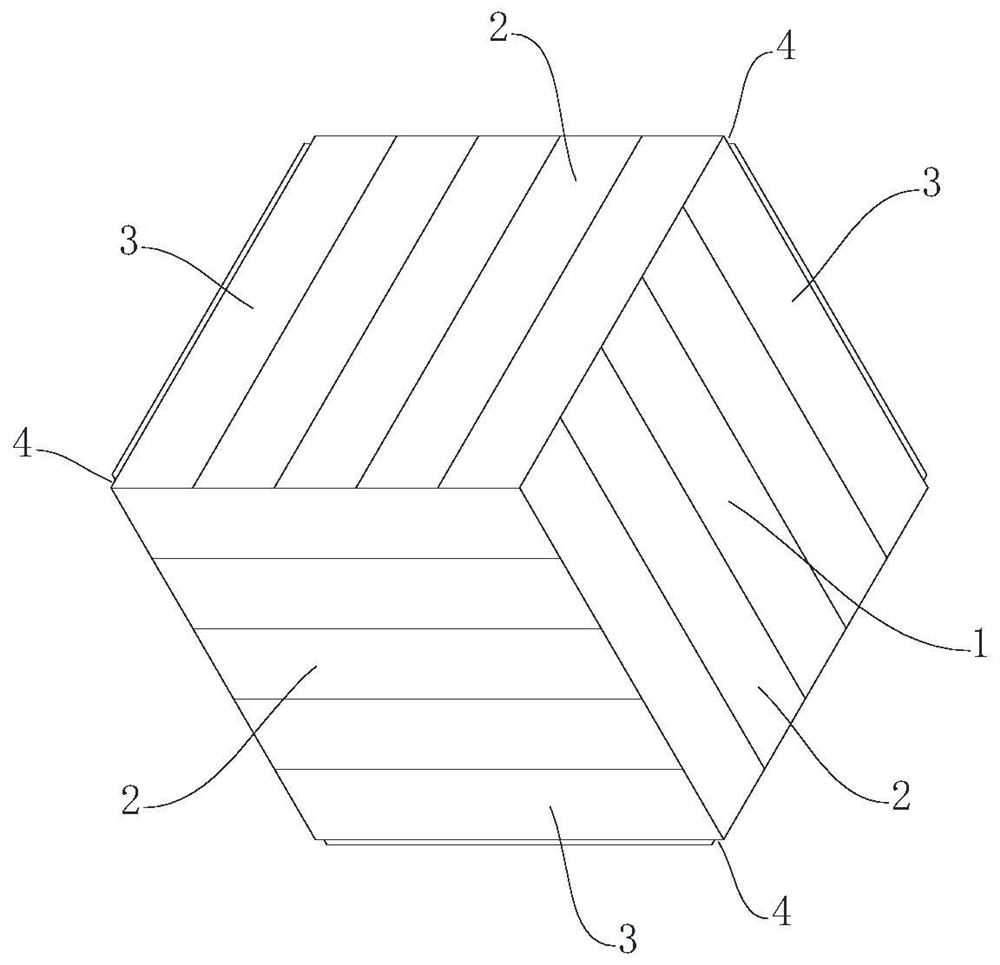

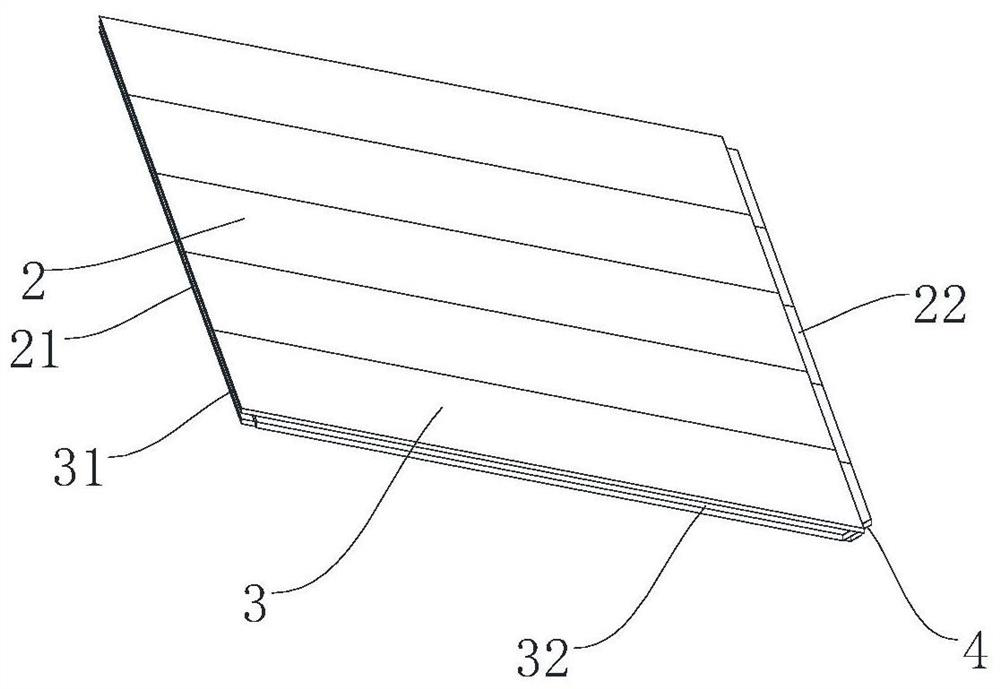

[0032] Such as Figure 1-6 As shown, the spliced floor combination includes three diamond-shaped splicing panels 1 with the same structure that are spliced with each other in a hexagonal shape. B3 structure, the floor strips B3 are located at the edges of three diamond-shaped splicing panels 1, and the splicing corners of the floor strips B3 are provided with cut corners 4 . The long side of floor bar A2 is 5 times of the short side of floor bar A2, and the long side of floor bar B3 is 5 times of the short side of floor bar B3, in the present embodiment, select the long side of floor bar A2 and floor bar B3 The sides are 550mm, and the short sides of the floorboards A2 and B3 are 110mm.

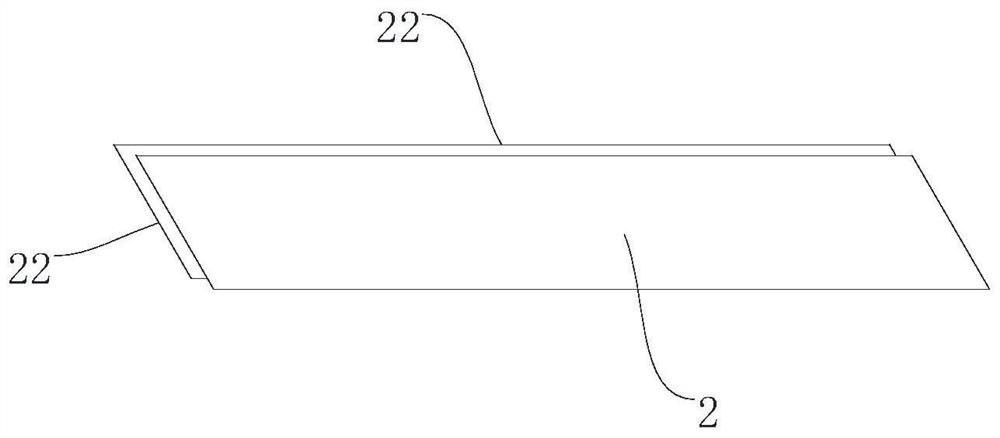

[0033] One long side and one short side of the floor strip A2 are provided with a groove A21, the other side long side and the other short side of the floor strip A2 are provided with a tenon A22, and the short side where the groove A21 is located The angle between the side and the long...

Embodiment 2

[0041] Such as Figure 7-12 As shown, the spliced floor combination includes three diamond-shaped splicing panels 1 with the same structure that are spliced with each other in a hexagonal shape. B3 structure, the floor strips B3 are located at the edges of three diamond-shaped splicing panels 1, and the splicing corners of the floor strips B3 are provided with cut corners 4 . The long side of floor bar A2 is 5 times of the short side of floor bar A2, and the long side of floor bar B3 is 5 times of the short side of floor bar B3, in the present embodiment, select the long side of floor bar A2 and floor bar B3 The sides are 550mm, and the short sides of the floorboards A2 and B3 are 110mm.

[0042] One long side and one short side of the floor strip A2 are provided with a groove A21, the other side long side and the other short side of the floor strip A2 are provided with a tenon A22, and the short side where the groove A21 is located The angle between the side and the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com