Recombinant bacteria for producing gamma-aminobutyric acid by glycerin and construction method of recombinant bacteria

A technology of aminobutyric acid and its construction method, which is applied in the fields of synthetic biology and metabolic engineering, can solve problems such as low yield and inability to meet actual production needs, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

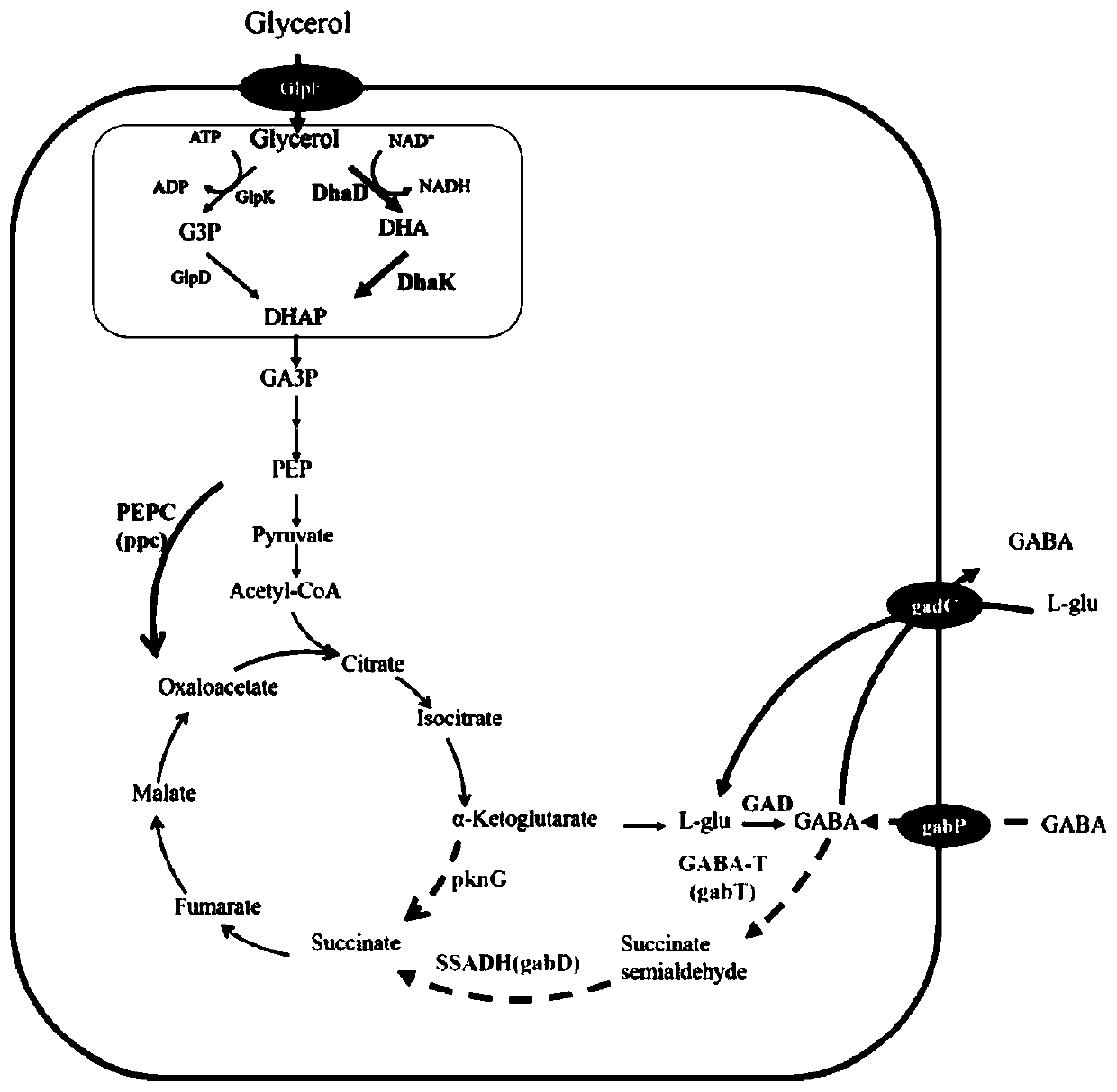

[0023] Embodiment 1 improves the strain construction of the Corynebacterium glutamicum of glycerol utilization efficiency

[0024] (1) Design RBS random mutation primers for the three genes glpF, dhaD, and dhaK in the glycerol utilization pathway and the pEC-XK99E plasmid. The primer sequences used are:

[0025] glpF-F: 5'-caccaggtctcacacaaaaggannnnnnnnnatgagtcaaacatcaaccttgaaag-3'

