Clean flame-retardant and smoke-suppressive epoxy resin nanocomposite material and preparation method thereof

A nano-composite material and epoxy resin technology, applied in the field of new materials, can solve the problems of smoke suppression and poor mechanical properties, and achieve the effects of good smoke suppression performance, improved flame retardant performance, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

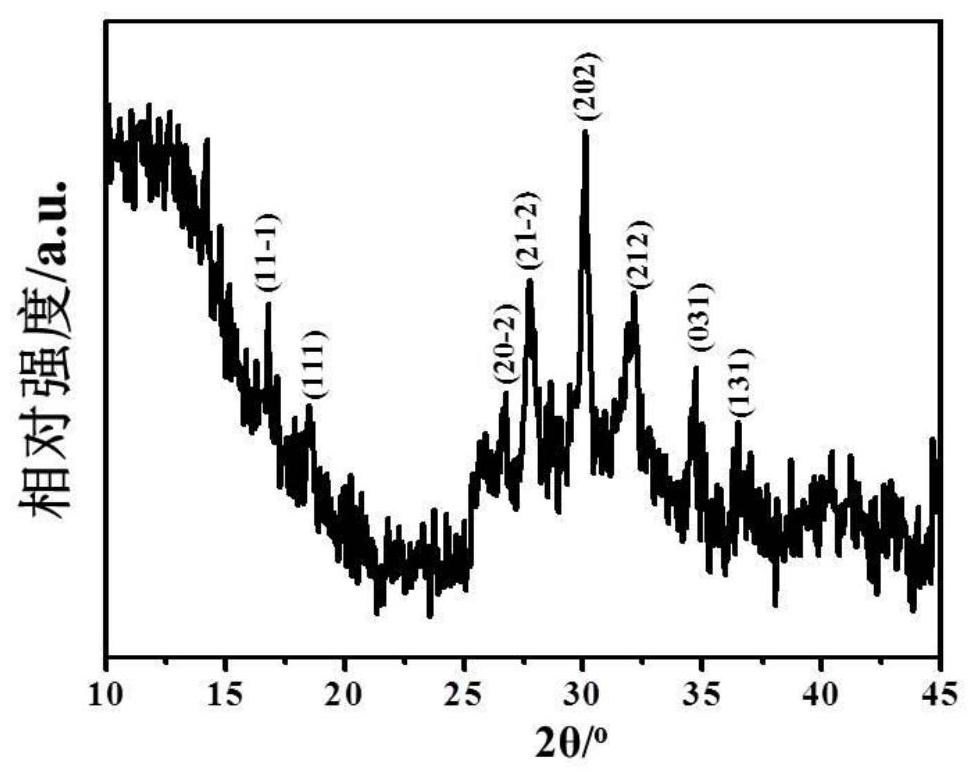

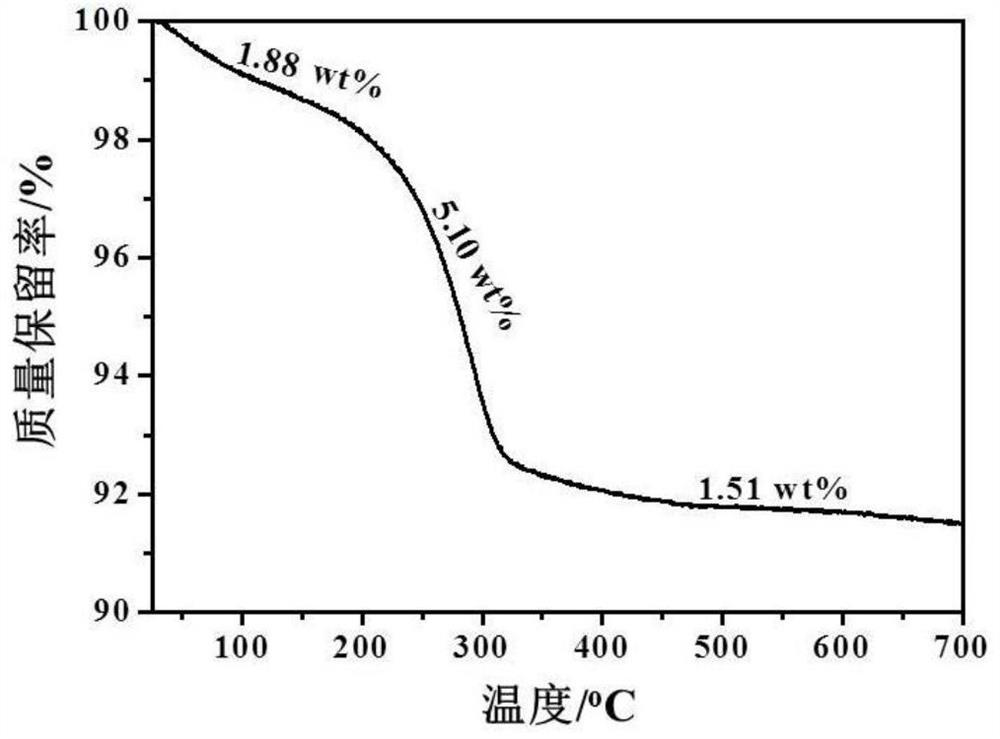

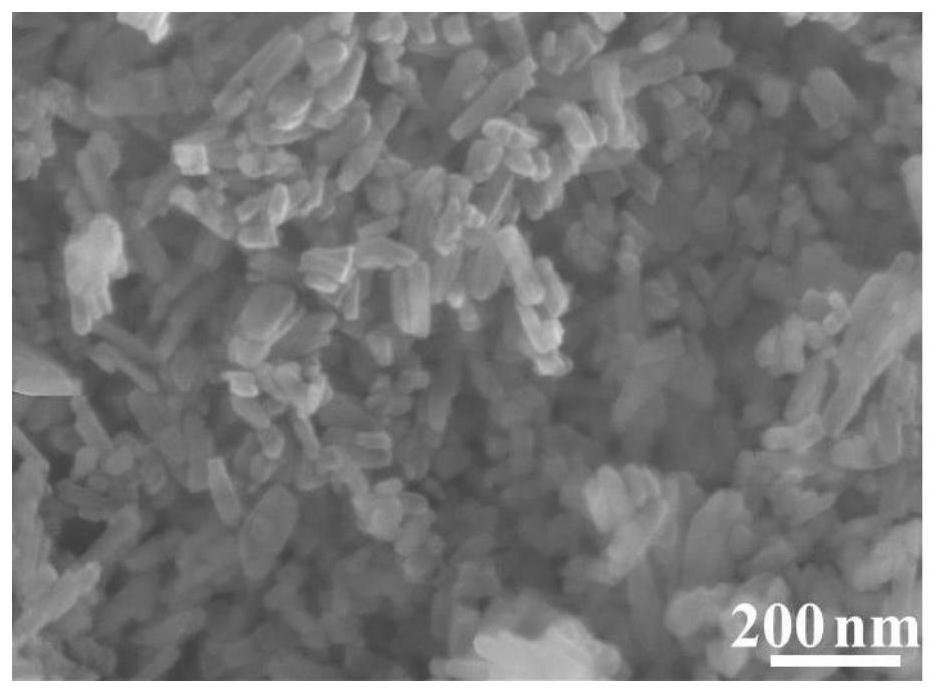

[0035] During the experiment, 0.249 g of cobalt acetate, 0.384 g of potassium pyrophosphate and 3.730 g of potassium chloride were mixed with 15 mL of deionized water. Stir at room temperature for 30 min. Then the mixture was transferred into a tetrafluoroethylene-lined autoclave with a capacity of 50 mL, sealed and heated at 120 °C for 4 hours, washed with deionized water for several times, and then dried at 60 °C for 12 hours, the obtained product was Potassium cobalt pyrophosphate (CPP).

[0036] In the epoxy resin, adding mass fraction is 1, 2, 4, 6, 8, 10 and 12wt% K 2 co 3 (P 2 o 7 ) 2 2H 2 O nanomaterials, in order to achieve a better dispersion state, first disperse CPP in acetone, ultrasonically disperse for 30 minutes until there is no precipitation at the bottom of the beaker, then add epoxy resin to the above solution, continue ultrasonically dispersing for 30 minutes, and then disperse at 90°C Remove the acetone until a homogeneous system is formed, then ad...

