Separator for lithium battery and preparation method thereof

A lithium battery and diaphragm technology, applied in the field of lithium battery diaphragm and its preparation, can solve the problems of lithium ion battery performance degradation, poor electrolyte wettability, poor thermal stability, etc., and achieve excellent thermal stability and mechanical properties, excellent mechanical properties Excellent performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 7g Kevlar 49 and 7g KOH and add them to 500ml DMSO, seal them with sealant and stir magnetically at room temperature for about a week to obtain a dark red ANF suspension; during the experiment, it was found that the aramid fiber was dissolved During the process, the system presents different states at different time periods, the aramid fiber gradually dissolves, the color of the system gradually deepens, and finally turns dark red, and the ANF suspension is obtained;

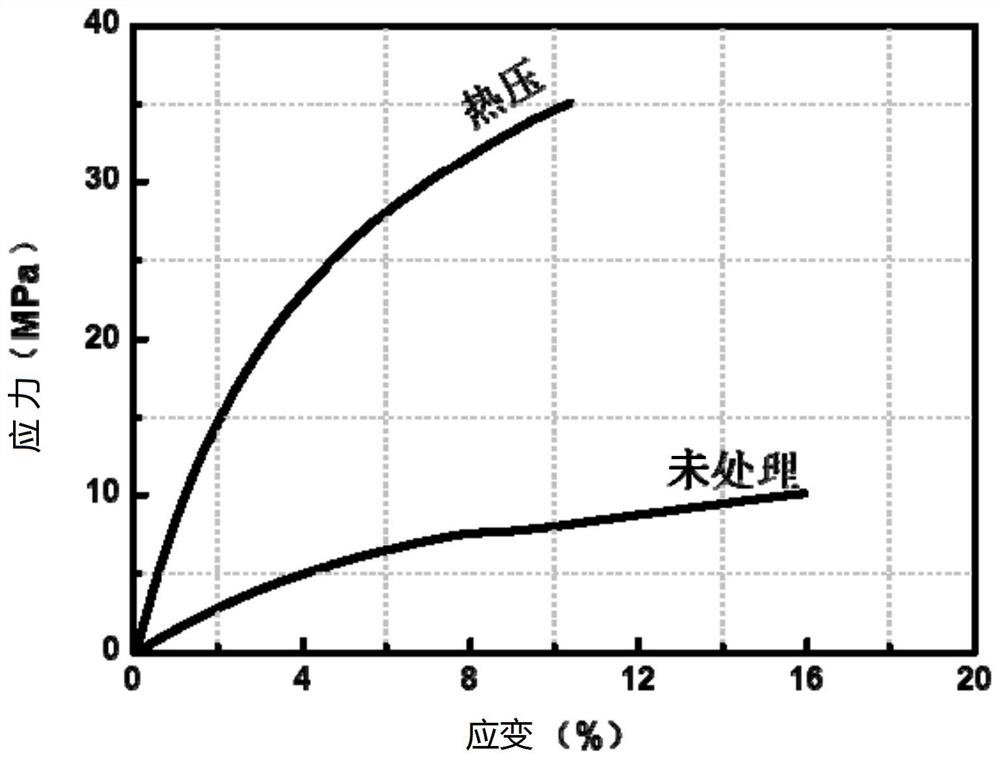

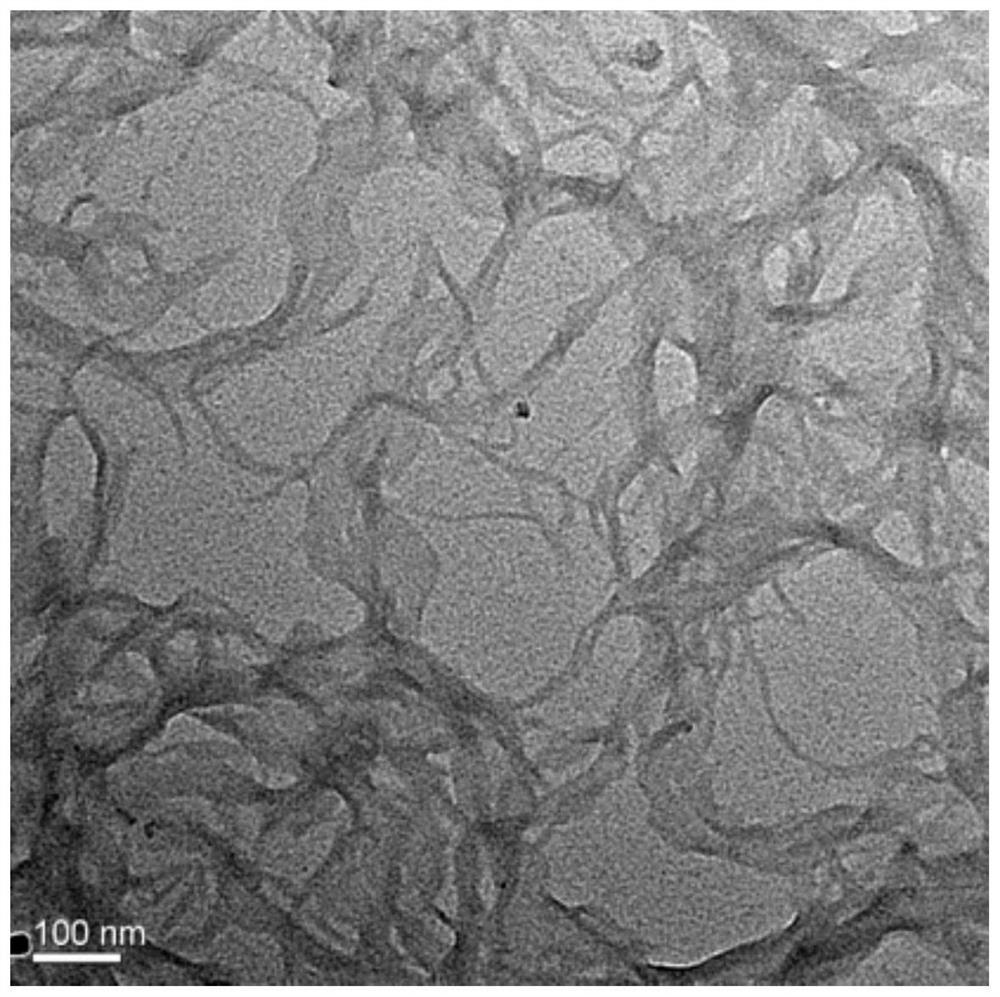

[0044] (2) Centrifuge the ANF suspension in step (1) at a speed of 8000 rad / min and a temperature of 25°C for 45 min to remove undissolved KOH and aramid fibers in the suspension, and prepare a concentration of 2.159 wt%. ANF / DMSO solution; figure 1 It is the transmission electron microscope picture of the ANF / DMSO solution obtained in Example 1. In the figure, the existence of nanofibers in the ANF solution can be clearly observed, and a relatively good structural shape is maintained; it shows ...

Embodiment 2

[0049] (1) Weigh 8g Kevlar 49 and 10g KOH respectively and add to 500ml DMSO, seal with sealant and stir magnetically at room temperature for about a week to obtain dark red ANF suspension.

