Preparation method of cetomacrogol 1000

A polyethylene glycol and drying technology, which is applied in the preparation field of Situ Mage 1000, can solve the problems of Situ Mage 1000 industrial production difficulties, harsh storage and transportation conditions of ethylene oxide, and low safety, so as to avoid Inflammable and explosive, easy to operate and safe, high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

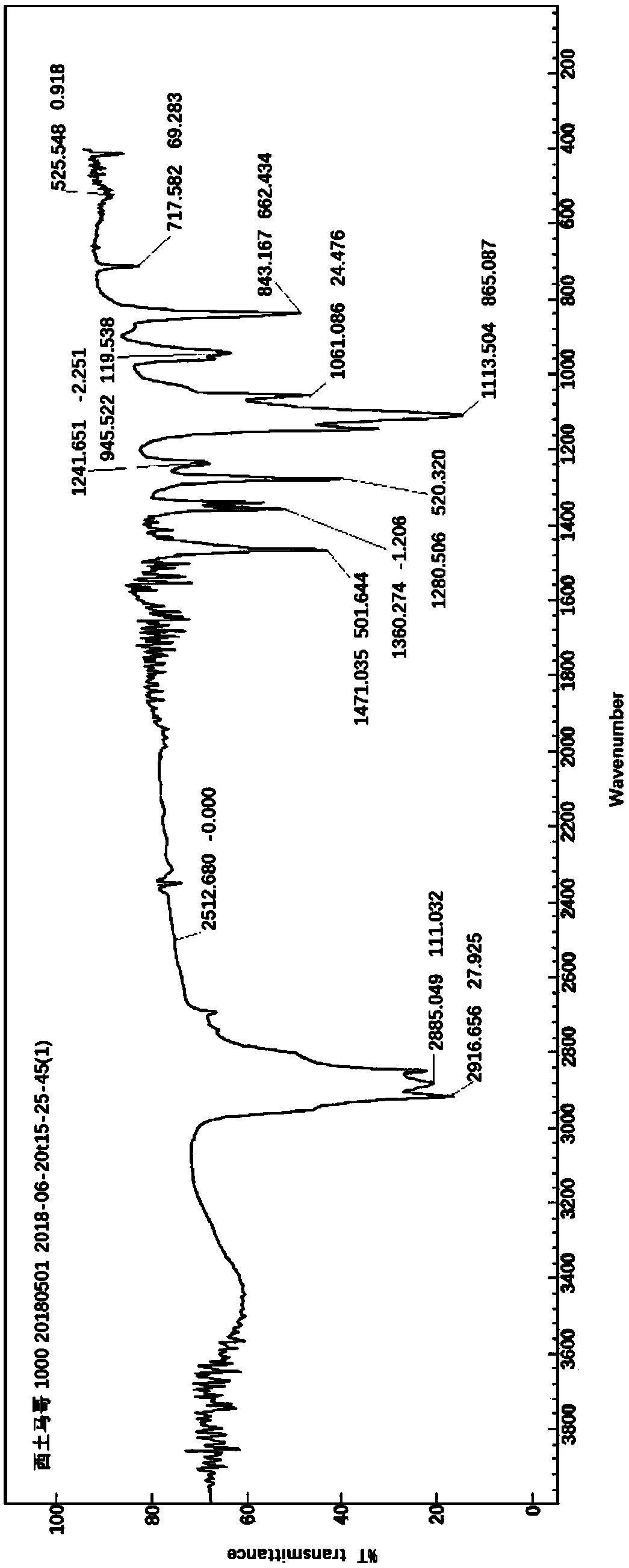

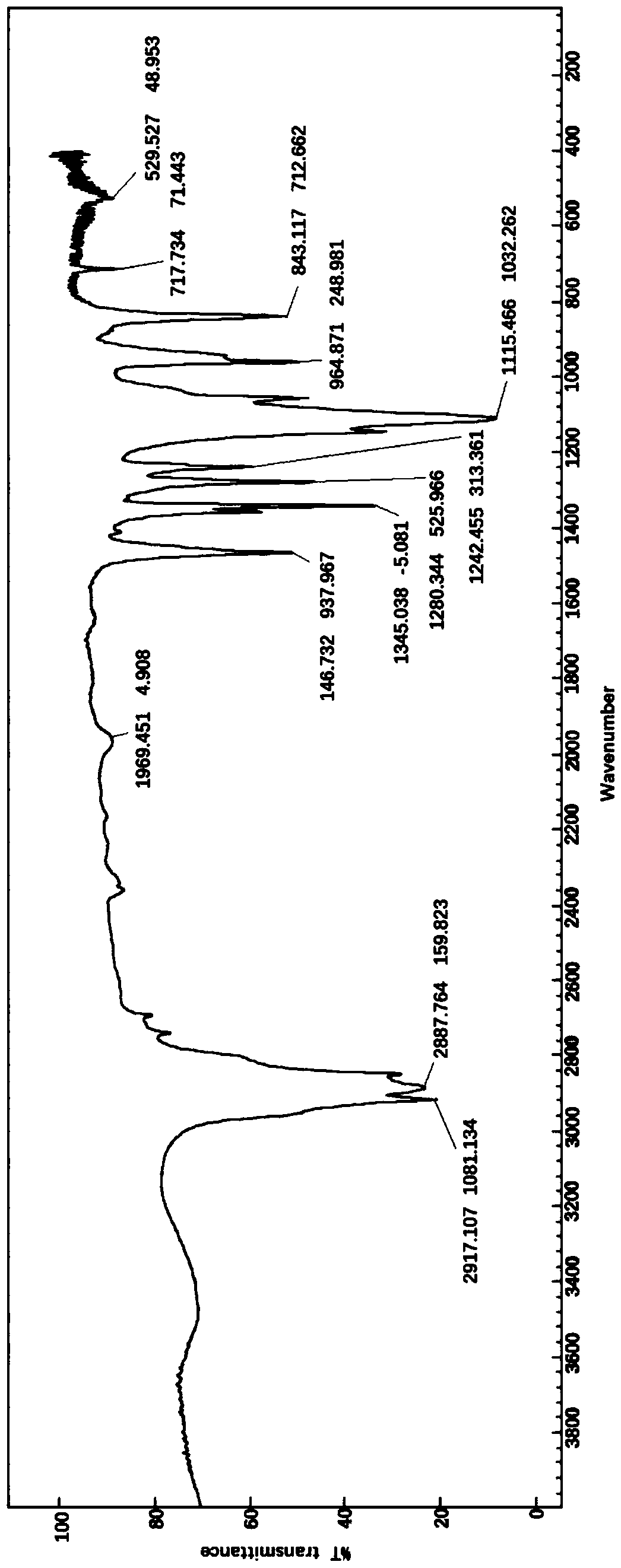

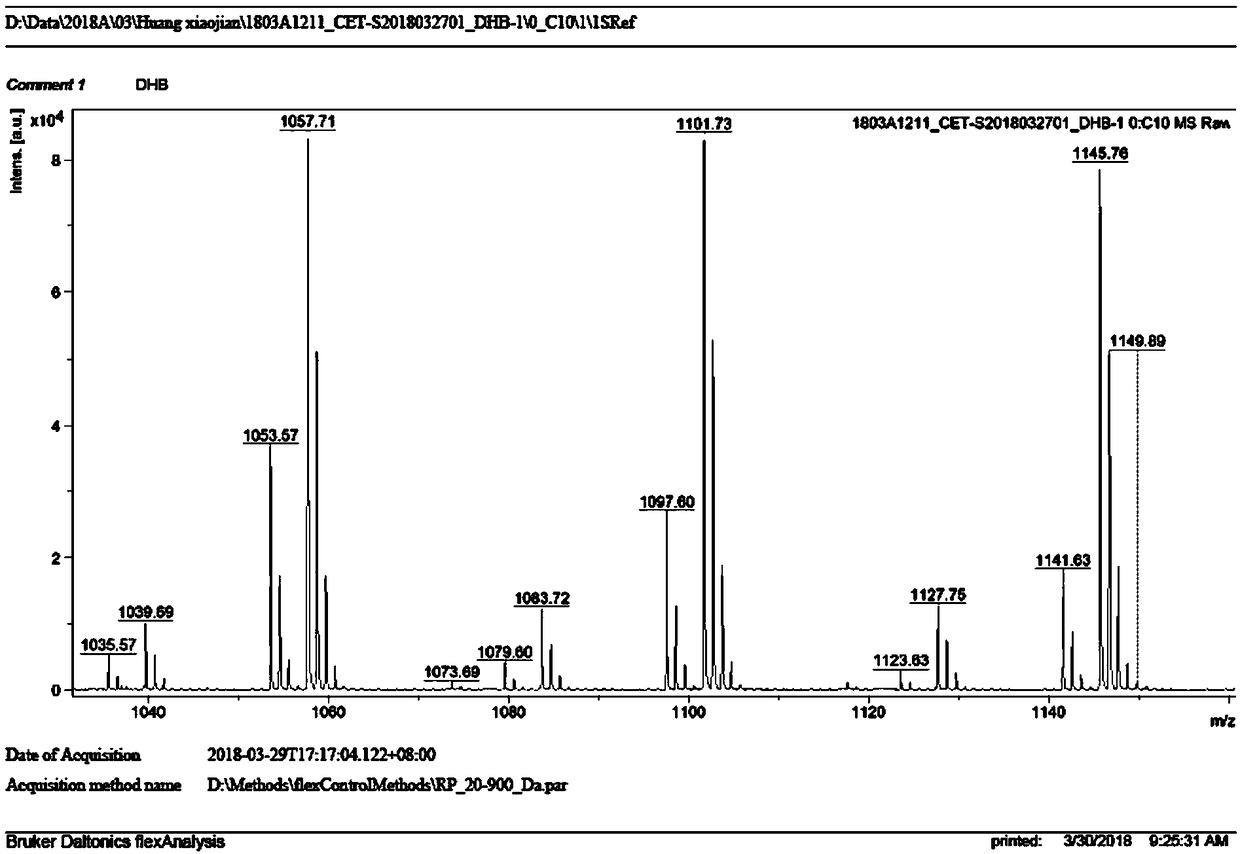

Image

Examples

Embodiment 1

[0031] The preparation method of embodiment 1 Situ Ma Ge 1000

[0032] (1) Polyethylene glycol 800 (157.50g, 191.61mmol, 1eq) was dissolved in dry tetrahydrofuran (2L), under nitrogen protection, and metal sodium (4.85g, 210.77mmol, 1.1 eq), heated to reflux for 20h.

[0033] (2) The reaction solution was cooled to room temperature, and hexadecane bromide (64.36 g, 210.77 mmol, 1.1 eq) was added dropwise. After the addition was complete, the mixture was heated under reflux for 20 h.

[0034] (3) The reaction liquid was cooled to room temperature, filtered, and the filtrate was concentrated to dryness to obtain the crude product of Situmage 1000.

