A miniature current heating rapid annealing furnace and heating fixture

A heating fixture and annealing furnace technology, applied in electric furnace heating, lighting and heating equipment, furnaces and other directions, can solve the problems of slow heating, large volume and high energy consumption of annealing furnaces, achieve rapid heating, high flexibility, and improve thermal energy utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

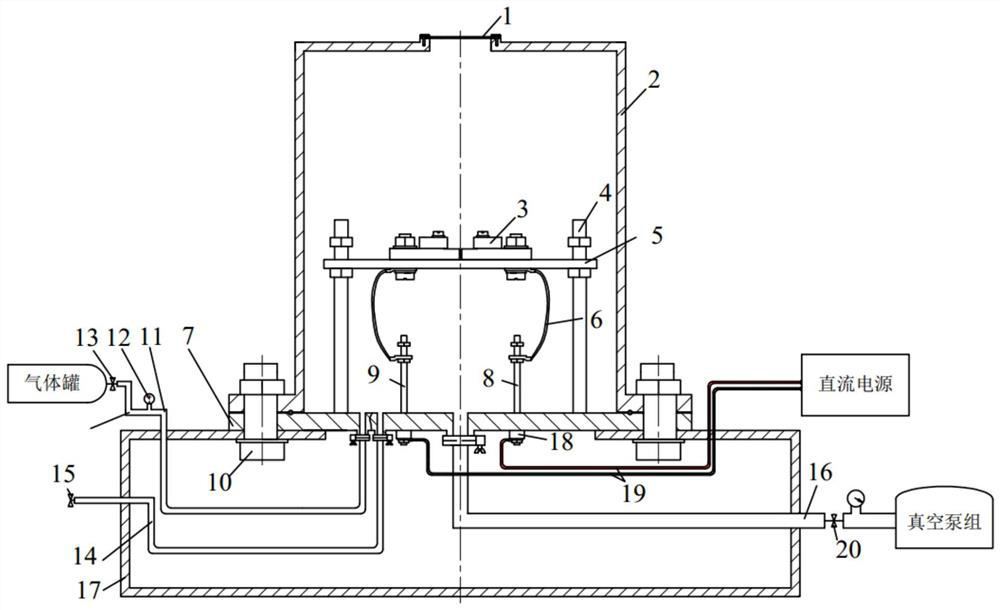

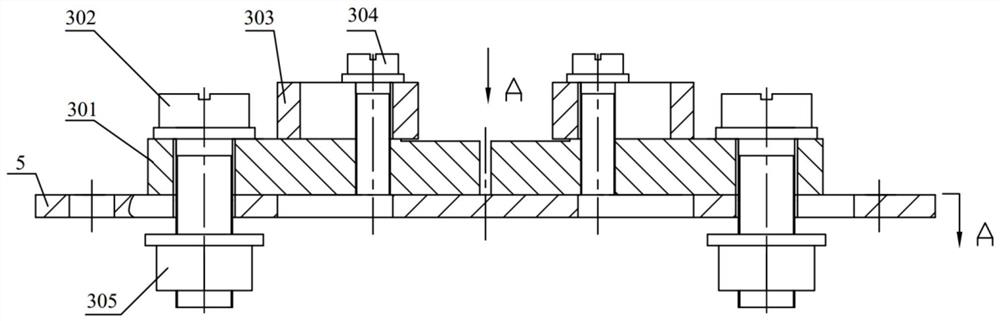

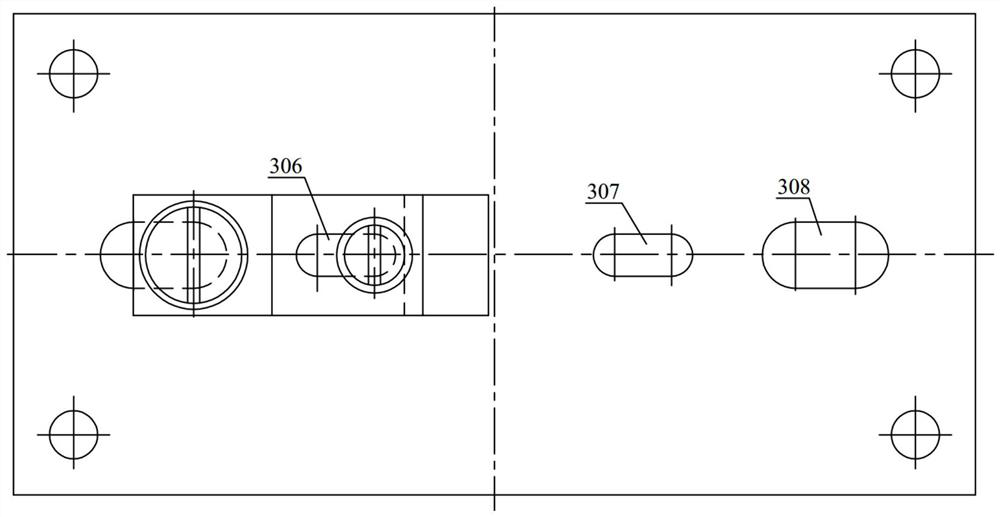

[0032] Such as figure 1 It is a two-dimensional schematic diagram of the current heating rapid annealing furnace of the present invention, including an observation window 1, a protective cover 2, a heating fixture 3, a support column 4, a support plate 5, a connecting wire 6, a vacuum-sealed electrode flange 7, a heating electrode positive electrode 8, Heating electrode negative pole 9, bolt 10, air intake pipe 11, flow meter 12, air intake valve 13, air release pipe 14, air release valve 15, air outlet pipe 16, base 17, insulating ceramics 18, DC power cord 19, air outlet valve 20.

[0033] The vacuum cavity is connected by the protective cover 2 and the vacuum-sealed electrode flange 7 through the CF flange, which can reach a high vacuum level. Further, the upper side of the protective cover 2 is provided with an observation window ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com