Efficient laser continuous handheld welding equipment

A welding equipment and handheld technology, which is applied in the field of high-efficiency laser continuous handheld welding equipment, can solve the problems of inconvenient handling and movement, low number of laser lasers, and large volume, and achieve the effect of easy control of power, easy adjustment of parameters, and large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

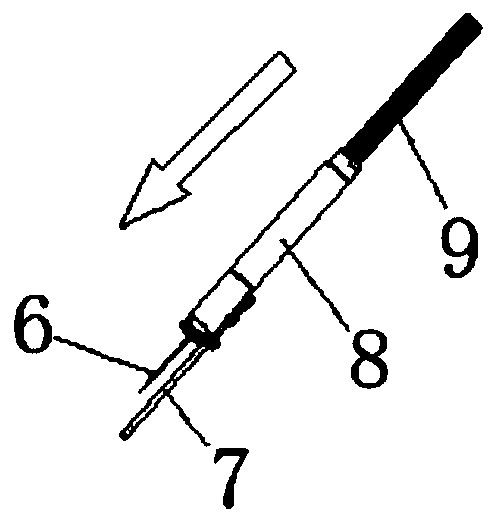

[0029] see Figure 1-4 , in the embodiment of the present invention, a high-efficiency laser continuous handheld welding equipment includes a cabinet 2, a continuous fiber laser 3 is installed inside the cabinet 2, and a circuit control system is installed in the cabinet 2 above the continuous fiber laser 3, The continuous fiber laser 3 is a device that generates high voltage and emits laser light after the circuit is processed. An operation panel 5 is installed on the upper slope of the cabinet 2, and a plurality of optical fiber line placement seats 4 are installed on the top of the cabinet 2. After welding Afterwards, the overlong optical fiber line and laser rod 8 can be placed to prevent damage caused by transportation.

[0030] like figure 2 As shown, it also includes a hand-held laser rod 8 connected to the continuous fiber laser 3, and the connecting wire harness between the laser rod 8 and the continuous fiber laser 3 is provided with a bellows 9 to reduce the wear ...

Embodiment 2

[0032] see figure 1 and 4 , the difference between this embodiment and embodiment 1 is:

[0033] Further, a plurality of casters 1 are installed on the bottom of the cabinet 2 to facilitate the movement and fixation of the device.

[0034] Further, the inner side of the cabinet 2 is also installed with a water cooling device for cooling the continuous fiber laser 3, and the water cooling device is used to cool the temperature generated by the laser to the components to prolong the service life.

[0035] Further, the model of the operation panel 5 is XP3-18T, and the operation panel 5 is designed with a button screen. The operation panel 5 is provided with a power switch, a shutter switch and a man-machine interface, and a laser can be set on the button screen. Parameters, by adjusting the laser parameters to achieve the desired laser process.

[0036] Further, there are at least four optical fiber wire placing seats 4 on the top of the cabinet 2 , and the laser rod 8 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com