Diaphragm for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and diaphragms, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as complex methods and high costs, achieve good thermal stability, and improve high temperature resistance performance, easy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

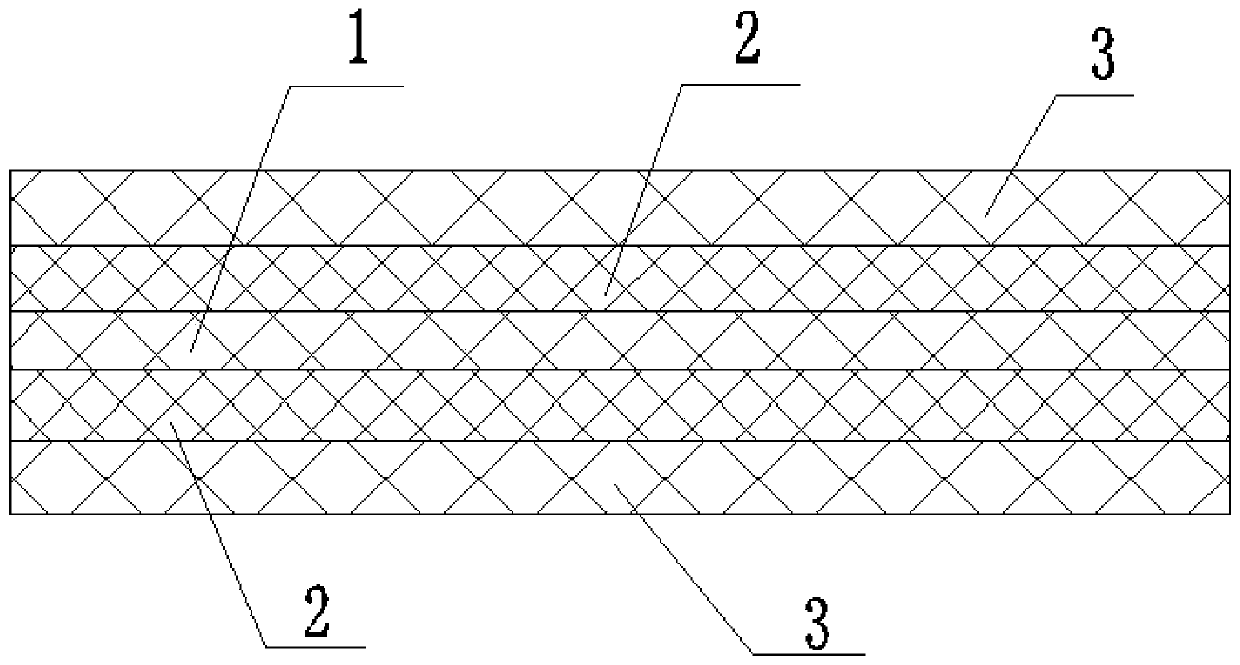

[0027] Such as figure 1 Shown, the preparation method of separator for lithium ion battery of the present invention comprises the following steps,

[0028] 1. Coating the first ceramic layer 1 on one side of the polyethylene base film, the first ceramic layer includes 65% ceramic oxide and 35% adhesive by weight, and the ceramic oxide is aluminum oxide and vanadium oxide The mixture (weight ratio is 1:1), the average particle size is 15nm, the binder is polyvinyl alcohol, and the coating thickness is 0.5-1μm. After completion, it is dried at 70°C for 30-50min.

[0029] 2. After drying, coat the gel polymer layer 2 on the other side of the polyethylene base film and the surface of the first ceramic layer. The gel polymer layer is a mixture of polytetrafluoroethylene and polyacrylonitrile (weight ratio It is an aqueous solution of 2:1), the particle size of polytetrafluoroethylene and polyacrylonitrile is 30-50nm, and the thickness of the coating is 1-2μm. After the coating is ...

Embodiment 2

[0032] The preparation method of separator for lithium ion battery of the present invention comprises the following steps,

[0033] 1. Coating the first ceramic layer on one side of the polyethylene base film, the first ceramic layer includes 75% ceramic oxide and 25% adhesive by weight, and the ceramic oxide is a mixture of alumina and zirconia (The weight ratio is 1:1), the average particle size is 30nm, the binder is sodium carboxymethyl cellulose, and the coating thickness is 0.5-1μm. After completion, dry at 70°C for 30-50min.

[0034]2. After drying, coat the gel polymer layer on the other side of the polyethylene base film and the surface of the first ceramic layer. The gel polymer layer is a mixture of polytetrafluoroethylene and polyacrylonitrile (the weight ratio is 2:1) aqueous solution, the particle size of polytetrafluoroethylene and polyacrylonitrile is 30-50nm, and the thickness of the coating is 1-2μm. After the coating is completed, dry it at about 85°C for 50...

Embodiment 3

[0037] The preparation method of separator for lithium ion battery of the present invention comprises the following steps,

[0038] 1. Coating the first ceramic layer on one side of the polyethylene base film, the first ceramic layer includes 70% ceramic oxide and 30% adhesive by weight, and the ceramic oxide is a mixture of aluminum oxide and vanadium oxide (The weight ratio is 1:1), the average particle size is 20nm, the binder is polyvinyl alcohol, and the coating thickness is 0.5-1μm. After completion, dry at 70°C for 30-50min.

[0039] 2. After drying, coat the gel polymer layer on the other side of the polyethylene base film and the surface of the first ceramic layer. The gel polymer layer is a mixture of polyimide and aramid resin (the weight ratio is 1:1) aqueous solution, the particle size of polyimide and aramid resin is 30-50nm, and the coating thickness is 1-2μm. After coating, dry at about 90°C for 50-80min.

[0040] 3. After drying, coat the third ceramic layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com