A kind of mof-derived clustered cerium-based phosphorus removal adsorbent and preparation method thereof

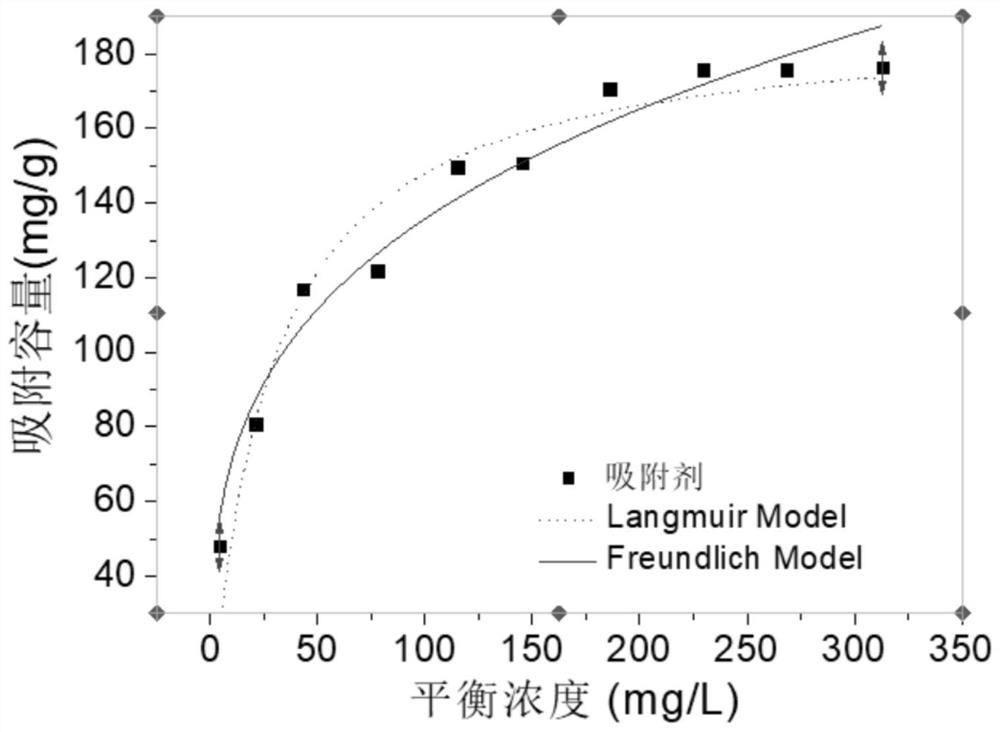

A phosphorus adsorbent and adsorbent technology, applied in the field of water pollution treatment, can solve the problems of low removal efficiency and removal rate, low phosphate sensitivity, uncertain acidity and alkalinity, and achieve good selectivity and sensitivity, excellent Acid-base tolerance, effect of improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

