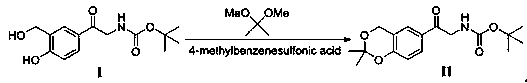

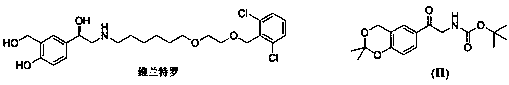

Preparation method for synthesizing vilanterol intermediate by catalysis with modified graphene

An intermediate and graphene technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical recovery, etc., can solve the problems of p-toluenesulfonic acid that is difficult to recycle, deep product color, poor color, etc., and achieve graphite The catalyzed synthetic route of ene is environmentally friendly, solves the problem of difficult recycling, and reduces the pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

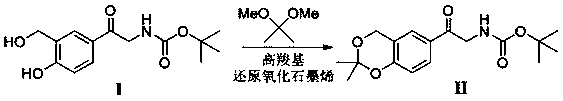

Method used

Image

Examples

Embodiment 1

[0018] (1) Take a 3000mL glass beaker, measure 500 grams of 15% oleum, add it, and cool down to -3~2 in an ice-salt bath o C, under stirring, add 6.25 grams of graphite powder into the fuming sulfuric acid, after stirring and dispersing, continue to stir, slowly add 32 grams of potassium permanganate to the fuming sulfuric acid solution of graphite powder in batches, keep warm for -3~2 o C continued to stir for 2.5 hours, after the stirring ended, the reaction solution was warmed up to 45 oC , add 51.4 grams of deionized water to the reaction solution, and the reaction solution is warmed up to 100 oC , continue to stir and react for 4 hours;

[0019] (2) Naturally cool to 20 after stopping heating oC , under stirring, add 360 grams of hydrogen peroxide in batches to the reaction system, add 62 grams of 2mol / L hydrochloric acid after stirring for 1 hour, divide it into three times, each time use 1400mL deionized water, and wash the dialysis bag 5 times.

[0020] (3) Transfer t...

Embodiment 2

[0022] (1) Take a 5000mL glass beaker, measure 1000 grams of 30% fuming sulfuric acid, add it, and cool down to 0~2 in an ice-salt bath o C, add 20 grams of graphite powder into the fuming sulfuric acid solution under stirring, after stirring and dispersing, continue stirring, slowly add 40 grams of potassium permanganate in the fuming sulfuric acid solution of graphite powder in batches, keep warm for 0~2 o C continued to stir for 3 hours, after the stirring ended, the reaction solution was warmed up to 55 oC , add 200 grams of deionized water to the reaction solution, and raise the temperature of the reaction solution to 100 oC , continue to stir and react for 5 hours;

[0023] (2) Naturally cool to 20 after stopping heating oC , under stirring, add 1000 grams of hydrogen peroxide in batches to the reaction system, after stirring for 1 hour, add 62 grams of 2mol / L hydrochloric acid, and divide it several times, each time with 2000mL deionized water, and use a dialysis bag ...

Embodiment 3

[0031] Weigh 2.81g of vilanterol intermediate (I) tert-butyl (2 - (4 - hydroxy - 3-(hydroxymethyl) phenyl) - 2 - oxoethyl) carbamate and add 2.08g of 2,2-dimethoxypropane to In a 100 mL single-necked flask, add 60 mL of chlorobenzene, add magnets of appropriate size, stir and disperse, then add 4 mg of modified and synthesized edge highly carboxylated reduced graphene oxide, then heat the oil bath and keep it warm for 100 o C was reacted for 6 hours, and the reaction was detected. Add 30 mL of saturated sodium bicarbonate, stir and wash for 30 minutes, extract, collect the organic phase, filter the organic phase after drying with anhydrous sodium sulfate, collect the liquid phase, and concentrate by rotary evaporation. Add isopropyl ether into another 50mL single-necked flask, put in a suitable magnet, place it in a low-temperature reactor, and keep warm for 0~3 o C. Add the concentrated slurry dropwise to isopropyl ether under stirring. After the dropwise addition, keep warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com