Embodiment 2

[0056] The difference from Example 1 is that, according to epoxy resin (Epoxy NPEL128 and DDM are 4:1 by mass ratio) and K 2 co 3 (P 2 o 7 ) 2 2H 2 The mass ratio of O nanomaterials is 100:0, Epoxy NPEL128 and DDM are evenly mixed, and solidified to prepare pure EP. Basic parameters of flame retardant and smoke suppression: UL94 test is not yet flame retardant, there is dripping, the oxygen index is 25.8, and the peak heat release rate is 1073.0kW / m 2 , the total heat release is 92.5MJ / m 2 , the peak smoke release rate is 0.33m 2 / s, the total smoke emission is 24.8m 2 .

Embodiment 3

[0058] The difference from Example 1 is that, according to epoxy resin (Epoxy NPEL128 and DDM are 4:1 by mass ratio) and K 2 co 3 (P 2 o 7 ) 2 2H 2 O nanomaterial mass ratio is 99:1, Epoxy NPEL128, K 2 co 3 (P 2 o 7 ) 2 2H 2 O and DDM were uniformly mixed and solidified to prepare EP / 1wt%CPP nanocomposite. Compared with pure EP, the flame retardant and smoke suppression properties of the obtained composite materials are improved. The basic parameters: UL94 test shows no flame retardant grade, there is dripping phenomenon, the oxygen index is increased to 27.2, and the peak heat release rate is reduced to 983.6kW / m 2 , the total heat release is reduced to 84.6MJ / m 2 , the peak value of smoke release rate is reduced to 0.28m 2 / s, the total smoke emission is reduced to 23.6m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com