Novel hindered amine light stabilizer preparation method

A hindered amine light stabilizer, a new type of technology, applied in the direction of rayon manufacturing, single-component polyolefin rayon, fiber chemical characteristics, etc., can solve the problem of heavy taste, achieve good compatibility, processing performance and anti-corrosion Excellent aging effect and fewer steps for product synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

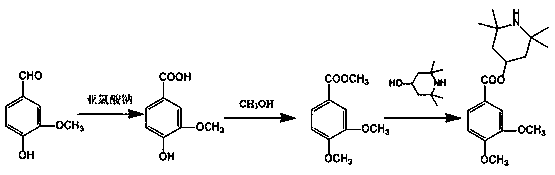

Method used

Image

Examples

Embodiment 1

[0028] Add 300g of toluene as a solvent, 76.08g of vanillin, 45.22g of sodium chlorite in a 1000ml four-neck bottle assembled with a condenser, a water separator, a foam blower, a return pipe, a thermometer and an agitator, and open Stir and react at 120°C for 2h. After cooling down to 30°C, add 32.04g of methanol, start stirring, react at 100°C for 2 hours, add 78.63g of tetramethylpiperidinol, raise the temperature to 140°C and continue stirring for 3 hours, then wash with water, decolorize, filter, cool and crystallize to obtain the target Product 136.3g.

[0029] Product evaluation experiment:

[0030] Maximum breaking force before aging (N) Maximum breaking force after aging (N) Fracture Maximum Force Retention % 3‰783 69 43 62.3 3‰ target product 72 51 70.8

Embodiment 2

[0032] Add 400g of toluene as solvent, 152.15g of vanillin, 90.44g of sodium chlorite in a 1000ml four-necked bottle assembled with condenser, water separator, foamer, return pipe, thermometer and stirrer, and open Stir and react at 100°C for 1h. After cooling down to 30°C, add 64.08g of methanol, start stirring, react at 80°C for 1 hour, add 157.25g of tetramethylpiperidinol, raise the temperature to 120°C and continue stirring for 5 hours, then wash with water, decolorize, filter, and cool to crystallize to obtain the target Product 271.2g.

[0033] Product evaluation experiment:

[0034] Maximum breaking force before aging (N) Maximum breaking force after aging (N) Fracture Maximum Force Retention % 3‰783 71 45 63.4 3‰ target product 73 54 73.9

Embodiment 3

[0036] Add 800g of toluene as solvent, 304.3g of vanillin, 180.88g of sodium chlorite in a 2000ml four-necked bottle assembled with condenser, water separator, foamer, return pipe, thermometer and stirrer, and open Stir and react at 60°C for 0.5h. After cooling down to 30°C, add 128.16g of methanol, start stirring, react at 60°C for 0.5h, add 314.5g of tetramethylpiperidinol, raise the temperature to 100°C and continue stirring for 1h, then wash with water, decolorize, filter, and cool to crystallize to obtain Target product 518.9g.

[0037] Product evaluation experiment:

[0038] Maximum breaking force before aging (N) Maximum breaking force after aging (N) Fracture Maximum Force Retention % 3‰783 69 43 62.3 3‰ target product 73 51 69.9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com