A kind of cobalt phosphonate and its preparation method and its application as a wide temperature range proton conducting material

A technology of cobalt phosphonate and hydrothermal reaction, applied in the preparation of cobalt phosphonate, the application of cobalt phosphonate as a proton conduction material in a wide working temperature range, in the field of proton conduction materials, can solve the problem of not fully understanding the conductivity and other problems, to achieve the effect of good coordination mode, low cost, excellent water stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

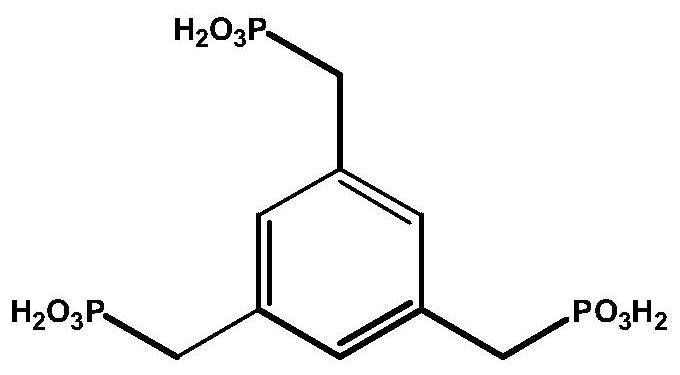

[0047] A kind of cobalt phosphonate, its preparation method comprises: with 0.72g H 6 bmt, 0.46g 4,4'-bipyridine and 0.6g Co(OAc) 2 4H 2 O was added to 30 mL of deionized water, stirred and 60 μL of 1 mol / L NaOH solution was added. Then place it in an autoclave at 100° C. for 48 hours at a constant temperature, and after cooling to room temperature, crystals are precipitated, and the crystals are washed with deionized water several times to obtain cobalt phosphonate. The cobalt phosphonate is a pink blocky crystal. Elemental analysis data C 48 h 78 co 2 N 6 o 32 P 6 , Theoretical: C, 37.08; H, 5.06; N, 5.41%. Found: C, 37.46; H, 5.42; N, 5.04%. Main infrared data (KBr, cm -1 ): 3379, 3098, 3056, 2911, 1611, 1521, 1453, 1237, 1151, 1020, 934.

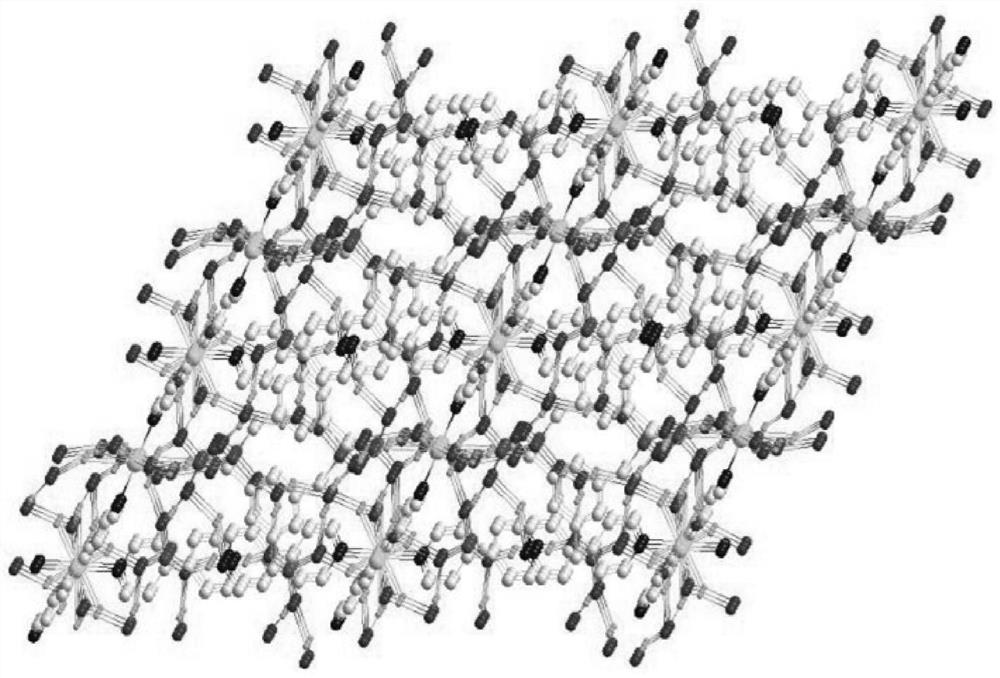

[0048] Analyze the single crystal structure of the cobalt phosphonate prepared in Example 1 of the present invention, collect the single crystal diffraction data with a Bruker Smart CCD diffractometer, and use a graphite mono...

