A composite high-performance polycarboxylate water reducer and its preparation method and application

A technology of water reducing agent and polycarboxylic acid, applied in the field of concrete, can solve the problems of poor pumpability, large hydration heat release, large fluidity loss, etc., to improve pumping performance, alleviate hydration concentration, and reduce discharge. The effect of heat rate peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

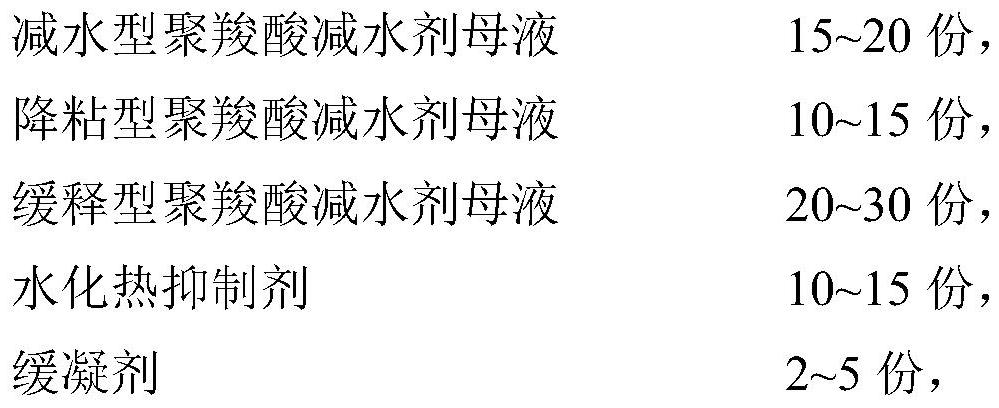

[0043] A composite high-performance polycarboxylate water reducer, prepared from the following raw materials in parts by weight:

[0044]

[0045]Among them, the water-reducing polycarboxylate superplasticizer mother liquor is prepared by the following method: 320 parts of methallyl polyoxyethylene ether are dissolved in water as substrate solution I; 40 parts of acrylic acid are dissolved in water to obtain a solution A; Dissolve 2.0 parts of mercaptopropionic acid and 0.8 parts of vitamin C in water to obtain solution B; at 25°C, add hydrogen peroxide to substrate solution I, and after stirring for 10 minutes, add solution A and solution B dropwise at the same time, drop The addition process lasts for 2 hours, after the dropwise addition is completed, keep warm for 1 to 2 hours, add alkali to adjust the pH to 6 to 7, and the product is obtained; When it is 0.2%, the water reduction rate is ≥30%;

[0046] The viscosity-reducing polycarboxylate superplasticizer mother liqu...

Embodiment 2

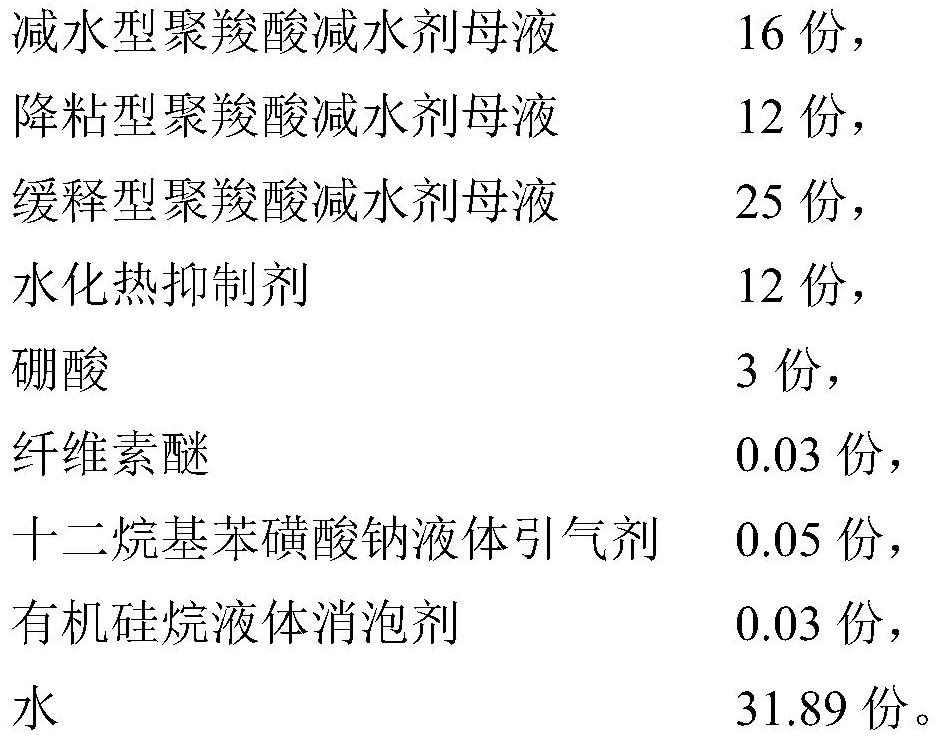

[0053] A composite high-performance polycarboxylate water reducer is prepared from the following raw materials in parts by weight:

[0054]

[0055] Among them, the preparation method of water-reducing polycarboxylate superplasticizer mother liquor, viscosity-reducing polycarboxylate superplasticizer mother liquor, slow-release polycarboxylate superplasticizer mother liquor and hydration heat inhibitor is the same as that of the corresponding raw materials in Example 1. The preparation method is the same.

[0056] The composite high-performance polycarboxylate water reducer for barite concrete is prepared by the following method:

[0057] Add water-reducing polycarboxylate superplasticizer mother liquor, viscosity-reducing polycarboxylate superplasticizer mother liquor and slow-release polycarboxylate superplasticizer mother liquor into the compound tank, stir well, and then add hydration heat inhibitor agent, sodium gluconate, guar gum, sodium rosinate liquid air-entraini...

Embodiment 3

[0060] A composite high-performance polycarboxylate water reducer is prepared from the following raw materials in parts by weight:

[0061]

[0062] Among them, the preparation method of water-reducing polycarboxylate superplasticizer mother liquor, viscosity-reducing polycarboxylate superplasticizer mother liquor, slow-release polycarboxylate superplasticizer mother liquor and hydration heat inhibitor is the same as that of the corresponding raw materials in Example 1. The preparation method is the same.

[0063] The composite high-performance polycarboxylate water reducer for barite concrete is prepared by the following method:

[0064] Add water-reducing polycarboxylate superplasticizer mother liquor, viscosity-reducing polycarboxylate superplasticizer mother liquor and slow-release polycarboxylate superplasticizer mother liquor into the compound tank, stir well, and then add hydration heat inhibitor agent, glucose, xanthan gum, triterpene saponin liquid air-entraining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com