A Silicon/Phosphorus Synergistic Flame Retardant Polyamide Resin

A flame retardant polyamide and polyamide technology, applied in the field of flame retardant, can solve the problems of gas phase flame retardant effect failure, low flame retardant efficiency, and decreased mechanical properties of the matrix, and achieve peak heat release rate reduction, halogen-free and environmentally friendly flame retardant Effects of performance and fire risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

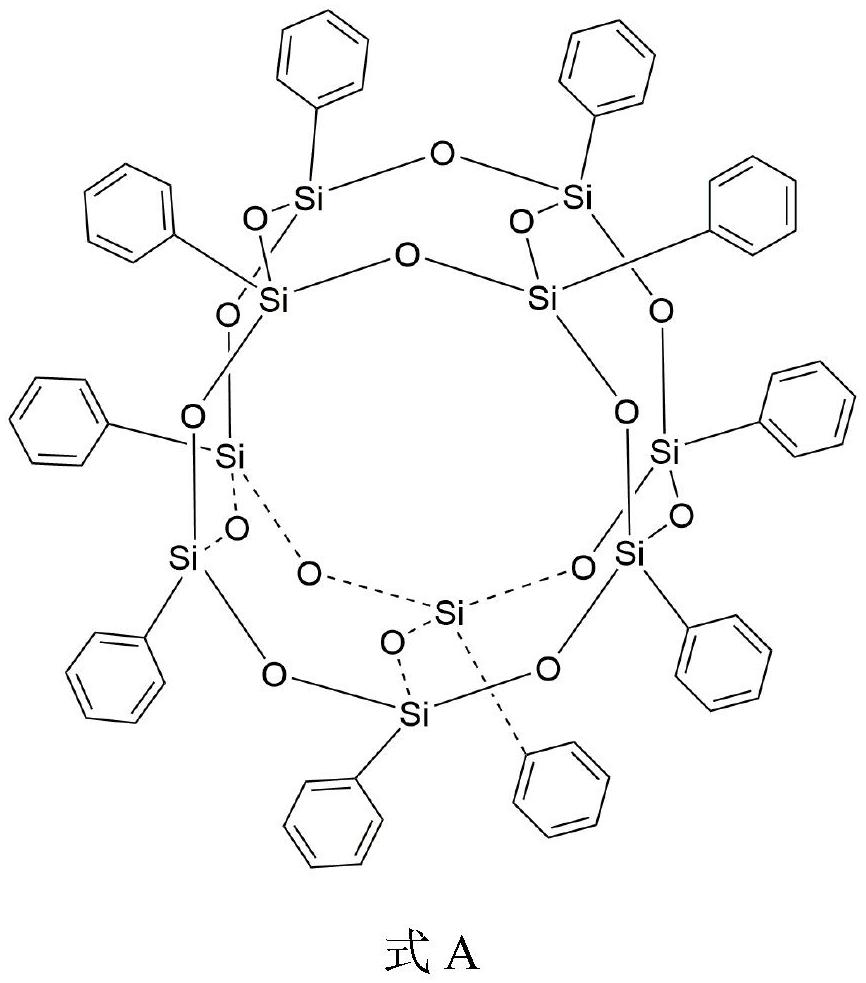

[0036]Weigh 894g of PA6 (Jiangsu Ruimeifu, MF-700, including 50g of PA6 masterbatch), 75g of aluminum diethylphosphinate (Clariant), 25g of octaphenyl POSS (Beijing Institute of Technology Flame Retardant Technology Co., Ltd.) , 4g antioxidant 1010 (BASF company), 2g antioxidant 1076 (BASF company), dried 5 hours standby in 90 ℃ of vacuum ovens, twin-screw extruder rotating speed 50r / min (Germany Brabender reaction type extruder, Screw diameter 20mm), temperature setting: zone 1 245°C, zone 2 245°C, zone 3 250°C, zone 4 250°C, zone 5 250°C, head temperature 245°C. Add the pre-mixed uniform raw materials into the twin-screw extruder, cool, and cut into pellets for later use. The temperature setting of the injection molding machine: 250°C for the first zone, 255°C for the second zone, 255°C for the third zone, 255°C for the fourth zone, and 250°C for the fifth zone , injection pressure 80MPa, cooling time 12 seconds, injection molded standard test samples for testing (limiting o...

Embodiment 2

[0038] Weigh 889g PA66 (Shenma Group EPR24), 75g aluminum triisopropylphosphinate (Clariant), 25g octaphenyl POSS (Beijing Institute of Technology Flame Retardant Technology Co., Ltd.), 4g antioxidant 1010 (BASF) , 2g antioxidant 168 (BASF), 5g anti-dripping agent (Beijing Institute of Technology Flame Retardant Technology Co., Ltd.), dried in a vacuum oven at 90°C for 5 hours for later use, internal mixer speed 40r / min (Shanghai Kechuang XSS- 300), the temperature is 280°C. Add the pre-mixed uniform raw materials to the internal mixer for blending, and press into tablets for later use. LOI is 34.0%, UL94 V-0 level, peak heat release rate 321.2kW / m 2 , the total smoke emission is 935m 2 / m 2 , Notched impact strength 93.2J / m.

Embodiment 3

[0040] Weigh 589g PA6 (Jiangsu Ruimeifu, MF-700), 75g aluminum diethylphosphinate (Clariant), 25g decaphenyl POSS (Beijing Institute of Technology Flame Retardant Technology Co., Ltd.), 300g long glass fiber (Big Stone Group), 4g antioxidant 1098 (BASF), 2g antioxidant 168 (BASF), 5g light stabilizer 770 (Nanjing Jingtianwei Chemical Co., Ltd.) processing method, test method and equipment model are with embodiment 1. LOI is 31.3%, UL94 V-0 level, peak heat release rate 335.2kW / m 2 , the total smoke emission is 1157m 2 / m 2 , Notched impact strength 98.2J / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release rate | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com