Anti-reduction BaTiO3-based dielectric ceramic and preparation method thereof

A dielectric ceramic, batio3-xbi technology, which is applied in the field of anti-reduction BaTiO3-based dielectric ceramics and its preparation, can solve the problems of complex system material composition, poor temperature stability at high temperature end, unable to meet the requirements of 150 ℃, etc., and achieve excellent insulation performance. , High temperature stability, the effect of improving insulation resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

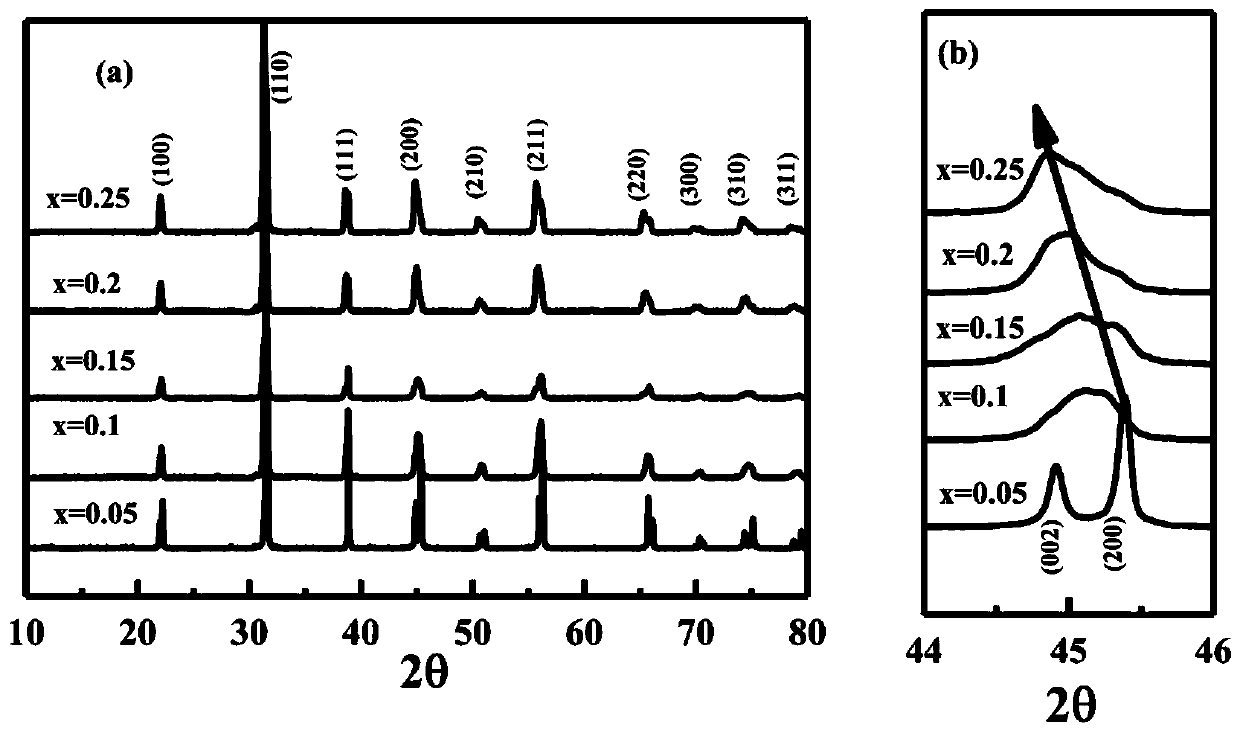

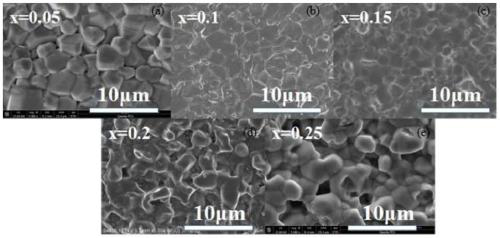

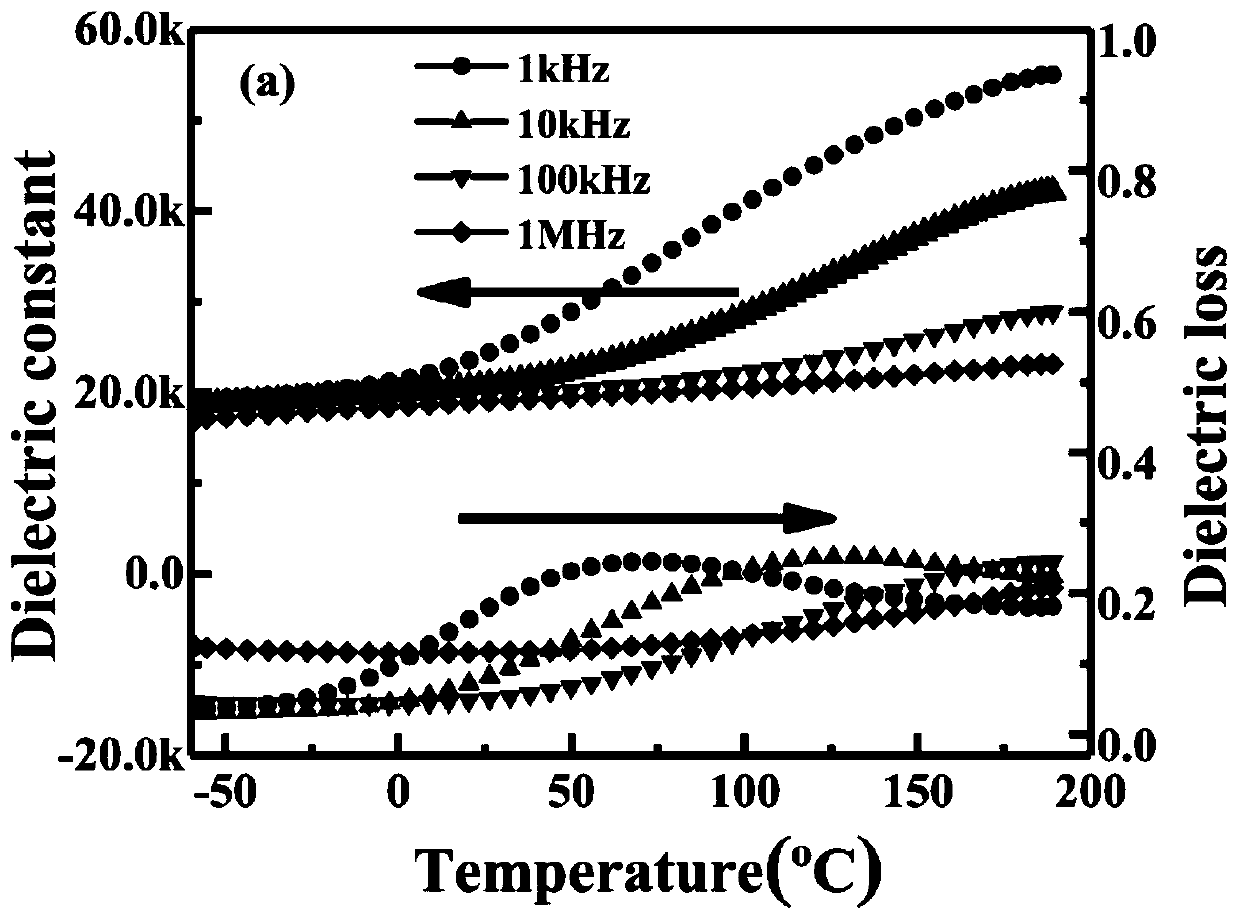

[0036] a BaTiO 3 Base dielectric ceramic, the chemical composition expression is 0.95BaTiO 3 -0.05Bi(Zn 1 / 2 Y 1 / 2 )O 2.75 , its preparation method specifically comprises the following steps:

[0037] (1) According to the composition expression, weigh 0.95mol BaTiO 3 , 0.0263mol Bi 2 O 3 (5% excess), 0.025mol ZnO and 0.0125mol Y 2 O 3 as a raw material;

[0038] (2) Put the weighed raw materials into a ball mill jar, use zirconia balls and absolute ethanol as a medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and then pre-burn them. The pre-burning process is as follows: Raise the temperature from room temperature to 850°C at a heating rate of 2°C / min, keep it warm for 2 hours, and then cool with the furnace; mill the pre-fired powder for a second time for 6 hours, and dry it at 100°C to obtain ceramic powder;

[0039] (3) in the ceramic powder of step (2) gained, add the polyvinyl alcohol aqueous solution that concentrat...

Embodiment 2

[0046] a BaTiO 3 Base dielectric ceramics, the chemical composition expression is 0.9BaTiO 3 -0.1Bi(Zn 1 / 2 Y 1 / 2 )O 2.75 , its preparation method specifically comprises the following steps:

