Preparation method of large size MAX phase ceramic impeller

A large-scale, impeller technology, applied in the field of material preparation, can solve the problems of structural material use requirements, reduced LBE corrosion resistance, reduced mechanical properties, etc., and achieves the effect of meeting service requirements and eliminating bubble inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

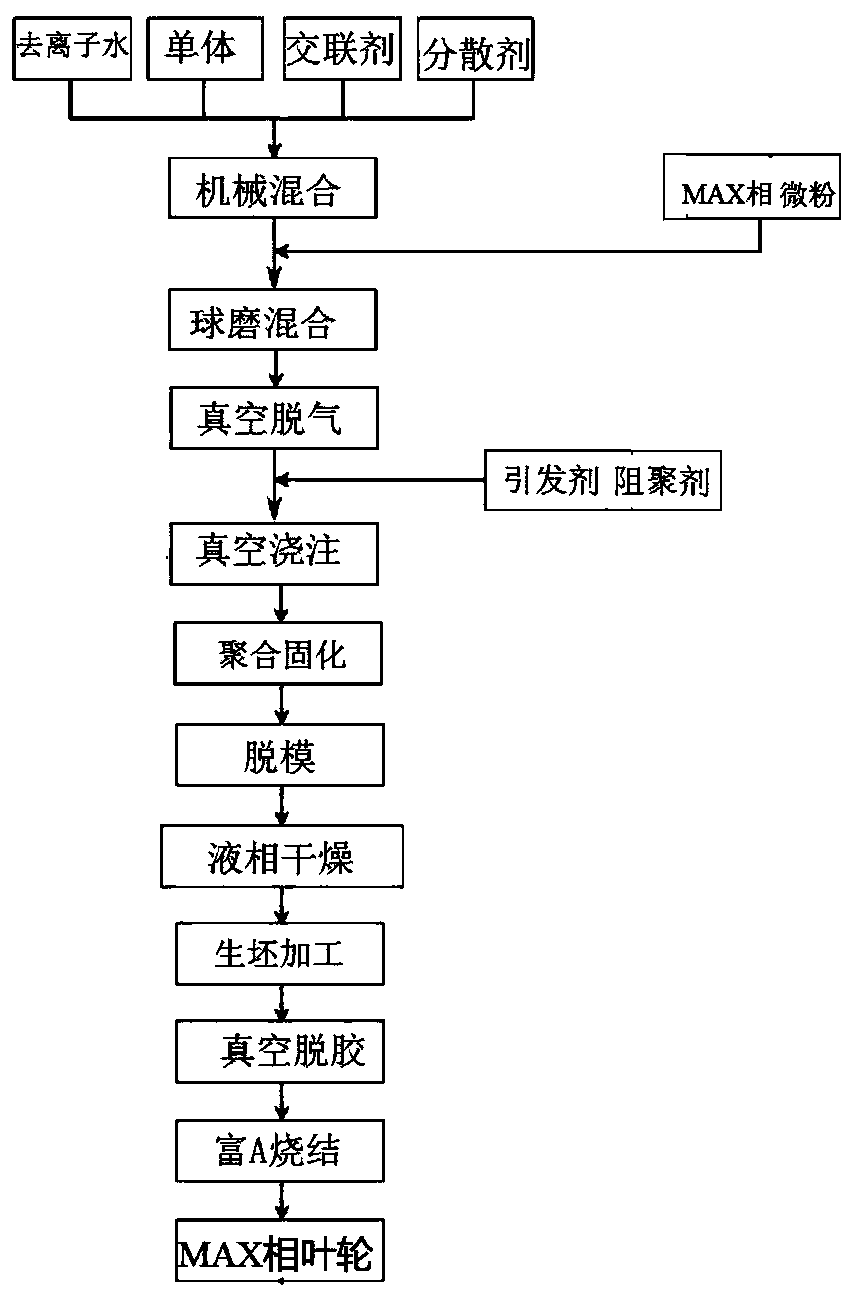

[0049] Such as figure 1 Shown, a kind of large-scale MAX phase ceramic impeller preparation method, its specific steps are as follows:

[0050] (1) Preparation of Ti by combustion synthesis method 3 SiC 2 Micropowder;

[0051] (2) Add monomers, crosslinking agents, dispersants, and defoamers into deionized water to form a premix;

[0052] (3) the Ti described in step (1) 3 SiC 2 The micropowder is added to the premix described in step (2), and mixed by ball milling to obtain an injection molding slurry;

[0053] (4) placing the injection molding slurry described in step (3) in a vacuum environment to remove air bubbles mixed in the slurry;

[0054] (5) Initiator, polymerization inhibitor, catalyst are added in the slurry after removing bubble described in step (4), stir;

[0055] (6) Pouring the slurry described in step (5) into the impeller mold in a vacuum environment, and maintaining the negative pressure until the slurry boils, and discharging the entrained air bubb...

Embodiment 2

[0084] Such as figure 1 Shown, a kind of large-scale MAX phase ceramic impeller preparation method, its specific steps are as follows:

[0085] (1) Preparation of Ti by combustion synthesis method 3 AlC 2 Micropowder;

[0086] (2) Add monomers, crosslinking agents, dispersants, and defoamers into deionized water to form a premix;

[0087] (3) the Ti described in step (1) 3 AlC 2 The micropowder is added to the premix described in step (2), and mixed by ball milling to obtain an injection molding slurry;

[0088] (4) placing the injection molding slurry described in step (3) in a vacuum environment to remove air bubbles mixed in the slurry;

[0089] (5) Initiator, polymerization inhibitor are added in the slurry after removing bubble described in step (4), stir;

[0090] (6) Pouring the slurry described in step (5) into the impeller mold in a vacuum environment, and maintaining the negative pressure until the slurry boils, and discharging the entrained air bubbles. After t...

Embodiment 3

[0118] Such as figure 1 Shown, a kind of large-scale MAX phase ceramic impeller preparation method, its specific steps are as follows:

[0119] (1) Preparation of Ti by combustion synthesis method 2 AlC powder;

[0120] (2) Add monomers, crosslinking agents, dispersants, and defoamers into deionized water to form a premix;

[0121] (3) the Ti described in step (1) 2 AlC micropowder is added in the premix described in step (2), and the ball mill is mixed evenly to obtain the injection molding slurry;

[0122] (4) placing the injection molding slurry described in step (3) in a vacuum environment to remove air bubbles mixed in the slurry;

[0123] (5) Initiator, polymerization inhibitor are added in the slurry after removing bubble described in step (4), stir;

[0124] (6) Pouring the slurry described in step (5) into the impeller mold in a vacuum environment, and maintaining the negative pressure until the slurry boils, and discharging the entrained air bubbles. After the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com