[0026] glpF-R: 5'-caccaggtctcagactgcttacagcgaagctttttgttctg-3'

[0027] dhaD-F: 5'-caccaggtct caagtcaaaggannnnnnnnnatgctaaaagttatcaatctccagc-3'

[0028] dhaD-R: 5'-caccaggtctcacctgggttaacgcgccagccactgctgtc-3'

[0029] dhaK-F: 5'-caccaggtctcacaggaaaggannnnnnnnnatgtctcaattcttttttaaccaacg-3'

[0030] dhaK-R: 5'-caccaggtctcacgttacccttagcccagctcactctccgccag-3'

[0031] pEC-XK99E-F: 5'-caccaggtctcaaacgggcggagagtgagctgggc-3'

[0032] pEC-XK99E-R: 5'-caccaggtctcatgtgaaattgttatccgctcacaattcc-3'

[0033] The pEC-XK99E-glpFDK plasmid was used as a template, and the above primers were used for PCR ampl...

Embodiment 2

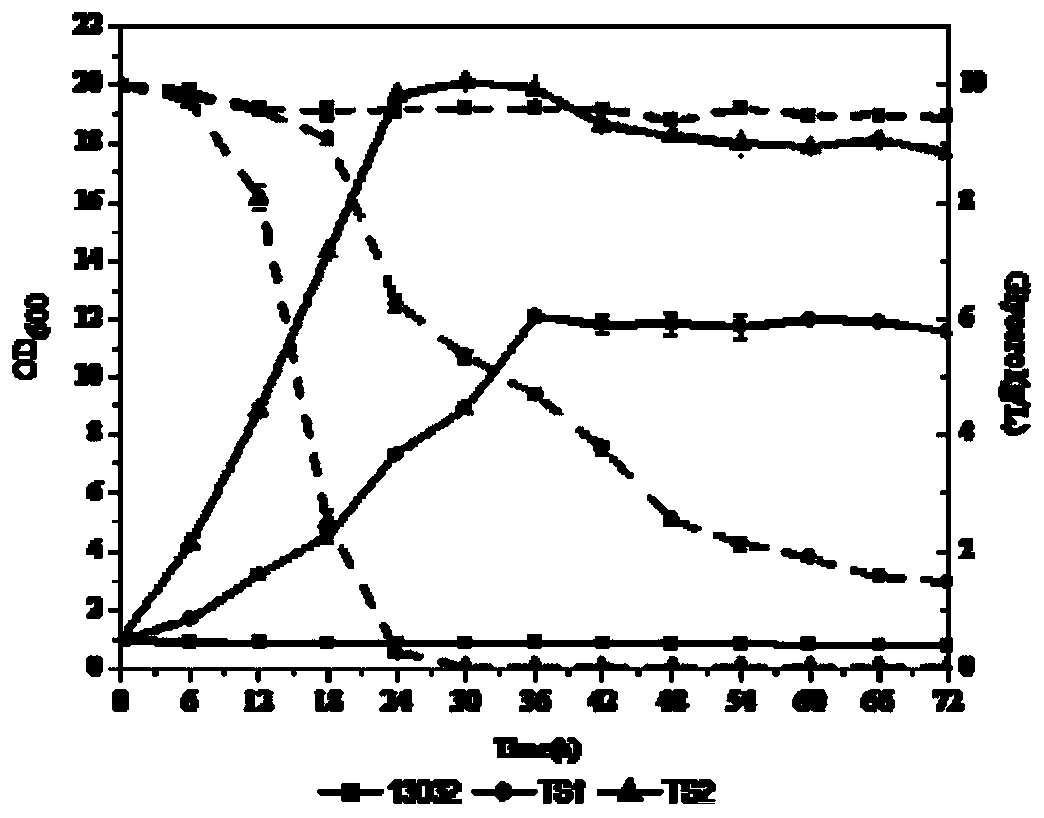

[0037] Example 2 Construction of different RBS intensities overexpressing Bacillus megaterium glutamic acid decarboxylase gene gad strain

[0038] (1) First extract the pET21b-Bmgad plasmid from the DH5α / pET21b-Bmgad strain, extract the pXMJ19 plasmid from the DH5α / pXMJ19 strain, and then use the primer pairs gad-F / gad-R and pXMJ19-F / pXMJ19-R to amplify The gad gene fragment and the pXMJ19 vector fragment were obtained by using Golden Gate assembly technology to obtain the plasmid pXMJ19-gad. The gad-H gene fragment was amplified with primers gad-H-F / RBS-gad-R, and the gad-L gene fragment was amplified with primers gad-L-F / RBS-gad-R. Use the GoldenGate assembly technology to connect the above fragments to the vector pXMJ19 to obtain plasmids pXMJ19-gad and pXMJ19-gad H , pXMJ19-gad L . The primer sequences used are:

[0039] gad-F: 5'-gaaggagatatacatatgccacagtggcacccacaccgcg-3'

[0040] gad-R: 5'-gcctttttgcgtttctacaaactcttttgtttatttttc-3'

[0041] pXMJ19-F: 5'-gtttctacaa...

