Self-repairing high-durability anticorrosive composite coating and preparation method thereof

A composite coating and self-repairing technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of reducing the service life of coatings, cracking and falling off of paint films, and the inability of coatings to exert significant energy-saving benefits. Reduced attenuation of solar heat reflection efficiency, excellent adhesion and salt spray resistance, and excellent solar heat reflection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) Preparation of solvent A

[0081] Mix xylene and n-butanol evenly in a weight ratio of 7:3 to obtain solvent A

[0082] (2) Preparation of nano-modified epoxy zinc-rich primer

[0083] Put 8 parts of solvent A, 0.5 parts of dispersant (Efka PU 4010N), 6 parts of solid epoxy resin (DER 671-x75) and 4 parts of modified liquid epoxy resin (KD-175X90) into the stirring tank in sequence, at 250rpm Stir for 10 minutes at a high speed, then add 50 parts of zinc powder, 2.1 parts of nano-ZnO (3005029) and 0.9 parts of nano-Al 2 o 3 (1301001), stirred at 650rpm for 30min, then added 0.3 parts of defoamer (BYK-052N), 2 parts of anti-settling agent (3300), stirred at 450rpm for 20min, and obtained nano-modified epoxy zinc-rich bottom Paint component A; then prepare 3 parts of modified polyamide epoxy curing agent (Ancamide 2634) as component B; mix the above components A and B together, add 15 parts of diluent A, stir for 3 minutes and mix well , to obtain the nano-modifie...

Embodiment 2

[0097] (1) Preparation of solvent A

[0098] Mix xylene and n-butanol evenly in a weight ratio of 7:3 to obtain solvent A

[0099] (2) Preparation of nano-modified epoxy zinc-rich primer

[0100] Put 12 parts of solvent A, 0.5 parts of dispersant (Efka PU 4010N), 6 parts of solid epoxy resin (DER 671-x75) and 12 parts of modified liquid epoxy resin (KD-175X90) into the stirring tank successively, at 350rpm Stir for 10 minutes at a high speed, then add 80 parts of zinc powder, 5.6 parts of nano-ZnO (3005029) and 2.4 parts of nano-Al 2 o 3 (1301001), stirred at a speed of 750rpm for 30min, then added 0.3 parts of defoamer (BYK-052N), 2 parts of anti-settling agent (3300), stirred at a speed of 500rpm for 20min, and obtained nano-modified epoxy zinc-rich bottom Paint component A; then prepare 7 parts of modified polyamide epoxy curing agent (Ancamide 2634) as component B; mix the above components A and B together, add 25 parts of thinner A, stir for 3 minutes and mix well , t...

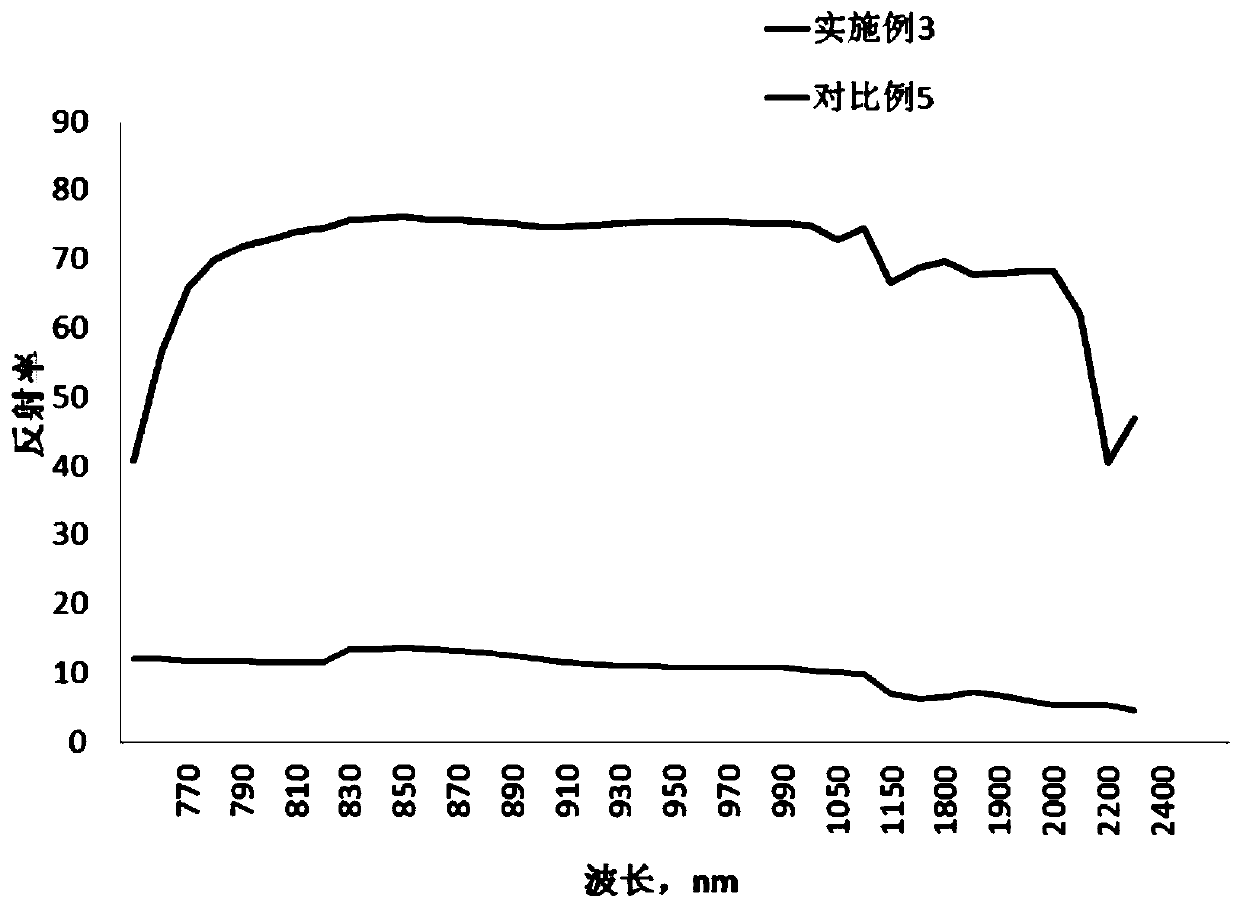

Embodiment 3

[0114] (1) Preparation of solvent A

[0115] Mix xylene and n-butanol evenly in a weight ratio of 7:3 to obtain solvent A

[0116] (2) Preparation of nano-modified epoxy zinc-rich primer

[0117] Put 10 parts of solvent A, 0.5 parts of dispersant (Efka PU 4010N), 8 parts of solid epoxy resin (DER 671-x75) and 6 parts of modified liquid epoxy resin (KD-175X90) into the stirring tank in sequence, at 300rpm Stir for 10 minutes at a high speed, then add 70 parts of zinc powder, 4.2 parts of nano-ZnO (3005029) and 1.8 parts of nano-Al 2 o 3 (1301001), stirred at 700rpm for 30min, then added 0.3 parts of defoamer (BYK-052N), 2 parts of anti-settling agent (3300), stirred at 450rpm for 20min, and obtained nano-modified epoxy zinc-rich bottom Paint component A; then prepare 5 parts of modified polyamide epoxy curing agent (Ancamide 2634) as component B; mix the above components A and B together, add 20 parts of diluent A, stir for 3 minutes and mix well , to obtain the nano-modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com