A transient temperature prediction method for permanent magnet synchronous motors used in aviation

A permanent magnet synchronization and prediction method technology, applied in the direction of motor generator testing, thermometers, thermometer parts, etc., can solve the problem of short working time, accurate reflection of temperature distribution, motor prone to start, brake or large overload And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

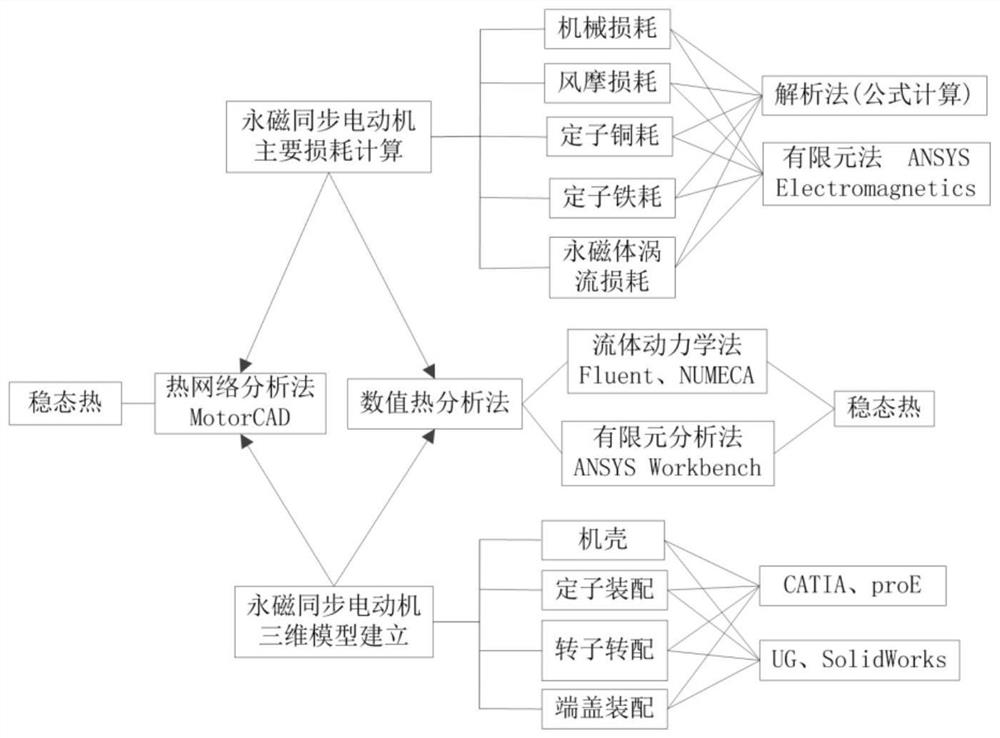

Method used

Image

Examples

Embodiment Construction

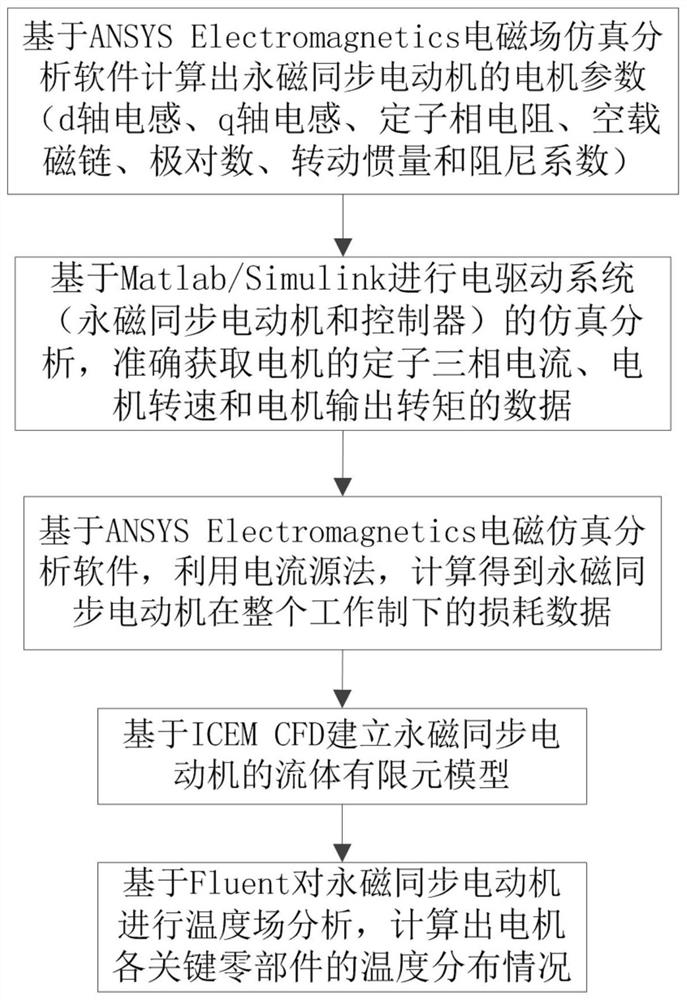

[0044] The method for predicting the transient operating temperature of the aviation permanent magnet synchronous motor proposed by the present invention is mainly based on electromagnetic simulation software, Matlab / Simulink electric drive system simulation analysis model, ICEM CFD, Fluent and CFD-Post fluid simulation software to complete the motor transient temperature The specific steps of the co-simulation of the field are as follows:

[0045] Step 1: Build a two-dimensional electromagnetic field model of the permanent magnet synchronous motor in the electromagnetic simulation software, use the external circuit method or the voltage source method for electromagnetic analysis, and calculate the d-axis inductance, q-axis inductance, stator phase resistance, and no-load magnetic field of the motor. The seven parameters are chain, number of pole pairs, moment of inertia and damping coefficient.

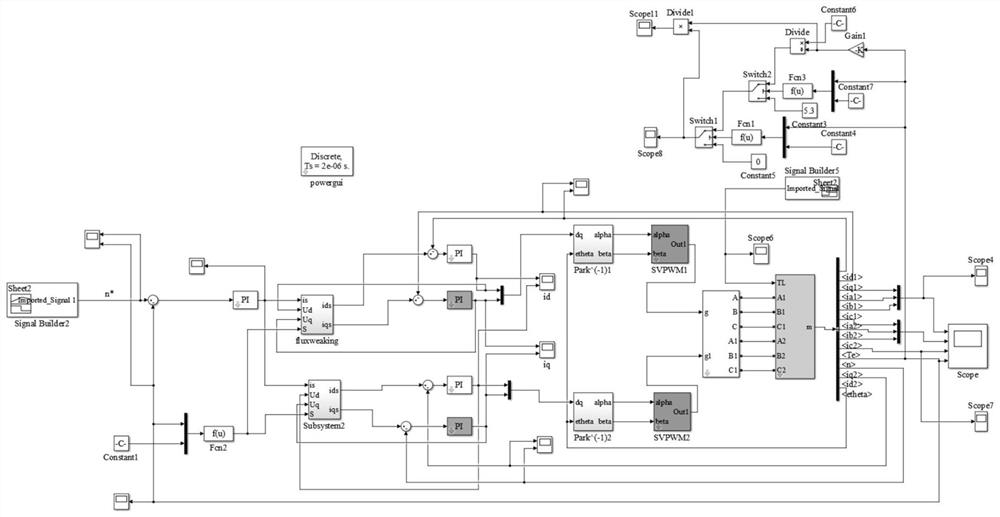

[0046] Step 2: Build the simulation model of the electric drive system (includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com