A kind of preparation method of pure titanium metallographic sample

A technology of metallographic samples and pure titanium, which is applied in the field of preparation of pure titanium metallographic samples, can solve the problems of difficult elimination of fine scratches and difficult preparation of pure titanium metallographic samples, and achieve high sample preparation efficiency, Convenient organizational structure and easy conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

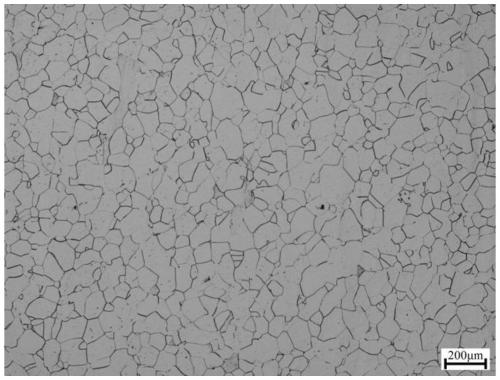

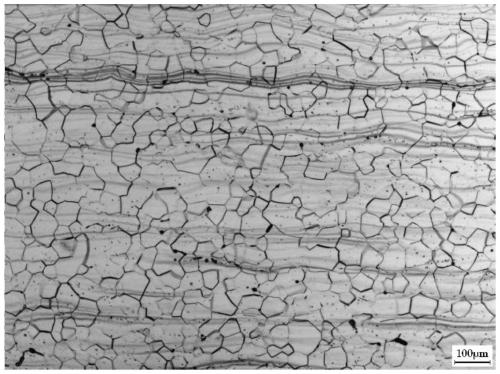

Image

Examples

Embodiment 1

[0025] The preparation method of the pure titanium metallographic sample of the present embodiment comprises the following steps:

[0026] Step 1. Cut a pure titanium sample from the annealed pure titanium part, then perform rough grinding and fine grinding on the water sandpaper in sequence, and keep the water sandpaper wet during the rough grinding and fine grinding;

[0027] Step 2, immerse the pure titanium sample after rough grinding and fine grinding in step 1 in the acidic solution for 20s to carry out passivation treatment, and then clean the pure titanium sample after passivation treatment with water; the acidic solution It is composed of nitric acid solution, hydrochloric acid solution and water with a volume ratio of 1:3:7, the mass fraction of the nitric acid solution is 66%, and the mass fraction of the hydrochloric acid solution is 37%;

[0028] Step 3, polishing the pure titanium sample after cleaning in step 2; the polishing cloth used in the polishing treatmen...

Embodiment 2

[0039] The preparation method of the pure titanium metallographic sample of the present embodiment comprises the following steps:

[0040] Step 1. Cut a pure titanium sample from the annealed pure titanium part, then perform rough grinding and fine grinding on the water sandpaper in sequence, and keep the water sandpaper wet during the rough grinding and fine grinding;

[0041] Step 2, immerse the pure titanium sample after rough grinding and fine grinding in step 1 in an acidic solution for 15s to carry out passivation treatment, and then clean the pure titanium sample after passivation treatment with water; the acidic solution It is composed of nitric acid solution, hydrochloric acid solution and water with a volume ratio of 1:3:5, the mass fraction of the nitric acid solution is 68%, and the mass fraction of the hydrochloric acid solution is 38%;

[0042] Step 3, polishing the pure titanium sample after cleaning in step 2; the polishing cloth used in the polishing treatment...

Embodiment 3

[0045] The preparation method of the pure titanium metallographic sample of the present embodiment comprises the following steps:

[0046] Step 1. Cut the pure titanium sample from the processed hard pure titanium parts, and then perform rough grinding and fine grinding on the water sandpaper in sequence, and keep the water sandpaper wet during the rough grinding and fine grinding process;

[0047] Step 2, immerse the pure titanium sample after rough grinding and fine grinding in step 1 in an acidic solution for 17s to carry out passivation treatment, and then clean the pure titanium sample after passivation treatment with water; The solution is composed of nitric acid solution, hydrochloric acid solution and water with a volume ratio of 2:4:7, the mass fraction of the nitric acid solution is 67%, and the mass fraction of the hydrochloric acid solution is 36%;

[0048] Step 3, polishing the pure titanium sample after cleaning in step 2; the polishing cloth used in the polishin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com