Anti-sticking glaze for hot-bending pressing molding of 3D touch control glass

A glass and anti-adhesion technology, which is applied in the fields of scratch resistance, anti-adhesion, high acid-resistant glaze, and high adhesion. It can solve the problems of manual wiping, equipment, personnel, material waste, and poor ink adhesion. To achieve the effect of weather resistance, safe and non-shedding, reduce use damage, and good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

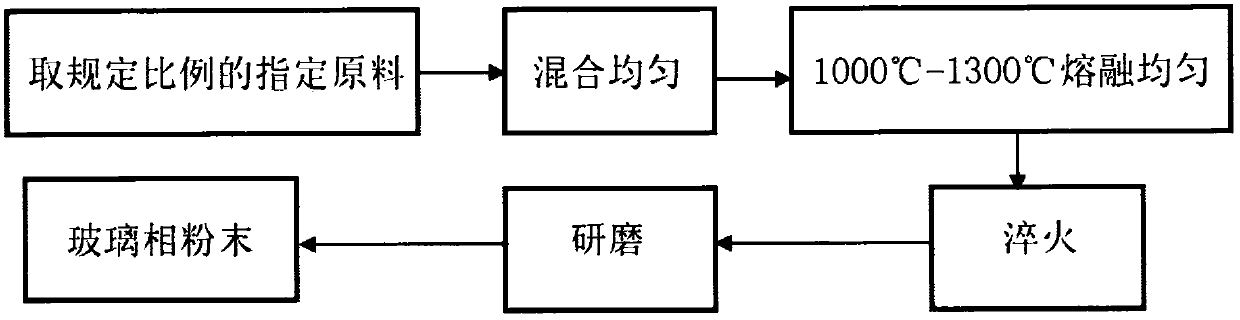

[0028] Such as figure 1 As shown, according to a certain proportion of silicon dioxide SiO 2 (20%-30%); bismuth oxide Bi 2 o 3 (4%-60%); Zinc Oxide ZnO (10%-60%); Sodium Carbonate NaCO3 (10%-15%); titanium oxide TiO 2 (1%--10%); Zirconia ZrO 2 (1%--20%); aluminum oxide Al 2 o 3 (2%--15%); vanadium oxide V 2 o 5 (1%-10%); lithium oxide Li 2 O (1%-10%); boron oxide B 2 o 3 (5%-20%); Potassium Chloride KCl (5%-15%); Calcium Oxide CaO (1-10%); Mix the above raw materials evenly; melt the mixture at a high temperature of 1000°C-1300°C; After that, it is poured into water and quenched to form glass beads; then the glass beads are ball-milled into powder to prepare glass phase powder.

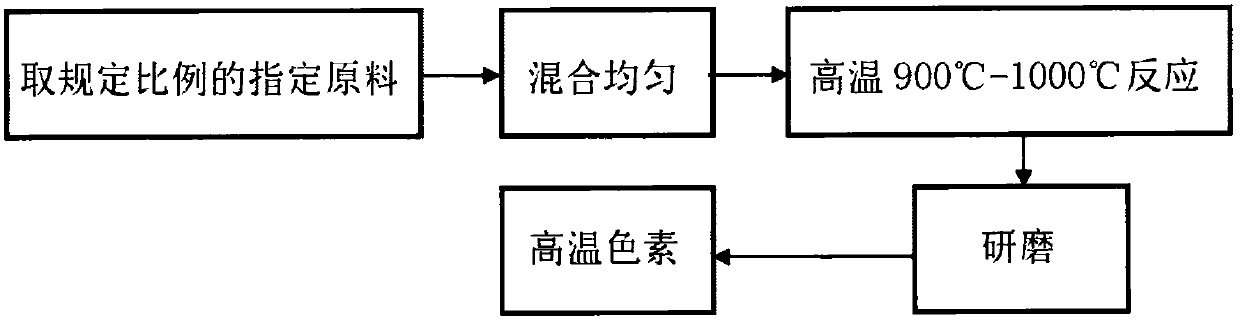

[0029] Such as figure 2 As shown, according to a certain proportion of chromium oxide Cr 2 o 3 (10%-40%); copper oxide CuO (10%-40%); iron oxide FeO (10%-30%); manganese oxide MnO 2 (10%-30%); titanium dioxide (10%-80%); cobalt oxide Co 2 o 3 (5-20%), nickel oxide NiO (5-20%). Thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com