A kind of antibacterial water-based polyurethane adhesive and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of increased volume of antibacterial active ingredients, reduced antibacterial effect, and increased difficulty of antibacterial active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

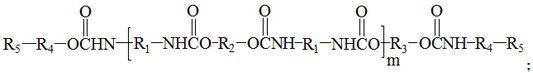

Image

Examples

Embodiment 1

[0029] (1) Add 1 mol of polyoxyethylene ether-50 (PEG-10) and 0.02 mol of 2,2-dimethylolpropionic acid into the reaction kettle, heat up to 120°C, vacuumize to remove moisture, and reach the weight ratio of moisture 0.03%; cool down to 45°C, add 2.02 mol of hexamethylene diisocyanate to the system, and raise the temperature to 100°C, react for 0.5 hours and cool down to 40°C to obtain an isocyanate prepolymer;

[0030] (2) Add 2100g methyl ethyl ketone to the isocyanate prepolymer to reduce the viscosity of the system, then add 2 mol hydroxypropyl methacrylate, raise the temperature to 100°C, react for 2 hours and then cool down to 40°C;

[0031] (3) Dissolve 2 mol of maleimide and 0.1 mol of azobisisobutyronitrile in 450 g of butanone, and slowly add it dropwise to the system prepared in step (2), keep the temperature at 80°C for 0.5 hours, then cool down to 3°C; Slowly add 3200g of 10% bromobutanone solution dropwise, control the dropwise temperature <10°C, raise the tempera...

Embodiment 2

[0035](1) Add 1 mol of polyoxypropylene ether-30 (PPG-30) and 0.1 mol of 2,2-dimethylolpropionic acid into the reaction kettle, heat up to 150°C, vacuumize to remove moisture, and reach the weight ratio of moisture 0.07%; cool down to 40°C, add 2 mol 2,4-toluene diisocyanate to the system, and raise the temperature to 60°C, react for 8 hours and cool down to 40°C to obtain an isocyanate prepolymer;

[0036] (2) Add 2800g methyl ethyl ketone to the isocyanate prepolymer to reduce the viscosity of the system, then add 1.8 mol hydroxypropyl acrylate, heat up to 90°C, react for 7 hours and cool down to 40°C;

[0037] (3) Dissolve 1.8 mol of maleimide and 0.08 mol of azobisisobutyronitrile in 500 g of butanone, and slowly add it dropwise to the system prepared in step (2), keep the temperature at 55°C for 6 hours, then cool down to 0°C; Slowly add 870g of 10% bromobutanone solution dropwise, control the dropwise temperature <10°C, raise the temperature to 25°C, and stir for 2 hours...

Embodiment 3

[0041] (1) Add 1 mol of polyoxyethylene-20-polyoxypropylene-20 copolymer (PEG-20-co-PPG-20) and 0.08 mol of 2,2-dimethylolbutyric acid into the reactor, and heat up to 150 ℃, vacuumize to remove moisture until the weight ratio of moisture is 0.09%; cool down to 50°C, add 1.5 mol diphenylmethane diisocyanate to the system, and raise the temperature to 70°C, react for 3 hours and then cool down to 40°C to obtain isocyanate pre- Polymer;

[0042] (2) Add 2500g methyl ethyl ketone to the isocyanate prepolymer to reduce the viscosity of the system, then add 0.84 mol hydroxyethyl acrylate, raise the temperature to 70°C, and cool down to 40°C after 16 hours of reaction;

[0043] (3) Dissolve 0.84 mol of maleimide and 0.03 mol of azobisisobutyronitrile in 250 g of butanone, and slowly add it dropwise to the system prepared in step (2), keep the temperature at 55°C for 6 hours, then cool down to 0°C; Slowly add 400g of 10% bromobutanone solution dropwise, control the dropwise temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com