A room temperature magnetostrictive material and preparation method thereof

A magnetostrictive material and magnetostrictive technology, applied in the field of functional materials, can solve the problems of low magnetic order temperature, corundum tube rupture, volume expansion, etc., and achieve the effect of increasing the magnetostrictive value and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

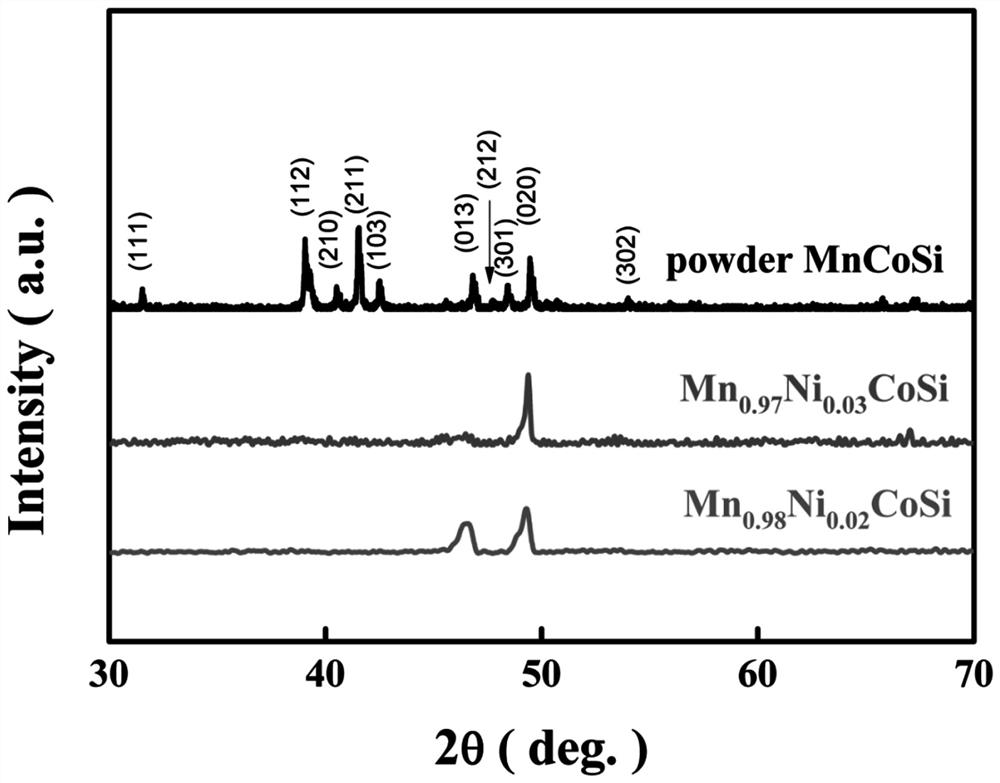

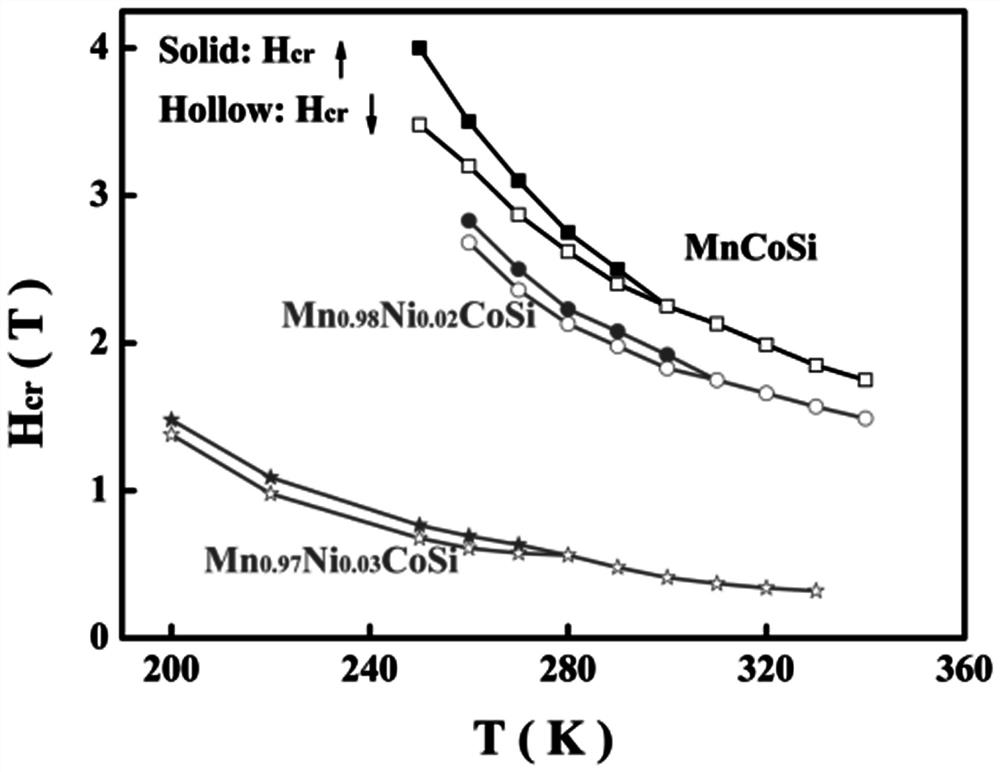

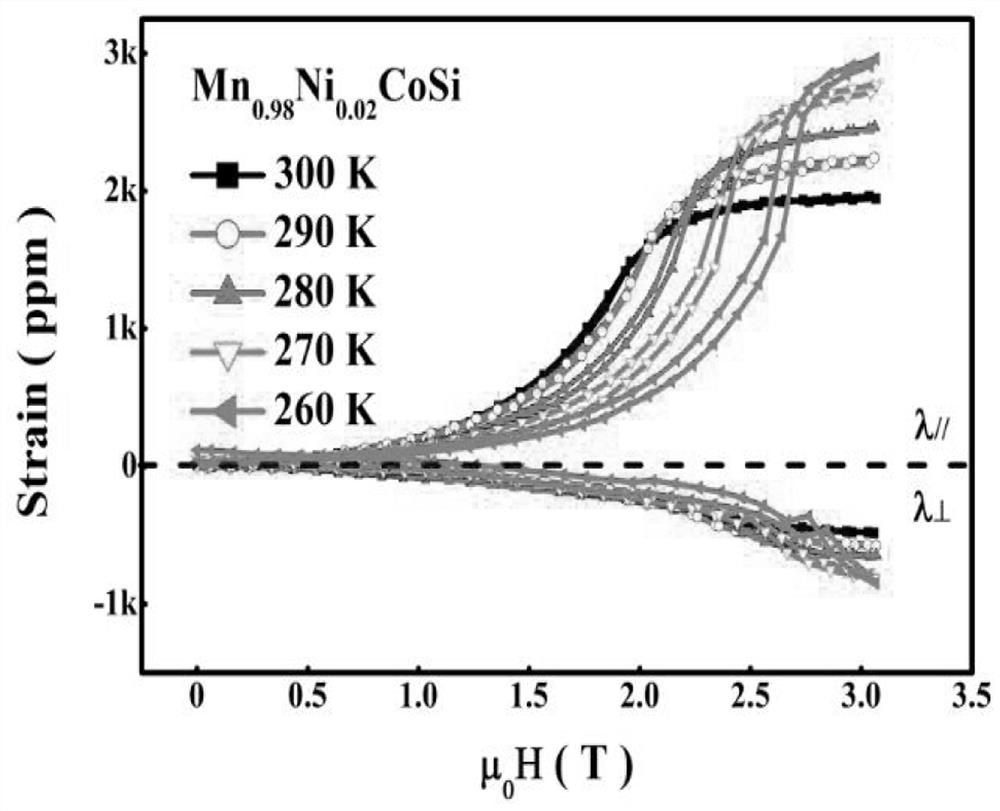

Image

Examples

Embodiment 1

[0040] A preparation method of a room temperature magnetostrictive material, comprising the following steps:

[0041] Step 1. Weigh the raw materials according to the stoichiometric ratio Mn:Ni:Co:Si=0.98:0.02:1:1, mix them evenly, pour the prepared raw materials into a beaker, and add an appropriate amount of concentrated hydrochloric acid. Add clean water and concentrated hydrochloric acid in a ratio of 3:1 and mix, stir for about 15 minutes, clean the oxides on the surface of the raw material, pour off the cleaning solution, add distilled water to clean the raw material again, and pour off the distilled water.

