Polar pesticide determination using chromatography

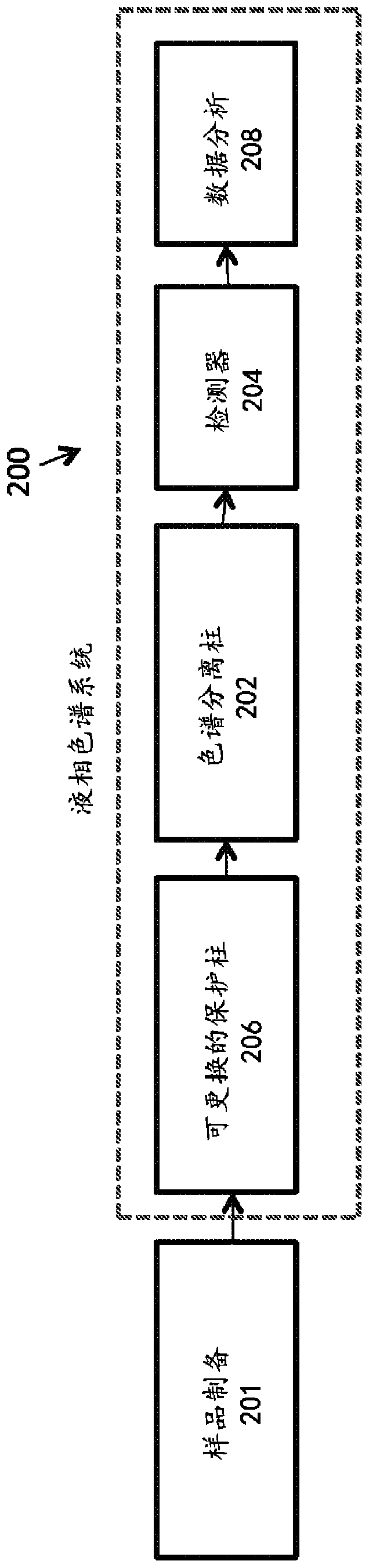

A chromatographic method and pesticide technology, applied in the field of anionic polar pesticides and polar pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

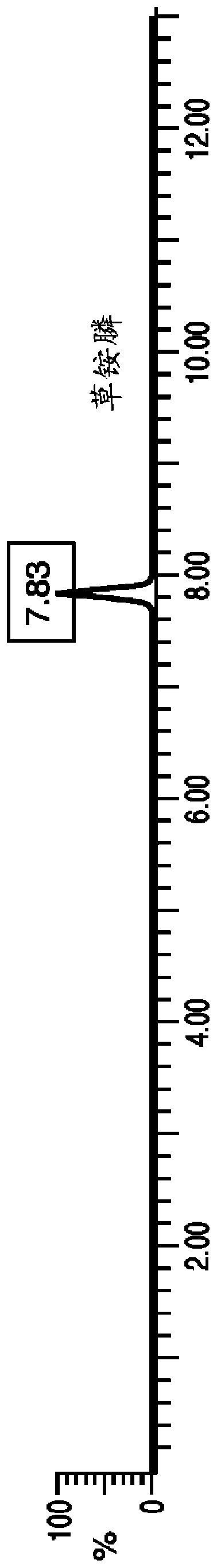

[0087] The methods of the present disclosure were used to determine polar pesticides in orange juice. Tested for the following polar pesticides: glyphosate, AMPA, glufosinate, perchlorate, ethephon, aluminum triethronate, maleic hydrazide, phosphonic acid, and chlorate. Table 2 shows the MS conditions for each of these polar pesticides. Orange juice samples were extracted using the QuPPe extraction method. A 10 mL aliquot of the sample was acidified using 10 mL of 1% formic acid in MeOH. The mixture was shaken for 10 minutes and centrifuged at 4000 rpm for 5 minutes. The mixture was then filtered using a 0.45 micron filter. Filtered sample extracts were spiked with approximately 250 ppb of each pesticide before introduction to the chromatographic system.

[0088] Table 2: Example 1MS Conditions

[0089]

[0090]

[0091] Chromatographic systems include commercially available from Waters Corporation, Milford, MA, USA. system. Columns are commercially available f...

Embodiment 2

[0101] Initial conditions and analytical methods for the analysis of polar pesticides in extracted food matrices are described.

[0102] Column Equilibration: Before installing the column, the LC system can be acid washed to remove metal ions. When the column is initially received, the column can be flushed for 50 column volumes in 50% acetonitrile / 50% (LCMS grade water). For example, for a 3.0 mm x 150 mm column, 1 column volume equals 1.06 mL. At a flow rate of 0.45 mL / min, it takes 2.35 min to fill one column volume. Equilibration may include initial mobile phase conditions for 20 column volumes before the first injection is performed.

[0103] LC conditions can be the same as those used in Example 1. Exemplary gradients are provided in Table 5.

[0104] Table 5: Example 2 gradient conditions

[0105]

[0106]

[0107] LC conditions can be the same as those used in Example 1. Gradients can be as provided in Table 5. The sample may include various polar pestic...

Embodiment 3

[0122] Samples of onions and spinach labeled organic were purchased from retail outlets, homogenized, and extracted using the EURL polar pesticide rapid extraction method.

[0123] Table 8: Example 3, Liquid Chromatography System

[0124] LC system ACQUITY UPLC I-Class Chromatographic column Torus DEA 2.1×100mm mobile phase A 50mM ammonium formate pH 2.9 mobile phase B 0.9% formic acid in acetonitrile strong wash 10:90 acetonitrile: water weak wash 90:10 acetonitrile: water Column temperature 50℃ Sample temperature 10℃ Injection volume 10 μL flow rate 0.5mL / min operation hours 20 minutes

[0125] Table 9: Example 3 MS instrument settings

[0126]

[0127]

[0128] The mobile phase gradients used are listed in Table 10. The gradient was held at 320 μL.

[0129] Table 10: Example 3 mobile phase gradient

[0130] Time (Min) The first solvent (%) Second solvent (%) cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com