[0035] (4) Dissolve the crude product of Situmage 1000 in ethyl acetate (100mL), add dropwise n-heptane (1000mL), stir at room temperature overnight, after the solid precipitates, filter and dry in vacuum to obtain Situmage 1000 (122.00g) , the yield of West Macco 1000 was 55%.

[0036] Wherein, the heating temperature of the heat...

Embodiment 2

[0037] The preparation method of embodiment 2 Situ Mage 1000

[0038] (1) Polyethylene glycol 800 (157.50g, 191.61mmol, 1eq) was dissolved in dry dichloromethane (2L), under nitrogen protection, and metal sodium (4.85g, 210.77 mmol, 1.1eq), heated at reflux at 45°C for 20h.

[0039] (2) The reaction solution was cooled to room temperature, and hexadecane bromide (64.36 g, 210.77 mmol, 1.1 eq) was added dropwise. After the addition was complete, the mixture was heated under reflux at 45° C. for 20 h.

[0040] (3) The reaction liquid was cooled to room temperature, filtered, and the filtrate was concentrated to dryness to obtain the crude product of Situmage 1000.

[0041] (4) Dissolve the crude product of Situmage 1000 in ethyl acetate (100mL), add dropwise n-heptane (1000mL), stir at room temperature overnight, after the solid precipitates, filter and dry in vacuo to obtain Situmage 1000 (110.28g) , yield 49.7%.

[0042] In this embodiment, the solvent used is dichlorometha...

Embodiment 3

[0045] The preparation method of embodiment 3 Situ Ma Ge 1000

[0046] (1) Polyethylene glycol 1000 (190g, 190mmol, 1eq) was dissolved in dry tetrahydrofuran (2L), under nitrogen protection, and metal sodium (4.85g, 210.77mmol, 1.1eq) cut into small pieces was added under stirring at room temperature , Heated to reflux at 70°C for 20h.

[0047] (2) The reaction solution was cooled to room temperature, and hexadecane bromide (64.36 g, 210.77 mmol, 1.1 eq) was added dropwise. After the addition was complete, the mixture was heated under reflux at 70° C. for 20 h.

[0048] (3) The reaction liquid was cooled to room temperature, filtered, and the filtrate was concentrated to dryness to obtain the crude product of Situmage 1000.

[0049] (4) The crude product of Situmage 1000 was dissolved in ethyl acetate (100mL), added dropwise with n-heptane (1000mL), stirred overnight at room temperature, after the solid precipitated, filtered, and vacuum-dried to obtain Situmage 1000 (145.17g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com