Preparation method and application of sulfhydrylation biochar for repairing heavy metal polluted water and soil

A sulfhydryl compound and biochar technology is applied in the restoration, application, soil conditioning materials and other directions of polluted soil, which can solve the problems of unfavorable scale application, complicated preparation process, high pharmaceutical price, etc., and achieves short treatment time and low preparation cost. , stable passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

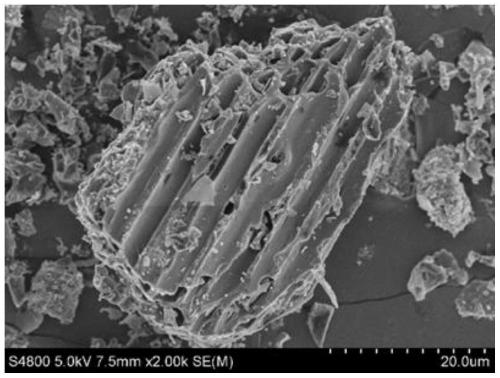

[0032] Embodiment 1, the preparation of thiolated biochar

[0033] The preparation method of a kind of thiolated biochar provided by the embodiment of the present invention comprises:

[0034] (1) Preparation of biochar: Dry and crush rice straw, heat up to 500°C at a rate of 20°C / min under anaerobic or anaerobic conditions, thermally crack until complete carbonization, cool naturally, and grind through a 60-mesh sieve , take the first sieve to obtain biochar.

[0035] (2) Mix 1 g of biochar prepared in step (1) with 4 mL of β-mercaptoethanol, add 2.8 mL of acetic anhydride and 0.2 mL of concentrated sulfuric acid, mix in a constant temperature water bath at 80°C for 18 hours, and cool to room temperature The mixture was washed with water and suction filtered, dried at 35°C for 18 hours, ground through a 60-mesh sieve, and the first sieve was taken to obtain thiolated biochar.

[0036] The esterification reaction of the above-mentioned thiol-treated biochar during the thiol ...

Embodiment 2

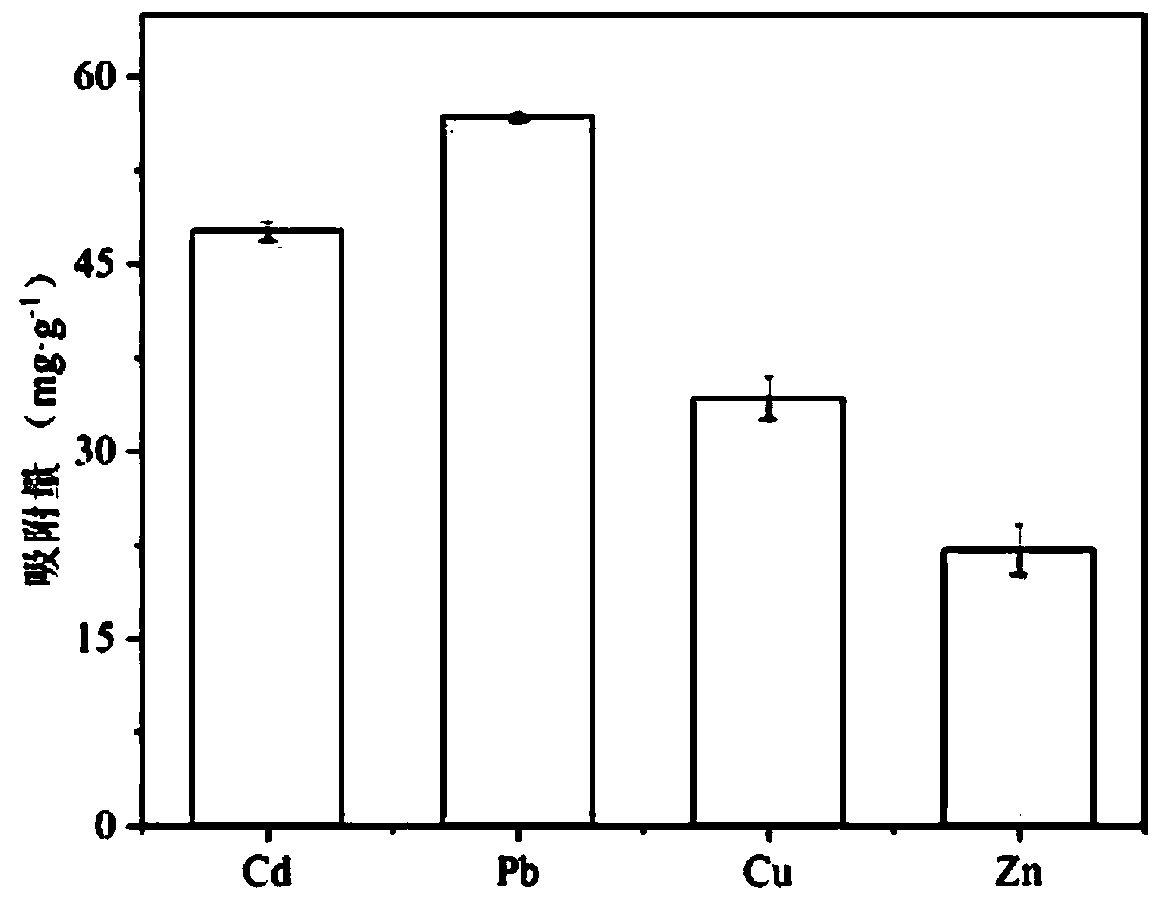

[0039] Example 2 Adsorption effect of thiolated biochar on single cadmium, lead, copper and zinc

[0040] At pH=5, the concentration is 0.05 mol•L -1 The acetic acid-sodium acetate buffer solution was used as a solvent to prepare cadmium ions, lead ions, copper ions and zinc ions at a concentration of 500 mg·L -1 single heavy metal contaminated solution. Accurately weigh a certain amount of thiolated biochar prepared in Example 1 and place it in a 15 mL centrifuge tube, add a certain volume of cadmium, lead, copper and zinc single heavy metal contamination solution at a solid-to-liquid ratio of 1:400, and centrifuge Tube placed at 25°C, 180 r·min -1 Under the condition of shaking for 24h.

[0041] Such as image 3The results showed that the adsorption capacity of thiolated biochar on cadmium ions, lead ions, copper ions and zinc ions in a single heavy metal-contaminated solution was 47.62 mg·g -1 , 56.67 mg·g -1 , 34.23 mg·g -1 and 22.14 mg g -1 . This indicated that ...

Embodiment 3

[0042] Example 3 Adsorption effect of thiolated biochar on complex pollution of cadmium, lead, copper and zinc

[0043] At pH=5, the concentration is 0.05 mol•L -1 The acetic acid-sodium acetate buffer solution was used as a solvent to prepare cadmium ions, lead ions, copper ions and zinc ions at a concentration of 500 mg L -1 Heavy metal compound polluted solution. Accurately weigh a certain amount of thiolated biochar prepared in Example 1 and place it in a 15 mL centrifuge tube, add a certain volume of heavy metal pollution solution of cadmium, lead, copper and zinc at a solid-to-liquid ratio of 1:400, and place the centrifuge tube Placed at 25°C, 180 r·min -1 Under the condition of shaking for 24h.

[0044] Such as Figure 4 As shown, the final adsorption capacity of thiolated biochar on cadmium ions, lead ions, copper ions and zinc ions in the heavy metal complex pollution solution was 13.98 mg g -1 , 14.20 mg·g -1 , 30.35 mg·g -1 and 7.59 mg·g -1 . This indicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com