Dry and wet coupling electrostatic dust collection system and dust collection technology

A dry-wet coupling, electrostatic dust removal technology, applied in the direction of electrostatic separation, electrostatic effect separation, electrode structure, etc., can solve the problems of ultra-clean emission of flue gas particles, the inability of ultra-clean emission of particulate matter, and the reduction of flue gas temperature. The effect of small amount of engineering, ultra-clean emission, and avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

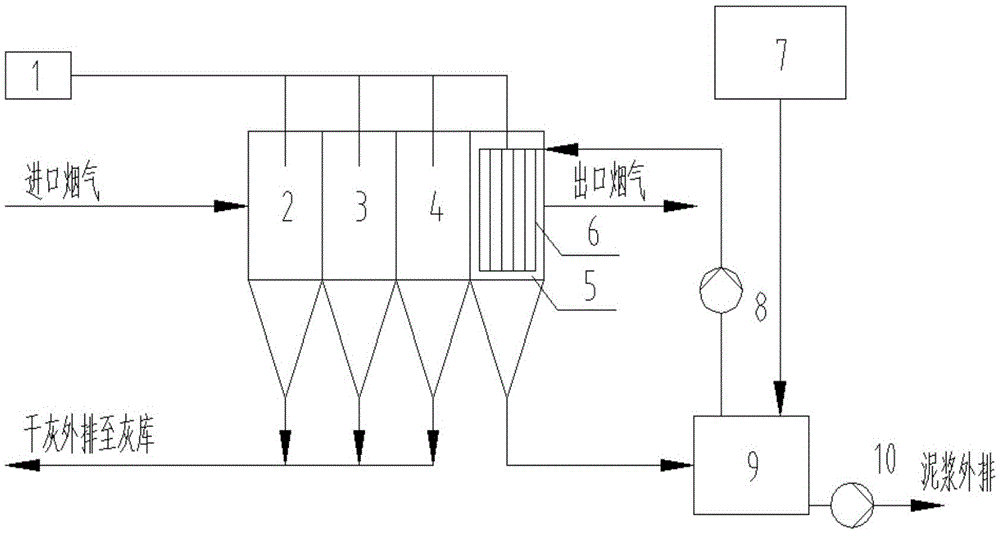

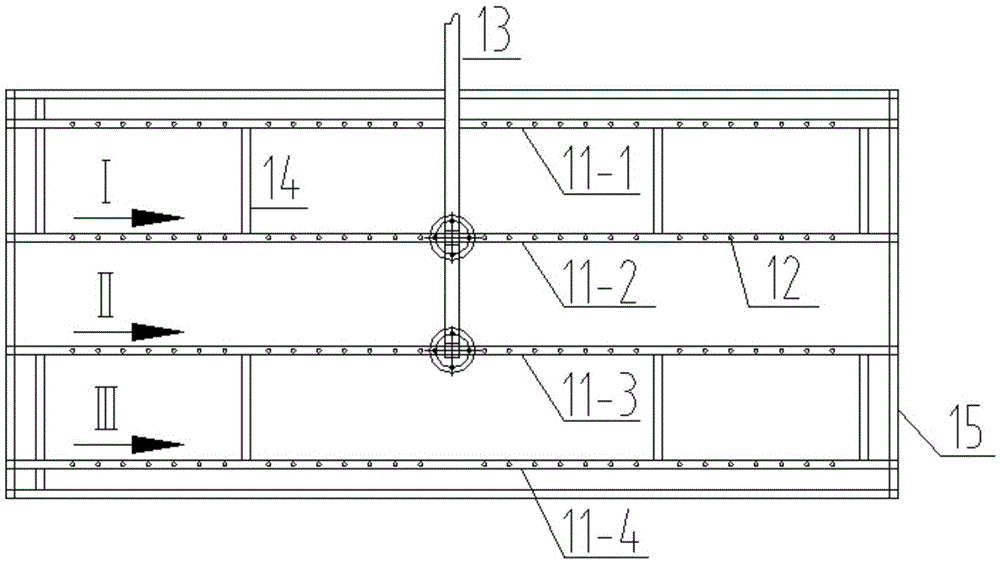

[0033] Taking the 150MW circulating fluidized bed coal-fired power generation unit as an example, the flue gas desulfurization process is furnace desulfurization. The original dust removal system uses a 4-field electrostatic precipitator. The inlet flue gas temperature of the dust collector is 120°C, and the inlet particle concentration is 6600mg / m 3 , outlet particle concentration 20mg / m 3 , the dust collector plate of the fourth electric field is now replaced with a wet flexible plate 6, while the first electric field 2, the second electric field 3, the third electric field 4, the fourth electric field 5, the DC high voltage power supply 1 and the shell of the dust collector are all remain unchanged, as in figure 1 and 2 shown. The supernatant produced by the horizontal cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com