Supercapacitor-used nickel vanadate material, preparation method thereof and application

A supercapacitor, nickel vanadate technology, applied in chemical instruments and methods, hybrid capacitor electrodes, vanadium compounds, etc., can solve the problems of poor conductivity and surface permeability, few reactive sites, low cycle retention rate, etc., to achieve Low electrochemical impedance, good capacitance retention, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

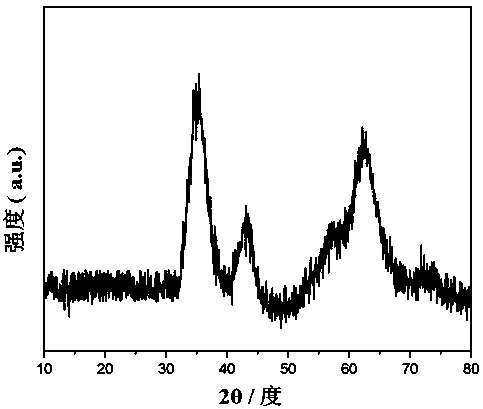

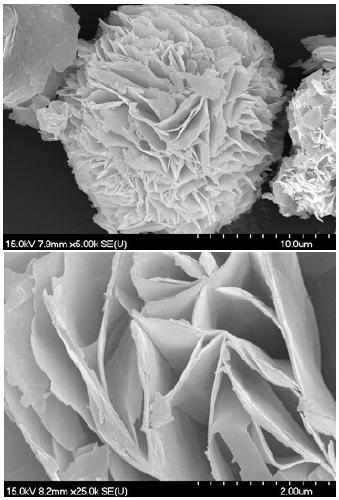

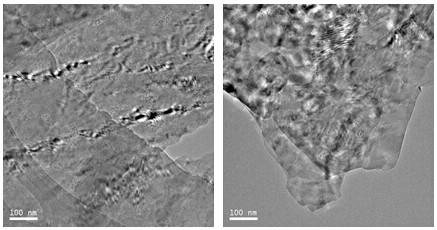

[0047] 4 mmol NH 4 VO 3 Completely dissolved in the solvent, the solvent is an aqueous solution of ethanol, the volume ratio of ethanol to water is 0.5:1; after ultrasonic treatment for 30 minutes, add 6 mmol Ni (NO 3 ) 2 ·6H 2 O, to obtain the reaction precursor. Adjust the pH to about 9 with a basic structure-directing agent (ethanolamine aqueous solution), and continue stirring in a water bath for 20 min to obtain a reaction mixture. Transfer the reaction mixture to a 100 mL Teflon-lined stainless steel autoclave. After heating and maintaining at 150° C. for 10 hours, it was naturally cooled to room temperature. After centrifugal separation, the synthesized substance was washed several times with deionized water and ethanol, and dried in a vacuum oven at 60° C. for 16 hours to obtain solid nickel vanadate.

[0048] Weigh the nickel vanadate material, acetylene black and PVDF prepared above at a mass ratio of 8:1:1, mix and grind, add a few drops of N-methylpyrrolidone...

Embodiment 2

[0057] 4 mmol NH 4 VO 3 It is completely dissolved in a solvent, the solvent is an aqueous solution of ethanol, and the volume ratio of ethanol to water is 1:1. After sonication for 30 min, 6 mmol Ni(NO 3 ) 2 ·6H 2 O. Adjust the pH value to about 7 with a basic structure-directing agent (ethanolamine aqueous solution), and continue stirring in a water bath for 20 min. Transfer the resulting mixture into a 100 mL Teflon-lined stainless steel autoclave. After heating and maintaining at 150° C. for 10 hours, it was naturally cooled to room temperature. The solid and liquid were separated, and the synthesized substance was washed several times with deionized water and ethanol, and dried in a vacuum oven at 70° C. for 12 hours to obtain solid nickel vanadate. The solid powder is tested by SEM, and the structure is block particles.

Embodiment 3

[0059] 3 mmol NH 4 VO 3 It is completely dissolved in a solvent, the solvent is an aqueous solution of ethanol, and the volume ratio of ethanol to water is 0.3:1. After sonication for 30 min, 6 mmol Ni (NO 3 ) 2 ·6H 2 O. Adjust the pH value to about 8 with a basic structure-directing agent (ethanolamine aqueous solution), and continue stirring in a water bath for 20 min. Transfer the resulting mixture into a 100 mL Teflon-lined stainless steel autoclave. After heating and maintaining at 150° C. for 10 hours, it was naturally cooled to room temperature. Solid-liquid separation, the synthesized substance was washed several times with deionized water and ethanol, and dried in a vacuum oven at 70° C. for 24 hours to obtain nickel vanadate solid. The solid powder is tested by SEM, and the structure is a uniformly dispersed lamellar structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com