[0050] (2) Centrifuge the ANF suspension in step (1) at a speed of 8000 rad / min and a temperature of 22° C. for 45 min to remove undissolved KOH and aramid fibers in the suspension to prepare 2.365 wt % concentration of ANF ANF / DMSO solution.

[0051] (3) Dilute the ANF solution of the 2.365wt% concentration obtained in step (2) to a 1.5wt% concentration, then add the PEO of 1,000,000 molecular weights with the same quality as ANF, that is, the para-aramid fiber: the mass ratio of PEO is 1 : 1. After being heated and mechanically stirred in a water bath at 50°C, a uniformly mixed spinning solution is obtained.

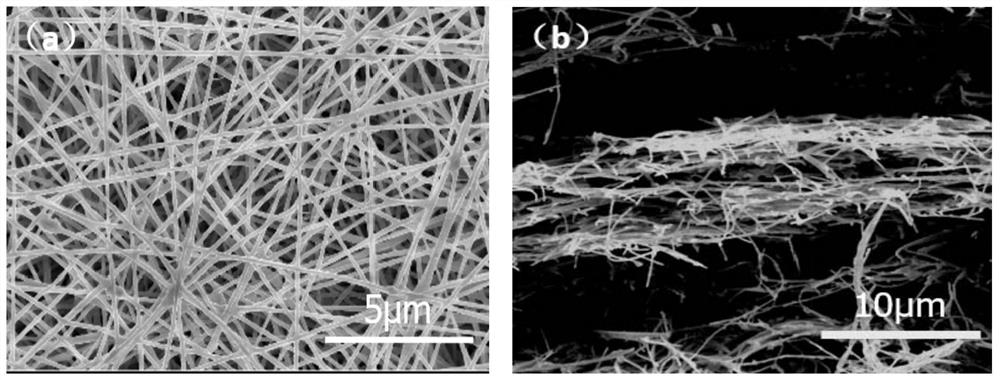

[0052] (4) Take an appropriate amount of the spinning solution of step (3) with a 5ml diameter syringe of 12.5mm, and use a needle with an inner diameter of 0.2mm and an outer di...

Embodiment 3

[0057] (1) Weigh 8g Kevlar 49 and 10g KOH respectively and add to 500ml DMSO, seal with sealant and stir magnetically at room temperature for about a week to obtain dark red ANF suspension.

[0058] (2) Centrifuge the ANF suspension in step (1) at a speed of 8000 rad / min and a temperature of 22° C. for 45 min to remove undissolved KOH and aramid fibers in the suspension to prepare 2.365 wt % concentration of ANF ANF / DMSO solution.

[0059] (3) Dilute the ANF solution of the 2.365wt% concentration obtained in step (2) to a 1.5wt% concentration, then add the PEO of 1,000,000 molecular weights with the same quality as ANF, that is, the para-aramid fiber: the mass ratio of PEO is 1 : 1. After being heated and mechanically stirred in a water bath at 50°C, a uniformly mixed spinning solution is obtained.

[0060] (4) Take an appropriate amount of the spinning solution of step (3) with a 5ml diameter syringe of 12.5mm, and use a needle with an inner diameter of 0.2mm and an outer di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com