Embodiment 3

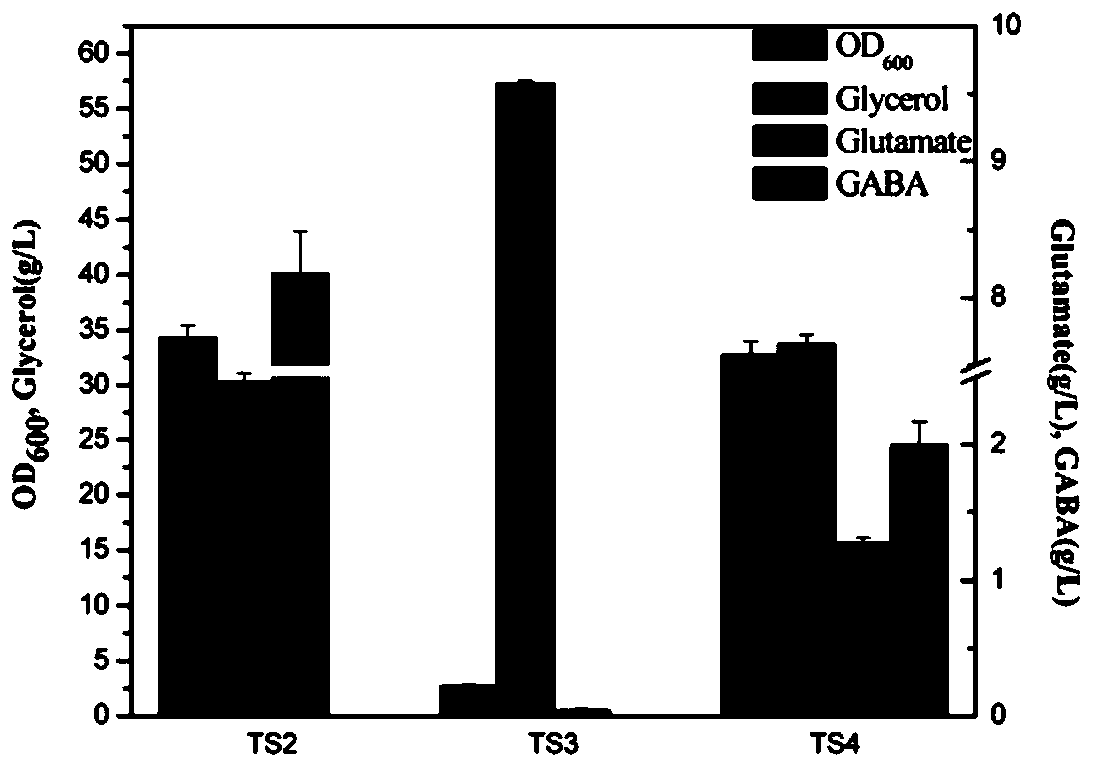

[0048] Example 3 Construction of Corynebacterium glutamicum serine / threonine-protein kinase gene pknG deletion strain

[0049] (1) Using the genome of C. glutamicum ATCC 13032 as a template, the pknG-up fragment and pknG- dn fragment. The upper homology arm and the lower homology arm are connected by fusion PCR technology. The fused fragment was treated with HindIII and XbaI enzymes, and connected to the temperature-sensitive knockout vector pCRD206 to obtain the knockout plasmid pCRD206-pknG. The primer sequences used are:

[0050] pknG-up-F: 5'-agtgaagcttattttcggtgaccccaataagg-3'

[0051] pknG-up-R: 5'-caaatagccccaagtcaaaacagcgttttctgtcccttcttcctc-3'

[0052] pknG-dn-F: 5'-ctgttttgacttggggctatttg-3'

[0053] pknG-dn-R: 5'-tctgtctagagaaaatgcccagtttgtccgt-3'

[0054] (3) pknG gene knockout step: the plasmid pCRD206-pknG was electrotransformed into C. glutamicum ATCC 13032 competent cells. Pick the transformant and put it into a test tube of 3mL resistant LBHIS liquid me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com