Device and method for removing solid particles in ultrahigh pure ethyl silicate steel cylinders

A technology of ethyl silicate and solid particles, which is applied in the direction of separation methods, dispersed particle filtration, cleaning methods and appliances, and can solve the problems of tail gas emission and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

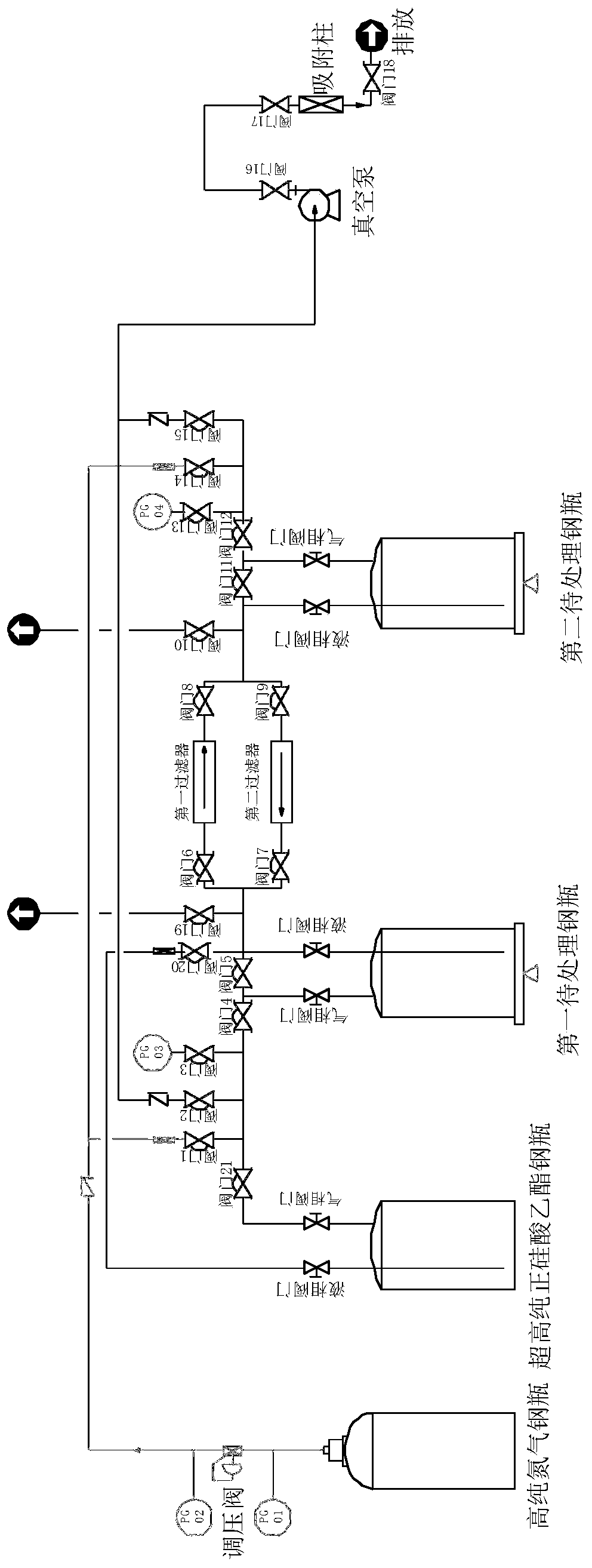

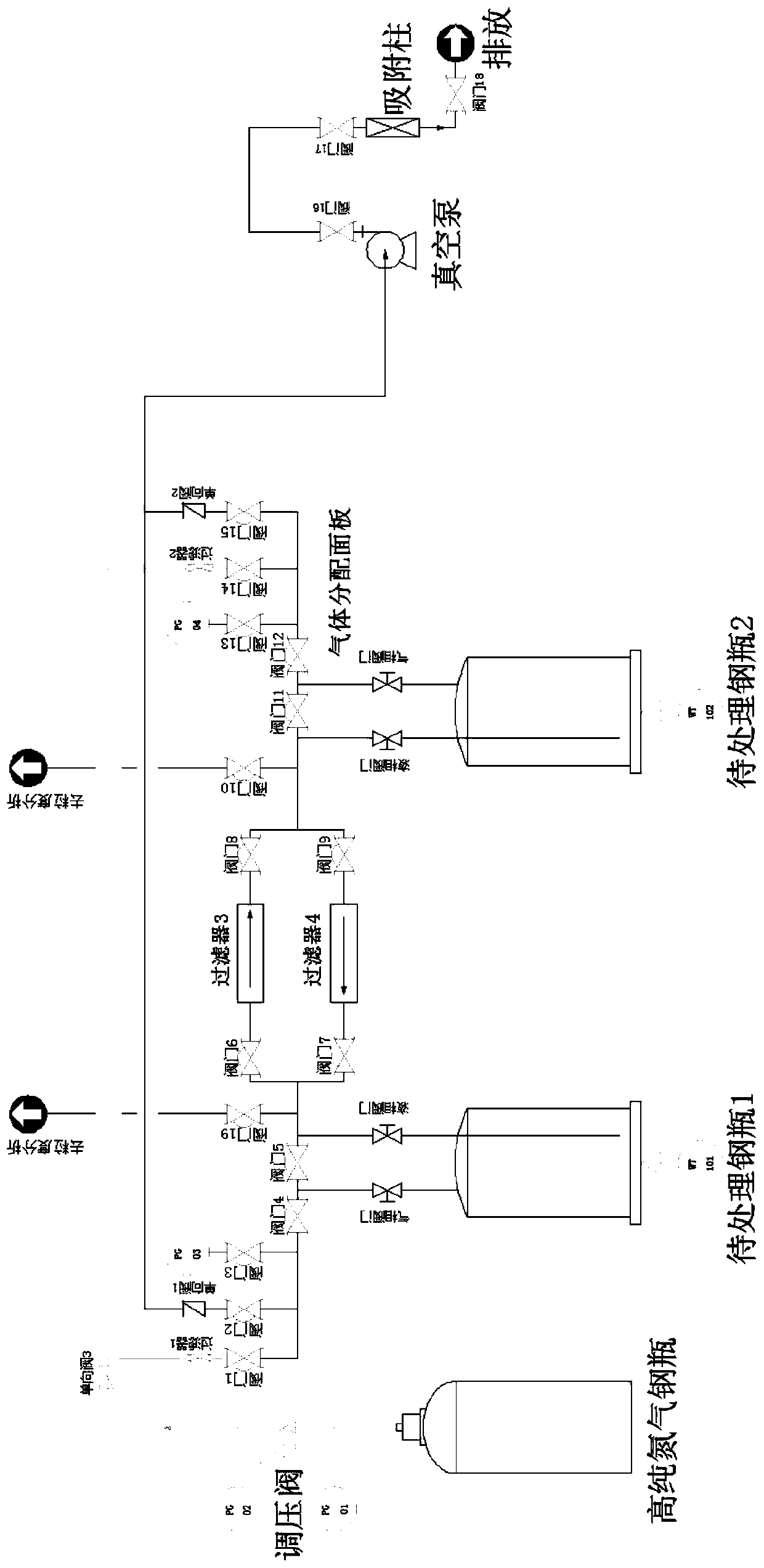

[0064] use figure 2 The device shown is mainly composed of filters, high-purity nitrogen cylinders, qualified product cylinders, untreated cylinders, cylinder scales, vacuum pumps, tail gas adsorption columns, gas distribution panels and corresponding connecting pipelines, valves and instruments.

[0065] The process consists of qualified product washing and filtering, vacuuming, and tail gas adsorption units. Charge a certain amount of qualified tetraethyl orthosilicate into the steel cylinder 1 to be treated in advance. In the first step, the pressure of high-purity nitrogen is adjusted to 15-20 psig through the pressure regulating valve of the steel cylinder; Valve, after flushing high-purity nitrogen gas into cylinder 2 to be processed to a pressure of 1 to 5 psig, close the valve liquid phase valve and valve 14 of cylinder 2 to be processed; the third step is to open the gas phase valve and valve 15 of cylinder 2 to be processed, and The gas in the steel cylinder 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com