Ceramic casing and preparation method thereof as well as electronic equipment

A ceramic shell and ceramic technology, which is applied in the field of ceramic shell and its preparation, can solve the problems of poor sealing and appearance consistency, affecting the appearance and performance of ceramic shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

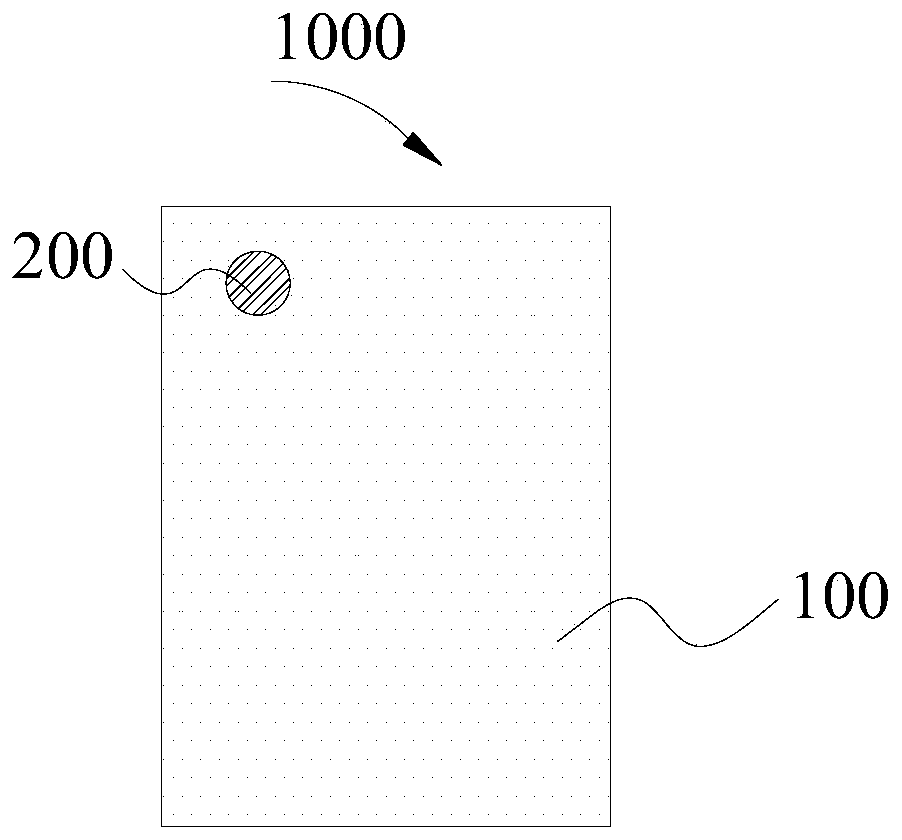

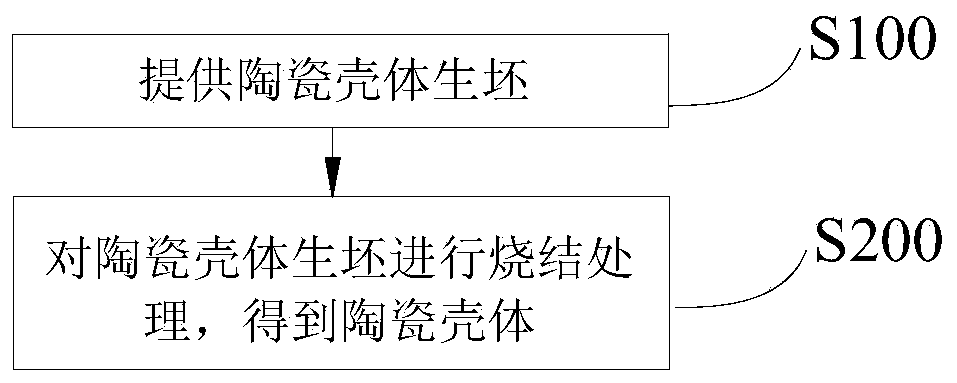

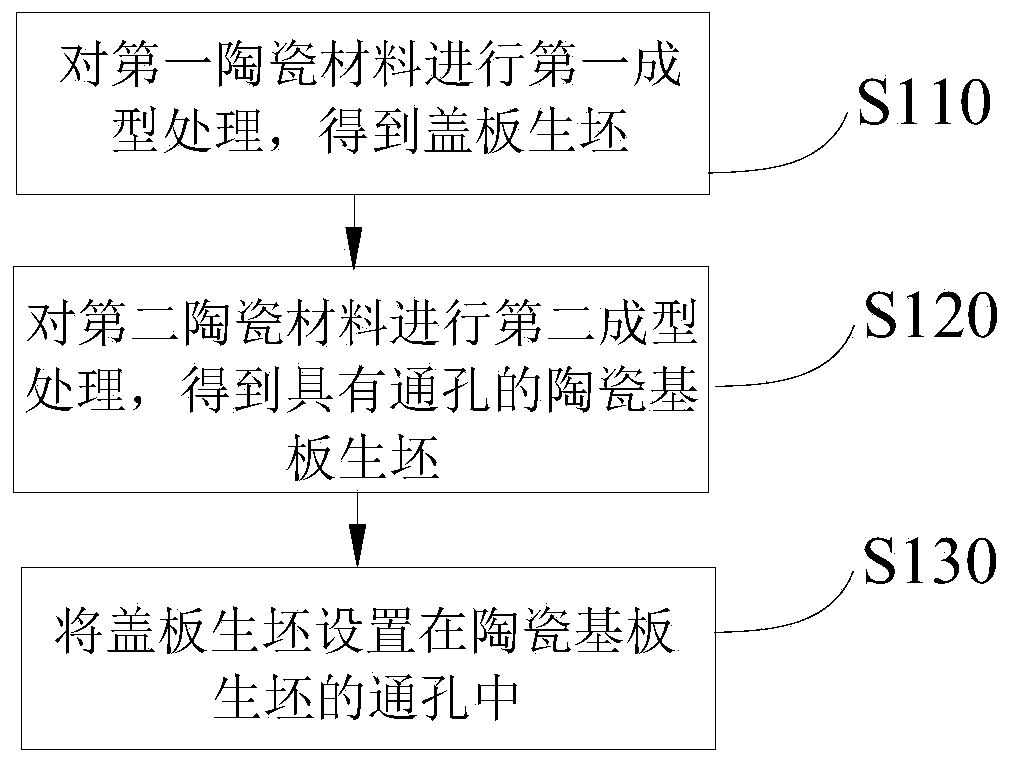

[0034] In this step, a ceramic case green body is provided. Specifically, the ceramic shell green body includes a ceramic substrate green body and a cover plate green body, the ceramic substrate green body has a through hole, and the cover plate green body is disposed in the through hole. Specifically, the preparation method of the ceramic shell green body is not particularly limited, for example, the ceramic shell green body formed by the ceramic substrate green body and the cover plate green body can be formed at one time through an injection molding process. Specifically, the first ceramic material and the second ceramic material can be injection-molded simultaneously through a two-color injection molding process, the first ceramic material can form a cover plate green body, and the second ceramic material can form a ceramic substrate green body. Thus, the ceramic case green body can be easily prepared. For example, after the ceramic substrate green body and the cover plat...

example 1

[0076] (1) 80 parts by weight of cubic phase zirconia powder containing zirconia powder of 80 wt%, 15 parts by weight of yttrium trioxide and 5 parts by weight of titanium dioxide are mixed to form the first ceramic material;

[0077] (2) Injection-molding the first ceramic material formed in the previous step, and performing degreasing treatment at 800°C, and then pre-sintering at 1300°C to obtain a pre-sintered green body for the cover plate. Cutting process to obtain the cover plate green body;

[0078] (3) Injection-molding the pre-configured second ceramic material including tetragonal zirconia, degreasing at 600°C, and then pre-sintering at 1000°C to obtain a calcined ceramic substrate. The ceramic substrate calcined body is cut to obtain a ceramic substrate green body with through holes;

[0079] (5) Place the cover plate green body prepared in the previous step in the through hole of the ceramic substrate green body to form a ceramic shell green body, and sinter the c...

example 2

[0082] Other modes of operation are the same as Example 1, and the difference is that in step (1), 90 parts by weight of zirconia powder containing 75wt% cubic phase zirconia, 10 parts by weight of diyttrium trioxide, 20 parts by weight of diyttrium trioxide, Cerium oxide and 10 parts by weight of titanium dioxide are mixed to form a first ceramic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com