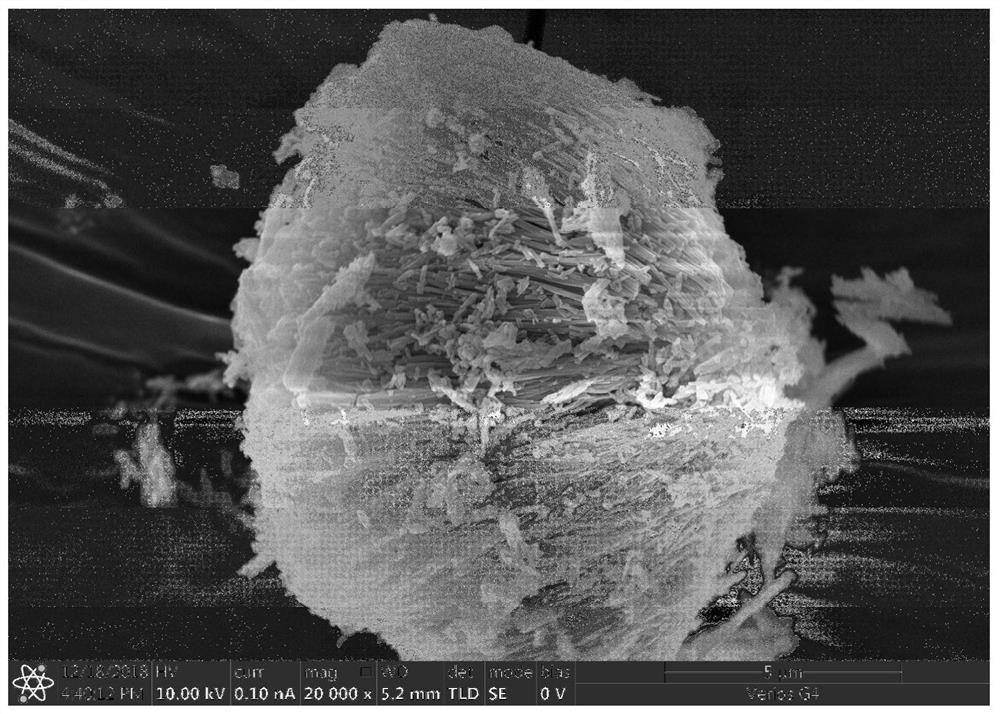

Embodiment 1

[0030] Step 1, press trimesic acid and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O was 1:1 for the experiment. Prepare a solution of trimesic acid with a concentration of 1mol / L and a solution of cerium nitrate with a concentration of 1mol / L; mix the two solutions at a volume ratio of 1:1 to obtain a mixed solution, and place the mixed solution on a shaking table for a shaking reaction for 1.5 hours Afterwards, settle naturally for 0.5h, wash 3 times with deionized water, and then wash 2 times with absolute ethanol, the time of each washing is 5min, the rotation speed of each washing is 5000r / min, and vacuum-dry at 50°C for 7h. Get the adsorbent precursor;

[0031] Step 2: Calcining the adsorbent precursor in a nitrogen atmosphere, the heating rate of the calcination is 10°C / min, the temperature of the calcination is 500°C, and the time is 3h, to obtain the MOF-derived clustered cerium-based phosphorus removal adsorbent.

[0032] In this embodiment, in step 1, the trimesic acid...

Embodiment 2

[0034] Step 1, press trimesic acid and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O was 2:1 for the experiment. Prepare a solution of trimesic acid with a concentration of 1mol / L and a solution of cerium nitrate with a concentration of 1mol / L; mix the two solutions at a volume ratio of 2:1 to obtain a mixed solution, and place the mixed solution on a shaking table for a shaking reaction for 2.5 hours Afterwards, settle naturally for 0.7h, wash 3 times with deionized water, and then wash 2 times with absolute ethanol, the time of each washing is 5min, the rotation speed of each washing is 5000r / min, and vacuum-dry at 50°C for 7h. Get the adsorbent precursor;

[0035] Step 2: Calcining the adsorbent precursor in a nitrogen atmosphere, the heating rate of the calcination is 10°C / min, the calcination temperature is 600°C, and the calcination time is 2.5h to obtain the MOF-derived clustered cerium-based phosphorus removal adsorbent.

[0036] In this embodiment, in step 1, the trimesi...

Embodiment 3

[0038] Step 1, press trimesic acid and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O was 3:1 for the experiment. Prepare a 1mol / L trimesic acid solution and a 1mol / L cerium nitrate solution respectively; mix the two solutions at a volume ratio of 3:1 to obtain a mixed solution, place the mixed solution on a shaker for 3 hours after shaking , naturally settled for 0.9h, washed 3 times with deionized water, and then washed 2 times with absolute ethanol, the time of each washing was 5min, the rotation speed of each washing was 5000r / min, and vacuum-dried at 50°C for 7h to obtain Adsorbent precursors;

[0039]Step 2: Calcining the adsorbent precursor in a nitrogen atmosphere, the heating rate of the calcination is 10°C / min, the temperature of the calcination is 500°C, and the time is 3h, to obtain the MOF-derived clustered cerium-based phosphorus removal adsorbent.

[0040] In this embodiment, in step 1, the trimesic acid solution is obtained by stirring and dissolving trimesic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com