A kind of preparation method of high hardness wear-resistant stainless steel

A stainless steel, wear-resistant technology, applied in the field of alloy steel, can solve the problems of large internal stress, film delamination, low adhesion, etc., and achieve high elastic modulus, precise and controllable conditions, and complete coating functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

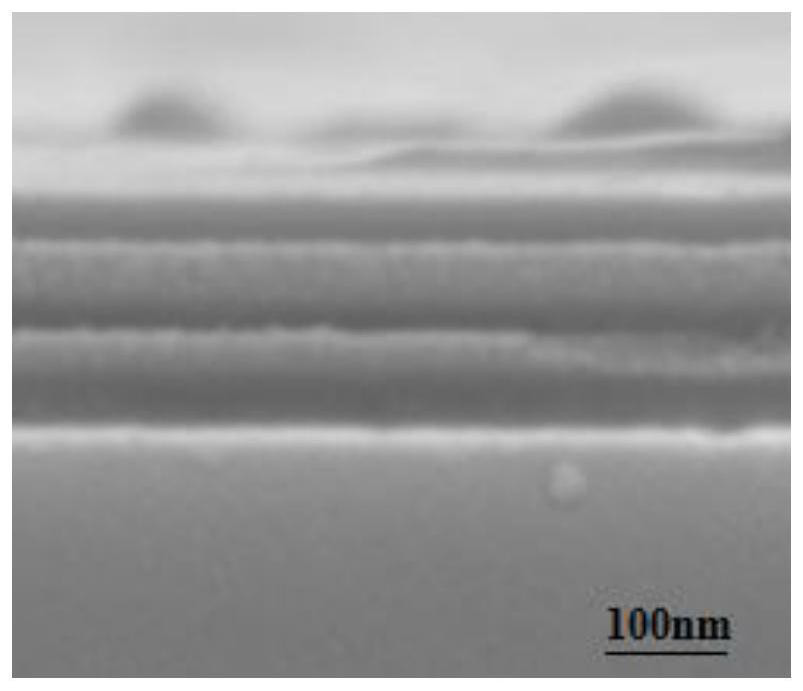

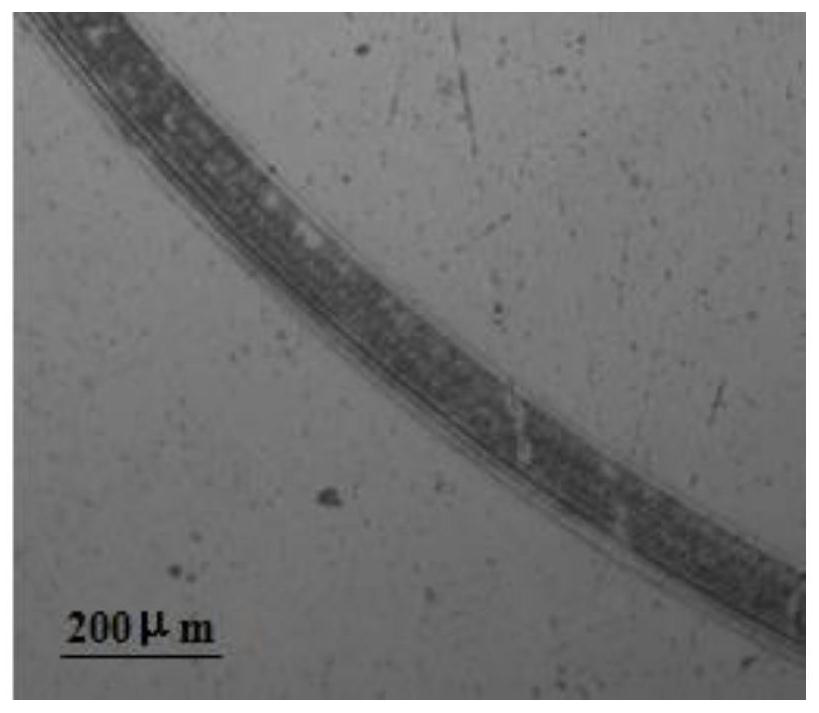

[0033] A preparation method of high-hardness and wear-resistant stainless steel, the steel grade is Cr 25 Mo 3 Ti, stainless steel with a size of 60x60mm is the base material, characterized in that:

