A graphene-coated metal nanowire network and preparation method thereof

A technology coated with metal nanowires and graphene, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as poor stability, lower transmittance or electrical conductivity, and achieve improved The effect of stability, easy control, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

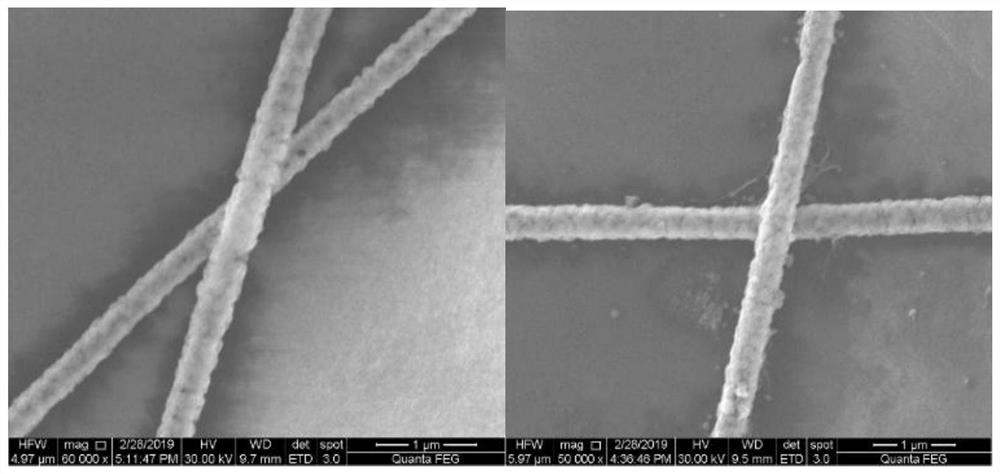

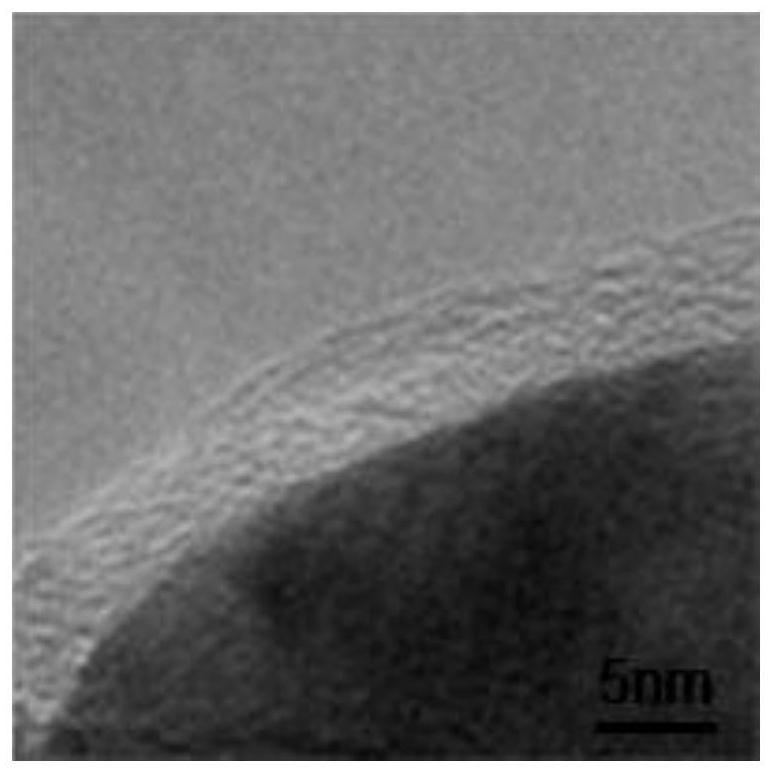

[0051] Embodiment 1, the preparation of the silver nanowire grid coated with graphene

[0052] First, preparation of silver nanowire network by solution method: electrospinning and preparation of silver seed layer: first, preparation of electrospinning precursor solution. 8% PVB and 5% SnCl 2 Dissolve in n-butanol, place on a magnetic stirrer, keep the rotation speed at 600 rpm, and stir for 4 hours. Then, PVB / SnCl was spun out using electrospinning equipment 2 For nanofibers, the collection device is a glass slide. The conditions of electrospinning were as follows: the applied voltage was +8 kV, the distance between the nozzle and the collector was 20 cm, and the flow rate of the precursor solution was 0.6 mL / h.

[0053] Electroless deposition of silver: The process of electroless deposition is realized by silver mirror reaction. The sample that has grown the silver seed layer is vertically immersed in a uniformly stirred 5g / L glucose solution, and the glucose solution is...

Embodiment 2

[0060] Embodiment 2, the preparation of the silver nanowire grid coated with zinc oxide

[0061] First, a silver nanowire network was prepared in the same manner as in Example 1.

[0062] Then, zinc nitrate aqueous solution (concentration: 0.1M / L) was used as the electrolyte, heated in a water bath at 70°C, the prepared silver nanowire network was used as the cathode, and the zinc sheet was used as the anode, the applied current was 15mA, and the reaction time was 10s. Zinc-coated silver nanowire network.

[0063] The scanning electron micrograph of the silver nanowire coated with zinc oxide prepared in this embodiment is as follows Figure 5 As shown, it can be seen that zinc oxide exists on the surface of the silver nanowires by comparing the silver nanowires alone.

[0064] The silver nanowire network prepared in this example and the zinc oxide-coated silver nanowire network are kept at a relative humidity of 85% and a temperature of 85°C for 110 hours. Figure 6 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com