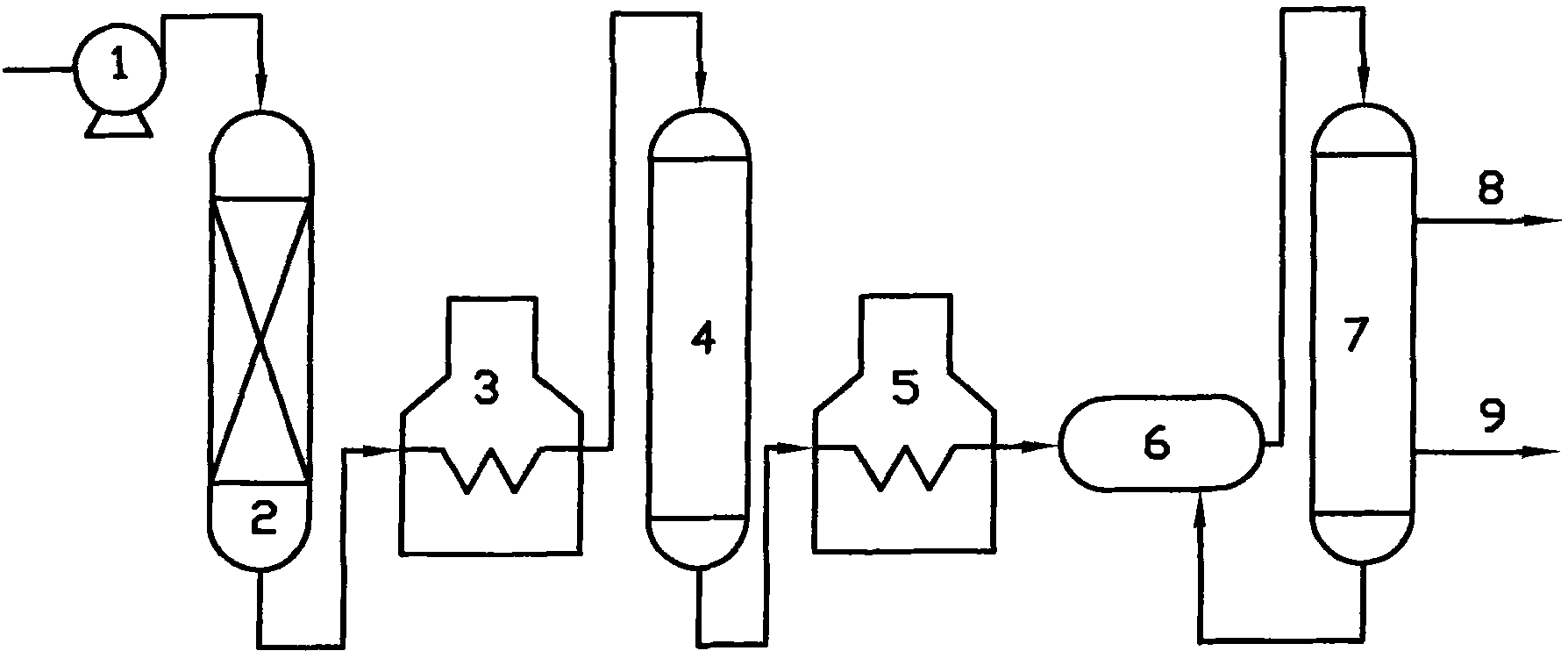

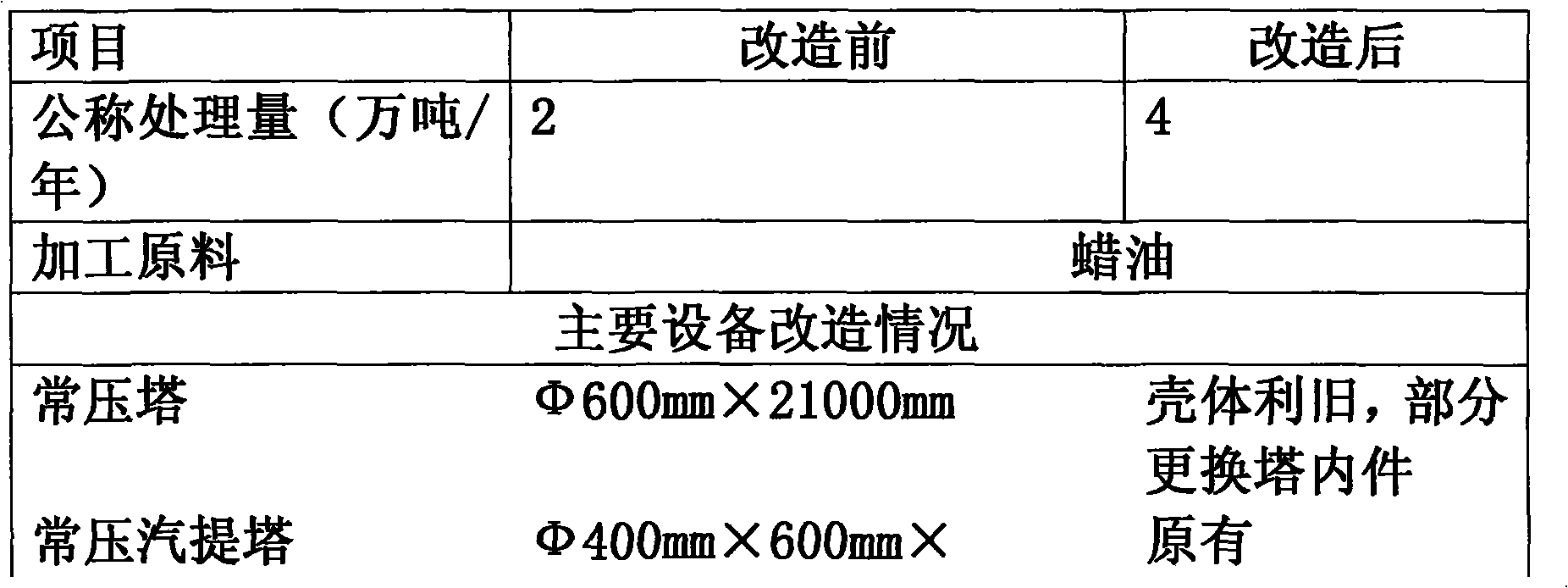

Non-hydrogen dewaxing depressurizing distillation process and device

A distillation device, non-hydrogen technology, applied in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems of low flash point of oil products, poor separation effect of lubricating base oil products, etc., and achieves short downtime, The operation flexibility is large and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

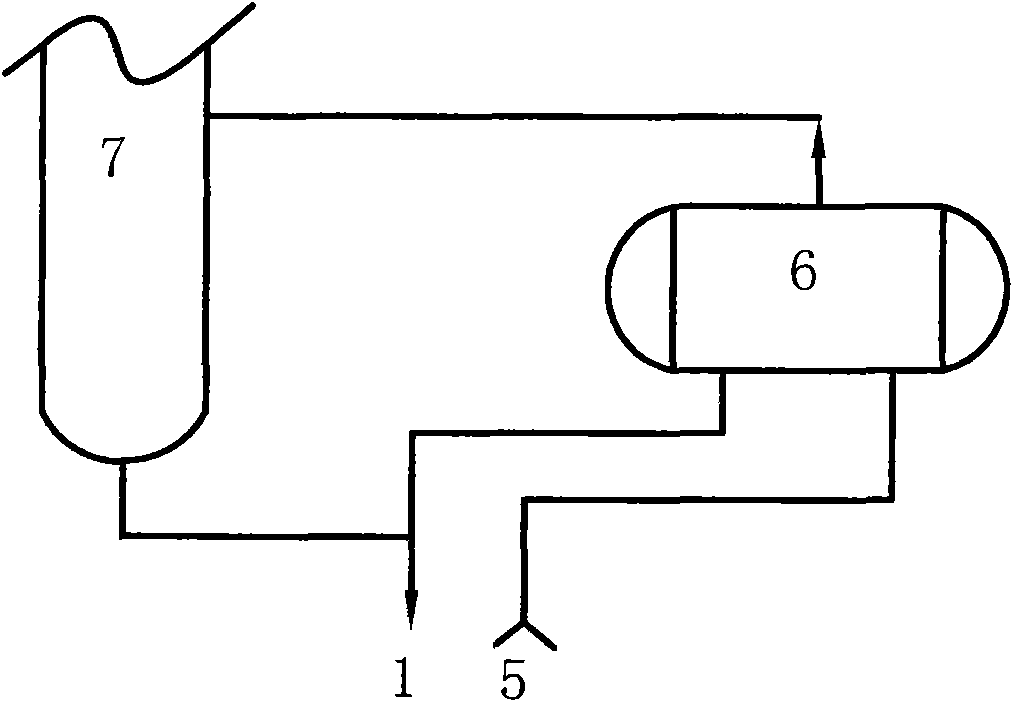

[0026] The wax oil feed rate is 2.54 tons / hour, the outlet temperature of the decompression furnace 5 is 401°C, the pressure of the decompression tower 7 is -0.087MPa, the flash point of the lubricating oil base oil minus the first line 8 is 138°C, and the flash point of the lubricating oil base oil of the minus second line 9: 140°C.

[0027] This example is the typical production data before transformation

Embodiment 2

[0029] The wax oil feed rate is 2.88 tons / hour, the outlet temperature of the decompression furnace 5 is 395°C, the pressure of the decompression tower 7 is -0.087MPa, the flash point of the product minus the first line 8 lubricating oil base oil is 152°C, and the flash point of the product minus the second line 9 lubricating oil base oil The point is: 197°C

[0030] This example is the typical production data after transformation

Embodiment 3

[0032] The wax oil feed rate is 3.45 tons / hour, the outlet temperature of the decompression furnace 5 is 395°C, the pressure of the decompression tower 7 is -0.087MPa, the flash point of the product minus the first line 8 lubricating oil base oil is 182°C, and the flash point of the product minus the second line 9 lubricating oil base oil The point is: 221°C

[0033] This example is the typical production data after transformation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com