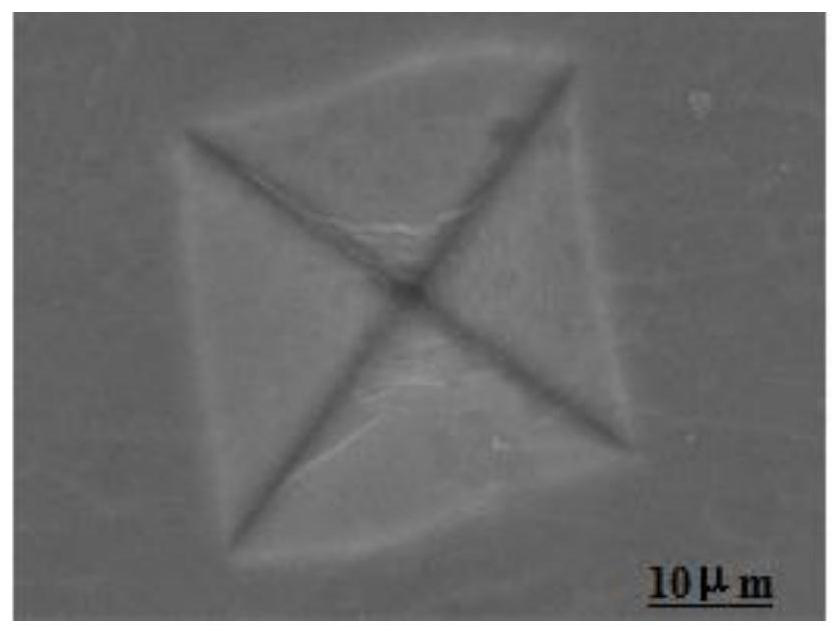

[0034] a. The steel grade is Cr 25 Mo 3 Ti, the stainless steel matrix material with a size of 60x60mm is properly machined to make it a tool or mold shape that meets industrial standards; then the matrix is subjected to high-temperature quenching at 1240°C and three times of high-temperature tempering at 560°C. Grind with 800#, 1000#, 1500# water sandpaper in turn, and use diamond with a particle size of 0.1 μm as a polishing agent to perform polishing on a polishing machine;

[0035] b. Carry out multi-step cleaning and pretreatment of tap water, alcohol and other mixed solvents, acid-alkali treatment solution, high-purity water-ultrasonic, acetone-ultrasonic and other multi-step cleaning and pretreatment on the tool or mold base, and then dry it for later use; the acid-ba...

Embodiment 2

[0040] A preparation method of high-hardness and wear-resistant stainless steel, the steel grade is Cr 17 Mo 2 Ti, stainless steel with a size of 80x80mm is the base material, characterized in that:

[0041] a. The base number is Cr 17 Mo 2 Ti and stainless steel materials with a size of 80x80mm are properly machined to make them a tool or mold shape that meets industrial standards; then the substrate is subjected to high-temperature quenching at 1240°C and three times of high-temperature tempering at 560°C, and the heat treatment is performed on a grinding machine in sequence. Grind with 800#, 1000#, 1500# water sandpaper, and use diamond with a particle size of 0.1 μm as a polishing agent to polish on a polishing machine;

[0042] b. Carry out multi-step cleaning and pretreatment of tap water, alcohol and other mixed solvents, acid-alkali treatment solution, high-purity water-ultrasonic, acetone-ultrasonic and other multi-step cleaning and pretreatment on the tool or mold...

Embodiment 3

[0047] A preparation method of high-hardness and wear-resistant stainless steel, the selected grade is 0Cr 19 Ni 9 , stainless steel with a size of 60x70mm as the base material, characterized in that:

[0048] a, the pair of grades is 0Cr 19 Ni 9 , The stainless steel base material with a size of 60x70mm is properly machined to make it a tool or mold shape that meets industrial standards; then the base is subjected to high-temperature quenching at 1240°C and three times of high-temperature tempering at 560°C. Grind with 800#, 1000#, 1500# water sandpaper, and use diamond with a particle size of 0.1 μm as a polishing agent to polish on a polishing machine;

[0049] b. Carry out multi-step cleaning and pretreatment of tap water, alcohol and other mixed solvents, acid-alkali treatment solution, high-purity water-ultrasonic, acetone-ultrasonic and other multi-step cleaning and pretreatment on the tool or mold base, and then dry it for later use; the acid-base treatment solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com