[0042] Step 2: Pour the raw materials into the copper crucible of the electric arc melting furnace. Put the elemental Zr into the copper crucible, number them sequentially, and close the furnace chamber. The electric arc furnace is cooled by a circulating water cooling system. Before smelting, use a mechanical pump to evacuate to below 9Pa, and then use a molecula...

Embodiment 2

[0047] Step 1. Weigh the raw materials according to the stoichiometric ratio Mn:Ni:Co:Si=0.97:0.03:1:1, mix them evenly, pour the prepared raw materials into a beaker, and add an appropriate amount of concentrated hydrochloric acid. Add clean water and concentrated hydrochloric acid in a ratio of 3:1 and mix, stir for about 15 minutes, clean the oxides on the surface of the raw material, pour off the cleaning solution, add distilled water to clean the raw material again, and pour off the distilled water.

[0048] Step 2: Pour the raw materials into the copper crucible of the electric arc melting furnace. Put the elemental Zr into the copper crucible, number them sequentially, and close the furnace chamber. The electric arc furnace is cooled by a circulating water cooling system. Before smelting, use a mechanical pump to evacuate to below 9Pa, and then use a molecular pump to continue evacuating to 5×10 -5 Pa, turn off the molecular pump, fill with argon to 0.6 atmosphere. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetostriction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com