A cationic polyester blended fabric with antibacterial function and its preparation process

A technology of cationic polyester and blended fabrics, applied in textiles, papermaking, knitting, plant fibers, etc., can solve the problems of small surface friction coefficient of chitosan fibers, poor mechanical properties of chitosan fibers, and poor bobbin forming effect, etc. , to achieve bright colors, improve wearability, and reduce the number of hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of preparation technology of cationic polyester blended fabric with antibacterial function, its specific steps are as follows:

[0052] (1) Preparation of cationic polyester raw slivers:

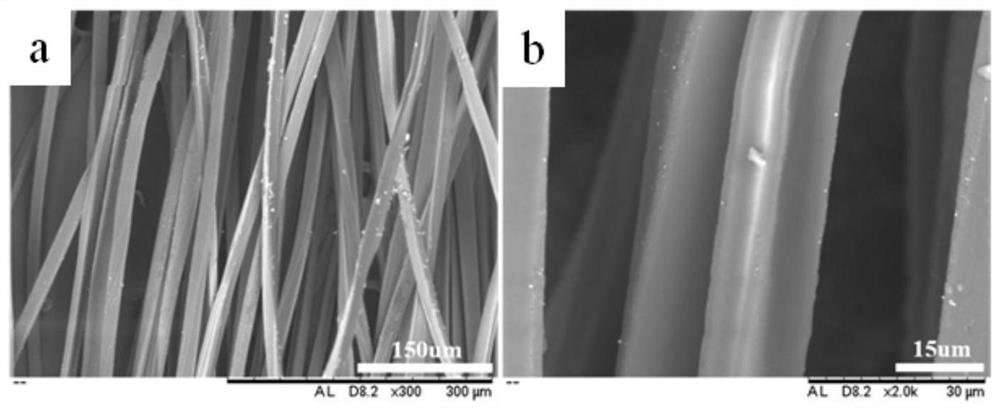

[0053] (1.1) carry out modification treatment to polyester fiber, adopt dimethyl isophthalate-5-sodium sulfonate (SIPM) and polyester copolymerization, obtain cationic polyester fiber;

[0054] (1.2) First of all, if image 3 The cationic polyester shown is soaked in absolute ethanol, and fully washed in an ultrasonic cleaner for 60 minutes, rinsed with deionized water and dried in an oven at 60°C, then spread the cationic polyester on the wire mesh, and then place it In the plasma processing chamber, the output power of the plasma machine power supply and the pressure of the vacuum chamber were adjusted to 150w and 10Pa respectively, and argon gas was passed through for 40s. Finally, the cationic polyester was washed with deionized water for several times and placed in 60 ℃ ...

Embodiment 2

[0074] A kind of preparation technology of cationic polyester blended fabric with antibacterial function, its specific steps are as follows:

[0075] (1) Preparation of cationic polyester raw slivers:

[0076] (1.1) carry out modification treatment to polyester fiber, adopt dimethyl isophthalate-5-sodium sulfonate (SIPM) and polyester copolymerization, obtain cationic polyester fiber;

[0077] (1.2) First, immerse the cationic polyester in absolute ethanol, and fully wash it in an ultrasonic scrubber for 20 minutes, rinse it with deionized water and dry it in an oven at 60°C, then spread the cationic polyester flat on the steel wire mesh, and then It is placed in the plasma processing chamber, and then the output power of the plasma machine power supply and the pressure of the vacuum chamber are adjusted to 200w and 20Pa respectively, and nitrogen is passed through for 100s. Finally, the cationic polyester is washed with deionized water several times and placed in the Dry in ...

Embodiment 3

[0097] A kind of preparation technology of cationic polyester blended fabric with antibacterial function, its specific steps are as follows:

[0098] (1) Preparation of cationic polyester raw slivers:

[0099] (1.1) carry out modification treatment to polyester fiber, adopt dimethyl isophthalate-5-sodium sulfonate (SIPM) and polyester copolymerization, obtain cationic polyester fiber;

[0100] (1.2) First, immerse the cationic polyester in absolute ethanol, and fully wash it in an ultrasonic scrubber for 40 minutes, rinse it with deionized water and dry it in an oven at 60°C, then lay the cationic polyester flat on the steel wire mesh, and then It is placed in the plasma treatment chamber, and then the output power of the plasma machine power supply and the pressure of the vacuum chamber are adjusted to 150w and 15Pa respectively, and oxygen is passed through for 100s. Finally, the cationic polyester is washed with deionized water for several times and placed in the Dry in an...

PUM

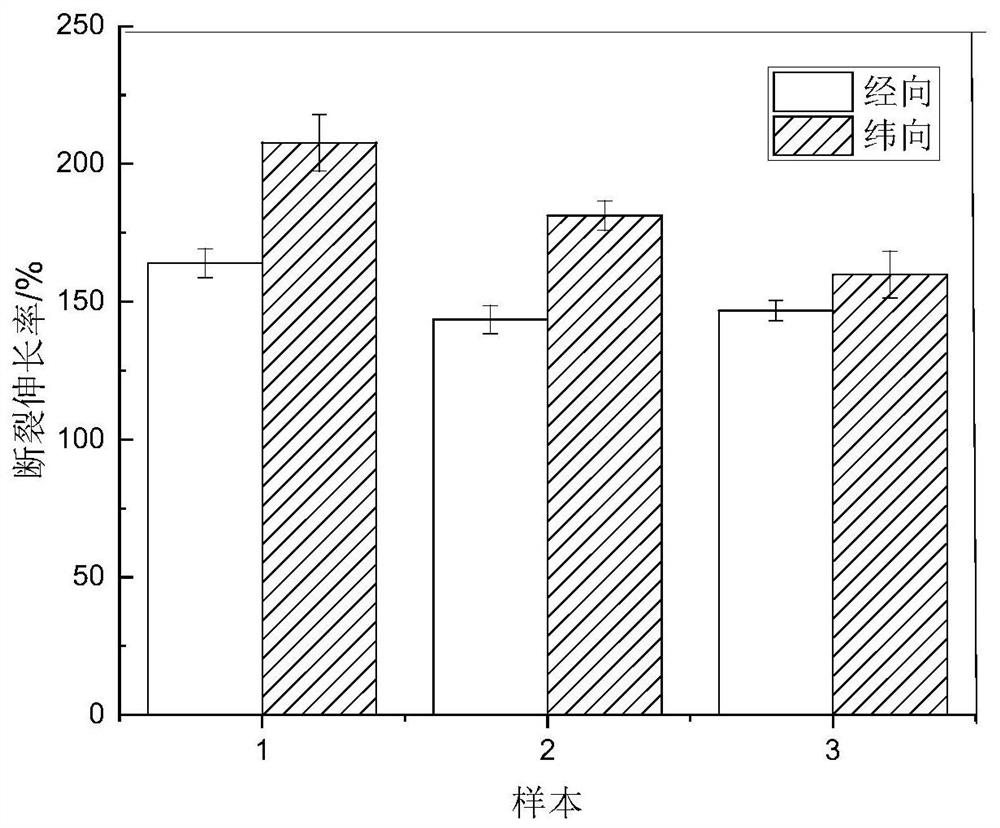

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com