Embodiment 2

[0050] A kind of cobalt phosphonate, its preparation method comprises: with 0.72g H 6 bmt, 0.46g 4,4'-bipyridine and 0.6g Co(OAc) 2 4H 2 O was added to 30 mL of deionized water, stirred and 60 μL of 1 mol / L NaOH solution was added. Then place it in an autoclave at 140° C. for 72 hours at a constant temperature, and after cooling down to room temperature, crystals are precipitated, and the crystals are washed with deionized water several times to obtain cobalt phosphonate. The cobalt phosphonate is a pink blocky crystal.

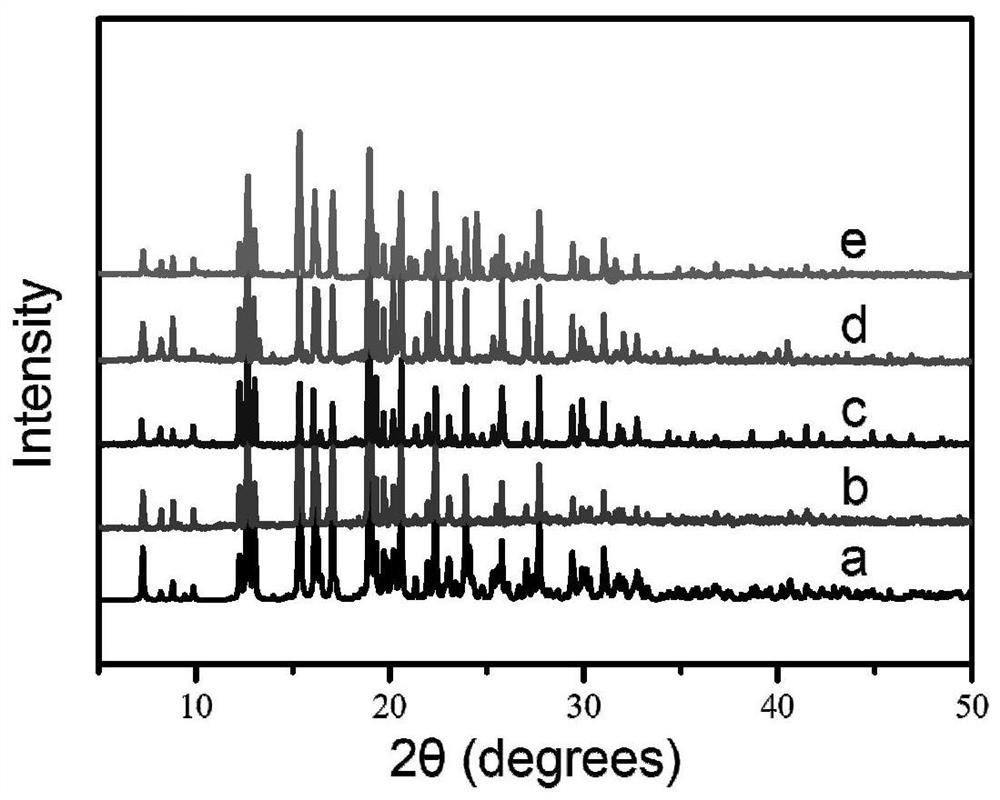

[0051] The cobalt phosphonate prepared in Example 2 of the present invention was analyzed by X-ray diffraction, and its diffraction peaks were consistent with the simulated diffraction peaks obtained by single crystal analysis in Example 1 of the invention, illustrating the preparation according to Example 1 and Example 2 The method obtained is the same substance.

[0052] In order to investigate the proton conductivity of the cobalt phosphonate prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com