Conductive spraying powder, preparation method, preparation system and use method

A technology of spraying powder and conductive powder, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of easy agglomeration and agglomeration of powder coatings, and achieve easy promotion and preparation Simple process, good overall gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

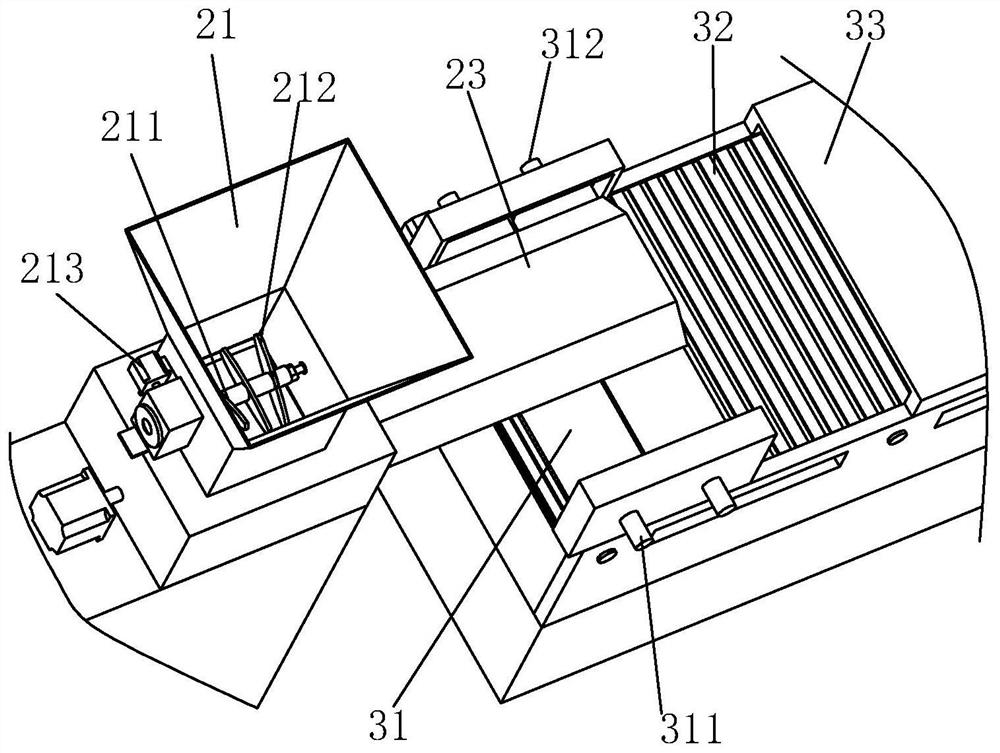

[0072] The preparation technology of conductive spraying powder comprises the following steps:

[0073] (1) Premixing, mixing the raw materials other than aluminum oxide evenly;

[0074] (2) Mixing and extruding, put the uniformly mixed raw materials into the extruder for mixing, the temperature of the melting section is 115±5°C, the temperature of the mixing section is 105±5°C, and the mixture fluid is extruded;

[0075] (3) Cooling, cooling the extruded mixture fluid to room temperature to form a solid mixture;

[0076] (4) Crushing, coarsely crushing the solid obtained in step (3) into particles with a particle size of 0.5-1 cm; then finely grinding it into powder; and sieving to obtain a powder coating with a particle size of 20-35 μm.

[0077] After fine processing and grinding into powder in step (4), aluminum oxide powder is added before sieving.

[0078] The use method of conductive spraying powder comprises the following steps:

[0079] Step 1. Evenly spray the con...

Embodiment 6

[0082] Conductive spraying powder, the difference between embodiment 6 and embodiment 4 is that 10% Al(OH) is also added in the auxiliary agent 3 ;Al(OH) 3 The purity of the powder is greater than 99.5%, the particle size is below 3000 mesh, and the particle size of the prepared powder coating is 20-35 μm.

Embodiment 7

[0084]Conductive spray powder, the difference between embodiment 7 and embodiment 4 is that the auxiliary agent contains 5% by weight of bentonite, and the rest is barium sulfate and pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com