[0047] (1) According to the composition expression, weigh 0.9mol BaTiO 3 , 0.0525mol Bi 2 O 3 (5% excess), 0.05mol ZnO and 0.025mol Y 2 O 3 as a raw material;

[0048] (2) Put the weighed raw materials into a ball mill jar, use zirconia balls and absolute ethanol as a medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and then pre-burn them. The pre-burning process is as follows: Raise the temperature from room temperature to 850°C at a heating rate of 2°C / min, keep it warm for 2 hours, and then cool with the furnace; mill the pre-fired powder for a second time for 6 hours, and dry it at 100°C to obtain ceramic powder;

[0049] (3) in the ceramic powder of step (2) gained, add the polyvinyl alcohol aqueous solution that concentration ...

Embodiment 3

[0056] a BaTiO 3 Base dielectric ceramics, the chemical composition expression is 0.85BaTiO 3 -0.15Bi(Zn 1 / 2 Y 1 / 2 )O 2.75 , its preparation method specifically comprises the following steps:

[0057] (1) According to the composition expression, weigh 0.85mol BaTiO 3 , 0.0788mol Bi 2 O 3 (5% excess), 0.075mol ZnO and 0.0375mol Y 2 O 3 as a raw material;

[0058] (2) Put the weighed raw materials into a ball mill jar, use zirconia balls and absolute ethanol as a medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and then pre-burn them. The pre-burning process is as follows: Raise the temperature from room temperature to 850°C at a heating rate of 2°C / min, keep it warm for 2 hours, and then cool with the furnace; mill the pre-fired powder for a second time for 6 hours, and dry it at 100°C to obtain ceramic powder;

[0059] (3) in the ceramic powder of step (2) gained, add the polyvinyl alcohol aqueous solution that concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com