Fingerprint-resistance layer used for goods shelf and preparing method

A fingerprint-resistant and shelf-resistant technology, applied to coatings, devices for coating liquid on surfaces, and special surfaces, can solve problems such as high production costs and difficult subsequent processing of galvanized steel, so as to improve weather resistance and market competition Force, solve the effect of fingerprints remaining on the shelf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

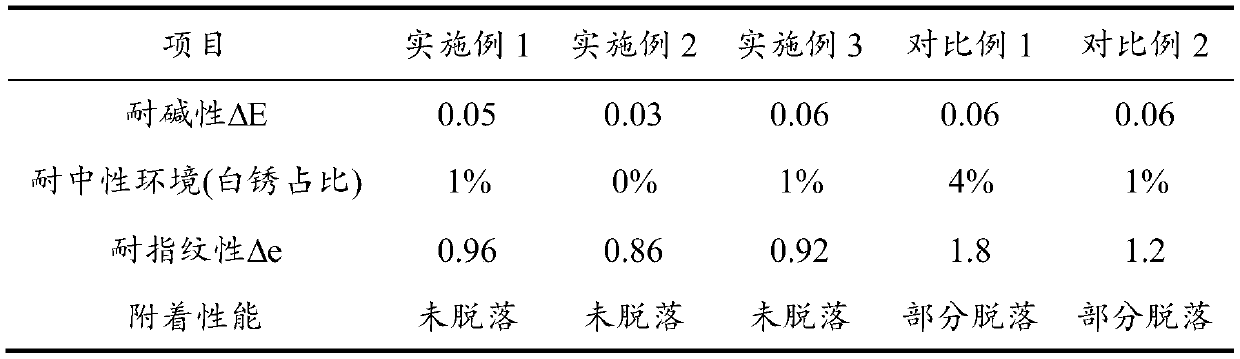

Examples

Embodiment 1

[0024] Anti-fingerprint paint, calculated in parts by weight, the medicament mainly includes 25 parts by weight of acrylic resin emulsion with a solid content of 35%, 20 parts by weight of MS modified silane body (silane glue), 35 parts by weight of deionized water, 10 parts by weight of ethylene glycol Alcohol butyl ether, 10 parts by weight of mixed wax pulp, the weight ratio is polyamide wax pulp: polyethylene wax pulp = 1:2.

[0025] The preparation method of described acrylic resin emulsion is as follows:

[0026] Add 50g of deionized water into a 300ml reaction kettle, then add 5g of polysorbate emulsifier, stir for 3min, and heat up to 60°C.

[0027] In an open container, mix 12g H-perfluorooctyltriethoxysilane, 10g ethyl orthosilicate, 8g acrylic acid, 8g butyl acrylate, and 8g hydroxyethyl acrylate to form acrylic acid monomer mixture, drop by drop Add it into the reaction kettle and heat the reaction kettle to 75°C, keep it warm for 1h, and discharge.

[0028] Unde...

Embodiment 2

[0032] Anti-fingerprint paint, calculated in parts by weight, mainly includes 30 parts by weight of acrylic resin emulsion, 19 parts by weight of MS modified silane body, 35 parts by weight of deionized water, 8 parts by weight of ethylene glycol butyl ether, and 8 parts by weight of mixed type Wax pulp, the weight ratio is polyamide wax pulp: polyethylene wax pulp = 1:1.

[0033] Described acrylic resin emulsion (solid content 40%), its preparation method is as follows:

[0034] Add 60g of deionized water into a 300ml reaction kettle, then add 5g of polysorbate emulsifier, stir for 3min, and heat up to 65°C.

[0035] Mix 10g H-perfluorooctyltriethoxysilane, 12g ethyl orthosilicate, 6g acrylic acid, 6g butyl acrylate, and 6g hydroxyethyl acrylate in an open container to form an acrylic monomer mixture, drop by drop Add to the reaction kettle.

[0036] Heat the reaction kettle to 75°C, keep it warm for 1h, and discharge.

[0037] Under the condition of stirring, deionized wa...

Embodiment 3

[0041] Anti-fingerprint paint, calculated according to parts by weight, the medicament mainly includes 35 parts by weight of acrylic resin emulsion, 15 parts by weight of MS modified silane body (silane glue), 40 parts by weight of deionized water, 5 parts by weight of ethylene glycol butyl ether, 5 parts by weight Parts by weight of mixed wax pulp, the weight ratio is polyamide wax pulp:polyethylene wax pulp=2:1. The medicament used in the patent of the present invention mainly includes.

[0042] Acrylic resin emulsion (solid content 40%), its preparation method is as follows:

[0043] Add 50g of deionized water into a 300ml reaction kettle, then add 6g of polysorbate emulsifier, stir for 3min, and raise the temperature to 60°C.

[0044] In an open container, mix 12g H-perfluorooctyltriethoxysilane, 11g ethyl orthosilicate, 10g acrylic acid, 10g butyl acrylate, and 10g hydroxyethyl acrylate to form acrylic acid monomer mixture, drop by drop Add to the reaction kettle.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com