Amorphous nanocrystalline soft magnetic material and preparation method and application thereof, amorphous strip, amorphous nanocrystalline strip and amorphous nanocrystalline magnetic sheet

An amorphous nanocrystalline, soft magnetic material technology, applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of saturation magnetic induction intensity and coercive force can not be balanced, to improve the ability to form amorphous , Balance saturation magnetic induction and coercivity, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0079] 1. Ingredients: raw materials with a purity greater than 99% 80 Si 4 B 9 Cu 1 P 5.8 (NbC) 0.2 The alloy components are mixed, in which B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, Nb in the form of niobium-iron alloy, C in the form of iron-carbon alloy, and other elements are added in the form of simple substances.

[0080] 2. Melting: Put the raw materials with a good ratio into the crucible of the melting furnace, and use electric arc melting at 1400°C to obtain an alloy ingot with uniform composition under the vacuum state.

[0081] 3. Manufacturing of amorphous alloy: after remelting the alloy ingot described in step 2, quenching is carried out by a single-roller quenching method, and the cooling rate of quenching is 10 6 °C / s or more, a strip-shaped amorphous alloy is obtained.

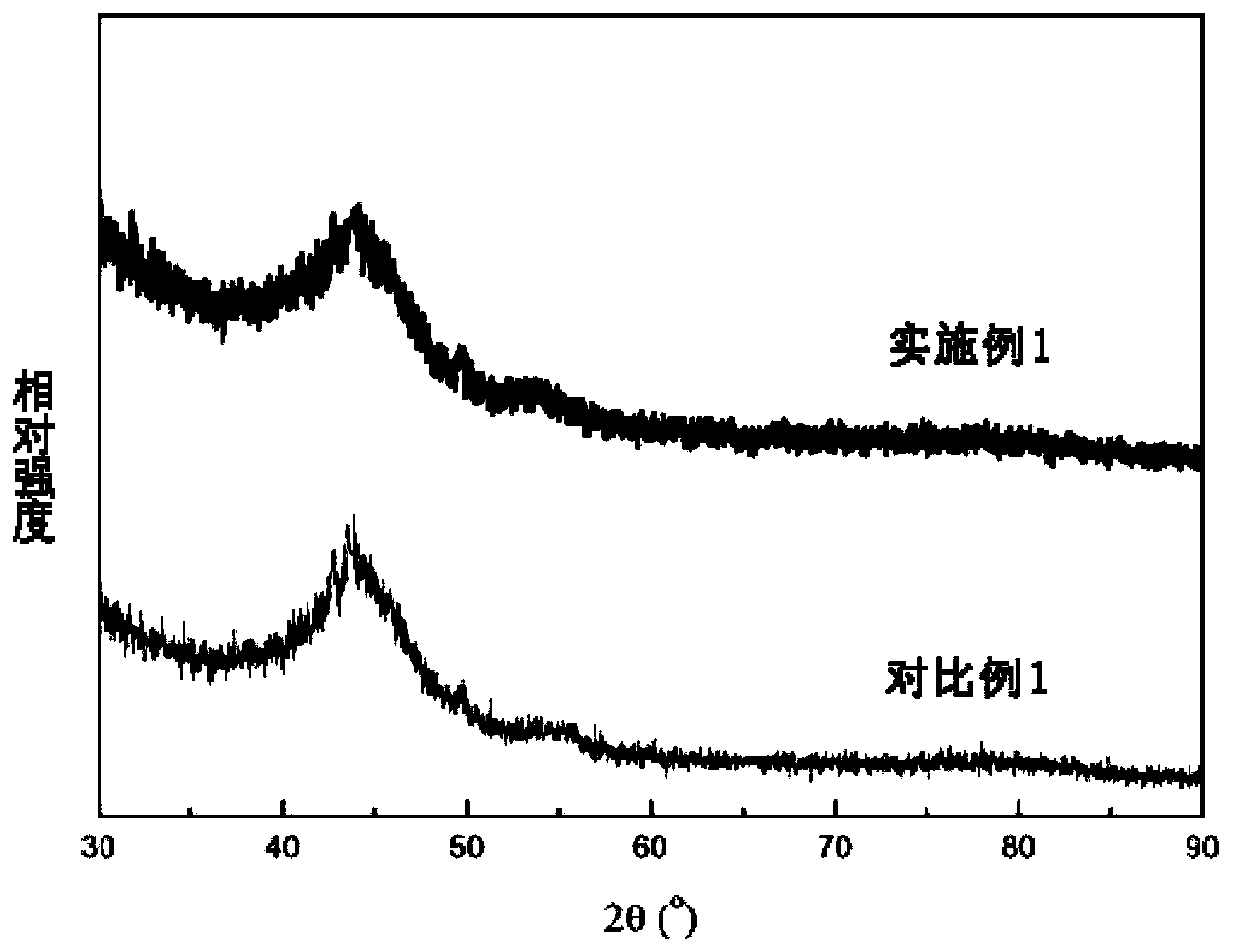

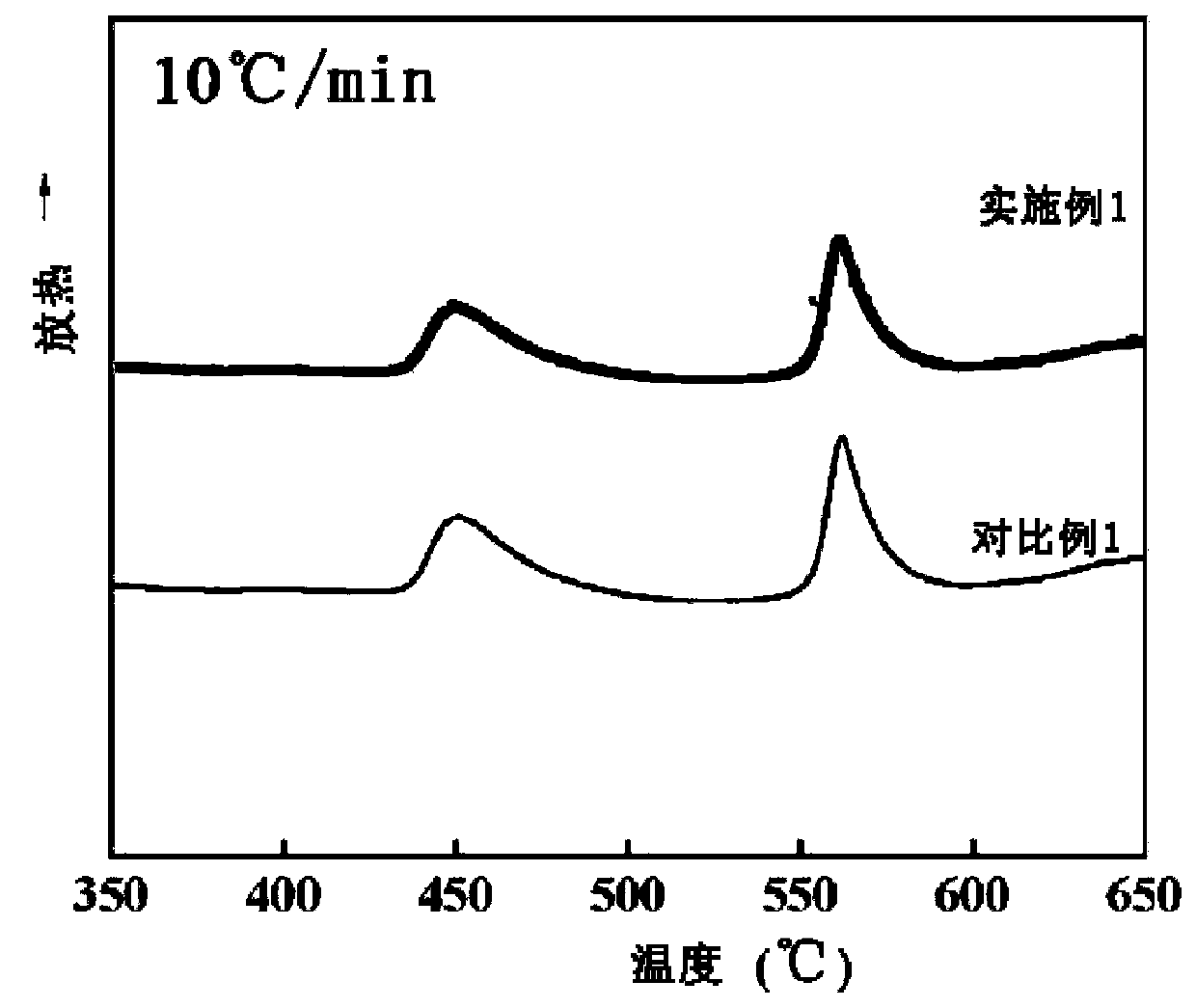

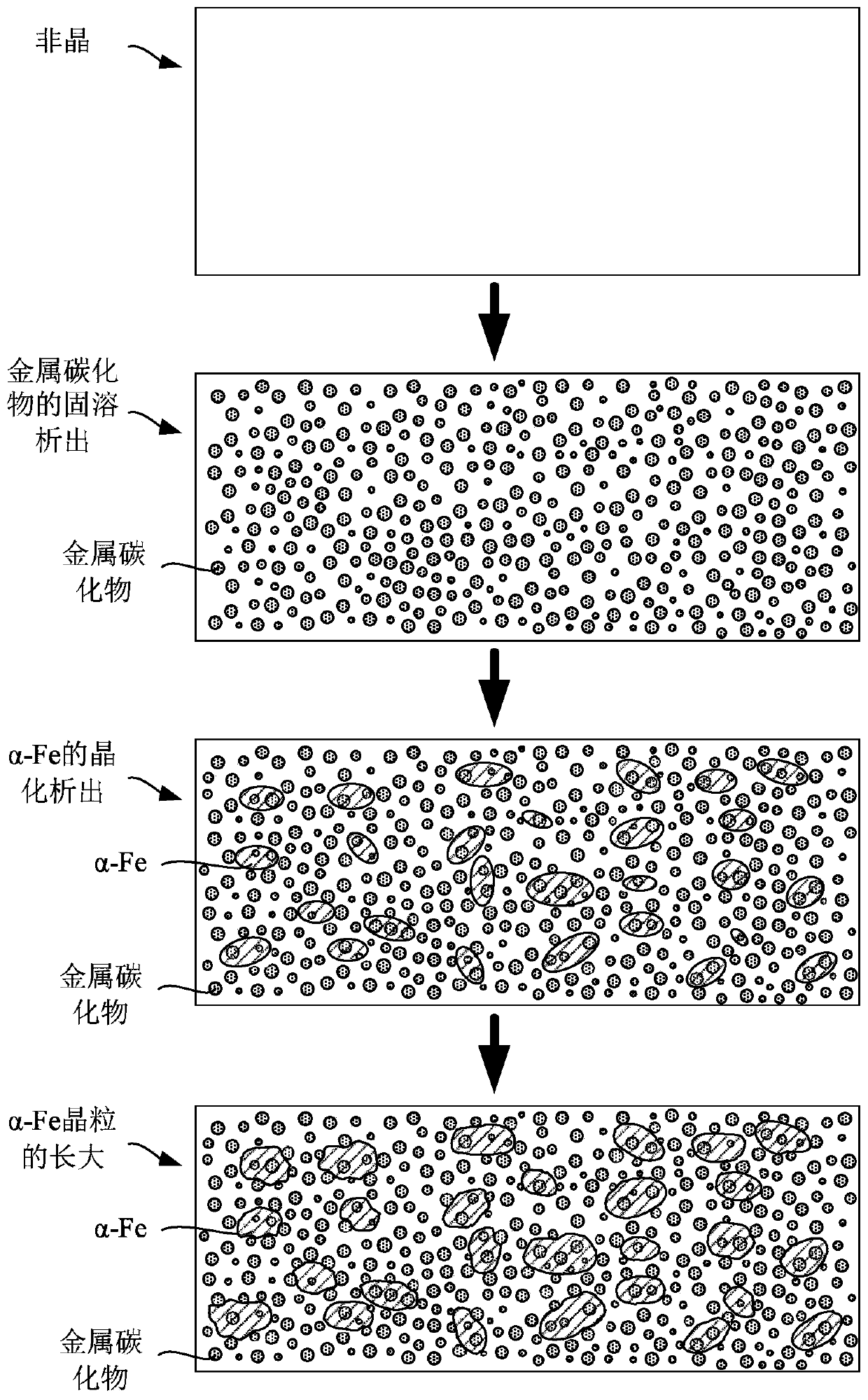

[0082] Carry out XRD (X-...

Embodiment 2

[0099]This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0100] 1. Ingredients: raw materials with a purity greater than 99% 78 Si 4 B 9 Cu 1 P 7.8 (NbC) 0.2 The alloy components are mixed, in which B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, Nb in the form of niobium-iron alloy, C in the form of iron-carbon alloy, and other elements are added in the form of simple substances.

[0101] 2. Melting: put the well-proportioned raw materials into the crucible of the melting furnace, and use electric arc melting at 1300°C in a nitrogen atmosphere to obtain an alloy ingot with a uniform composition.

[0102] 3. Manufacturing of amorphous alloy: after remelting the alloy ingot described in step 2, quenching is carried out by a single-roller quenching method, and the cooling rate of quenching is 10 6 °C / s or more, a strip-shaped amorphous alloy is obtained.

[0103] 4. Crystalliza...

Embodiment 3

[0113] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0114] 1. Ingredients: raw materials with a purity greater than 99% 83 Si 2 B 9 Cu 1 P 4.8 (NbC) 0.2 The alloy components are mixed, in which B is added in the form of boron-iron alloy, P in the form of phosphorus-iron alloy, Nb in the form of niobium-iron alloy, C in the form of iron-carbon alloy, and other elements are added in the form of simple substances.

[0115] 2. Melting: Put the well-proportioned raw materials into the crucible of the smelting furnace, and use arc melting at 1500°C in an argon atmosphere to obtain an alloy ingot with a uniform composition.

[0116] 3. Manufacturing of amorphous alloy: after remelting the alloy ingot described in step 2, quenching is carried out by a single-roller quenching method, and the cooling rate of quenching is 10 6 °C / s or more, a strip-shaped amorphous alloy is obtained.

[0117] 4. Crystallization: Cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com