Method and equipment for preventing dioxin generation and achieving ultra-clean emission of flue gas

A flue gas and equipment technology, which is applied in the field of preventing dioxin generation and flue gas ultra-clean emission and equipment, and can solve the problems of difficult HCL, dioxin purification, inability to meet emission standards, and arduous tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

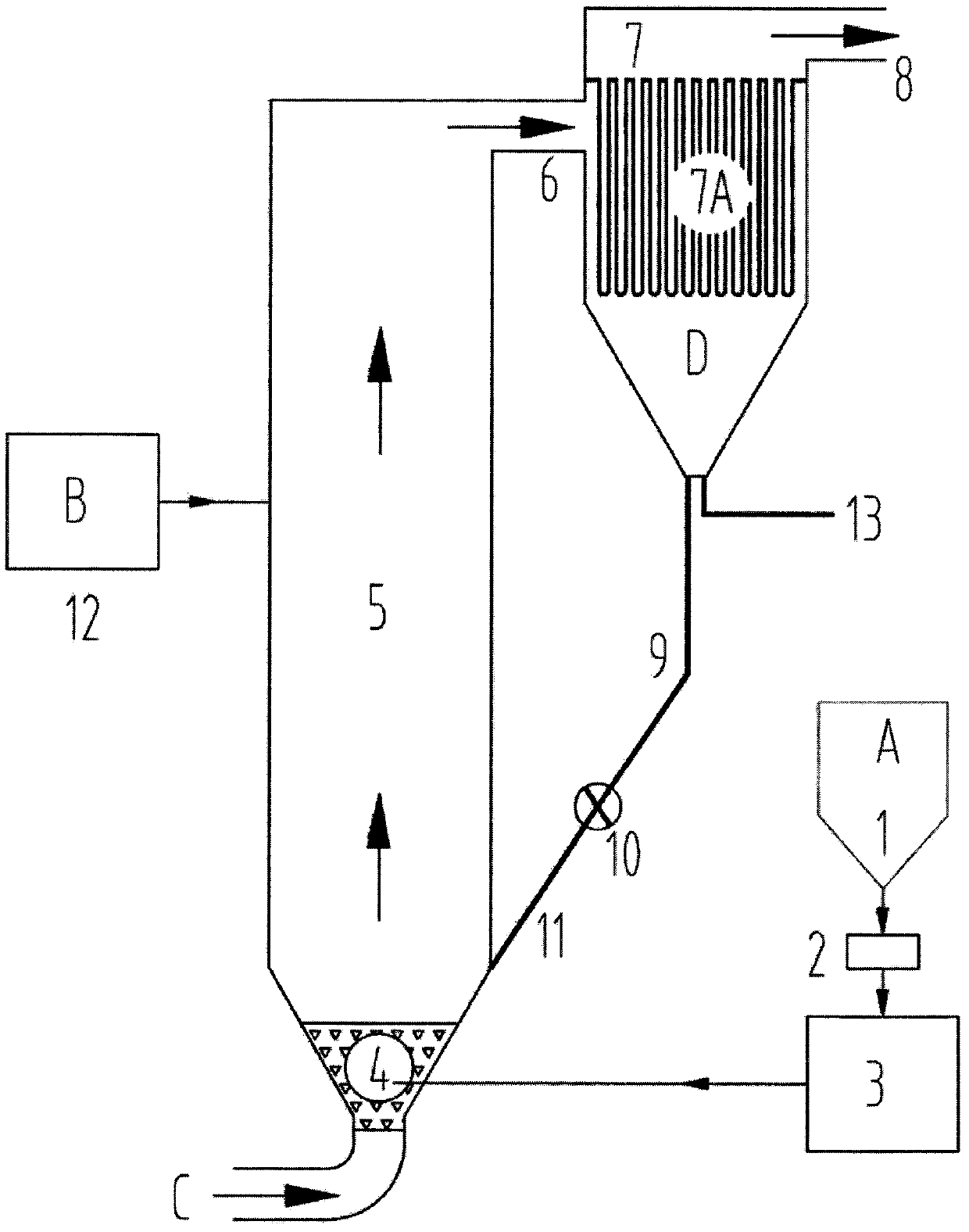

[0021] A method and equipment for preventing dioxin generation and ultra-clean emission of flue gas, comprising: deacidification agent A, denitrification agent B, deacidification agent silo 1, metering feeder 2, pneumatic powder injector 3, Gas-solid mixer 4, dry reaction tower 5, flue 6, ceramic fiber filter tube dust collector 7, flue gas outlet 8, feed pipe 1 9, high temperature mill 10, feed pipe 2 11, denitrification spray ammonia System 12, ash unloading valve 13.

[0022] Deacidification agent A includes Ca(OH) 2 , CaO, Na 2 CO 3 , NaHCO 3 ; where Ca(OH) 2 , CaO, Na 2 CO 3 , NaHCO 3 The object of removal is sulfur and chlorine in the original waste gas; Ca(OH) 2 , the amount of CaO used and sulfur, chlorine molar ratio is 3:1, Na 2 CO 3 , NaHCO 3 The molar ratio of the usage amount to sulfur and chlorine is 1.2:1.

[0023] The denitration agent B includes ammonia water and urea. The use of ammonia water and urea is to remove nitrogen oxides in the original e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com