A kind of modification method of copper-based conductive contact

A conductive contact, copper-based technology, applied in metal material coating process, coating, heating inorganic powder plating, etc., can solve the problems of poor oxidation resistance, arc erosion resistance, large contact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

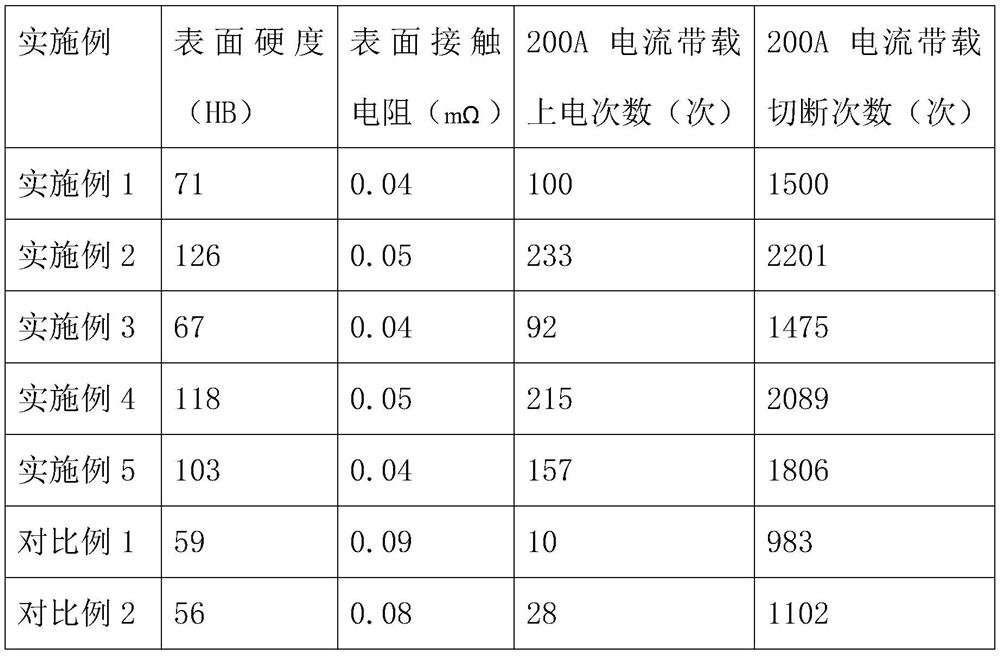

Examples

Embodiment 1

[0025]Embodiment 1: a kind of copper-based conductive contact modification method comprises the following steps: adding graphene powder and hydrophilic surfactant into water to form a mixture, based on the total mass of the mixture, the mass percentage of graphene powder is 0.1%, the mass percentage of hydrophilic surfactant is 0.2%, the purity of graphene powder is ≥99.5%, the particle size of graphene powder is 0.5-5 μm, and the hydrophilic surfactant is polyvinylpyrrolidone, poly The molecular weight of vinylpyrrolidone is 35,000; the mixture is heated in a water bath, and ultrasonic vibration is performed in an ultrasonic oscillator while the water bath is heating to realize the first physical dispersion. 18kHz; after the first physical dispersion, keep the water bath heating state and carry out magnetic stirring in the magnetic stirrer to realize the second physical dispersion. The water bath heating temperature for the second physical dispersion is 65°C, and the magnetic ...

Embodiment 2

[0026] Embodiment 2: a kind of method for modifying copper-based conductive contacts, comprising the following steps: adding graphene powder and hydrophilic surfactant to water to form a mixture, based on the total mass of the mixture, the mass percentage of graphene powder is 0.1%, the mass percentage of hydrophilic surfactant is 2%, the purity of graphene powder is ≥99.5%, the particle size of graphene powder is 0.5-5 μm, and the hydrophilic surfactant is polyvinylpyrrolidone, poly The molecular weight of vinylpyrrolidone is 45,000; the mixture is heated in a water bath, and ultrasonic oscillation is performed in an ultrasonic oscillator while the water bath is heating to realize the first physical dispersion. The water bath heating temperature for the first physical dispersion is 65°C, and the ultrasonic oscillation frequency After the first physical dispersion, keep the water bath heating state and carry out magnetic stirring in the magnetic stirrer to realize the second ph...

Embodiment 3

[0027] Embodiment 3: the mass percent composition of graphene powder is 0.2%, the mass percent composition of hydrophilic surfactant is 0.4%, the thickness that graphene slurry is coated on the electric contact surface of copper-based conductive contact 10 μm, other steps are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com