Method for preparing palm oil with low content of glycidyl ester and 3-MCPD ester

A glycidyl ester and palm oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of high glycidyl ester, palm oil human health hazards, high 3-MCPD ester content level, etc., to reduce pollution, The effect of reducing the difficulty of refining and reducing the cost of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

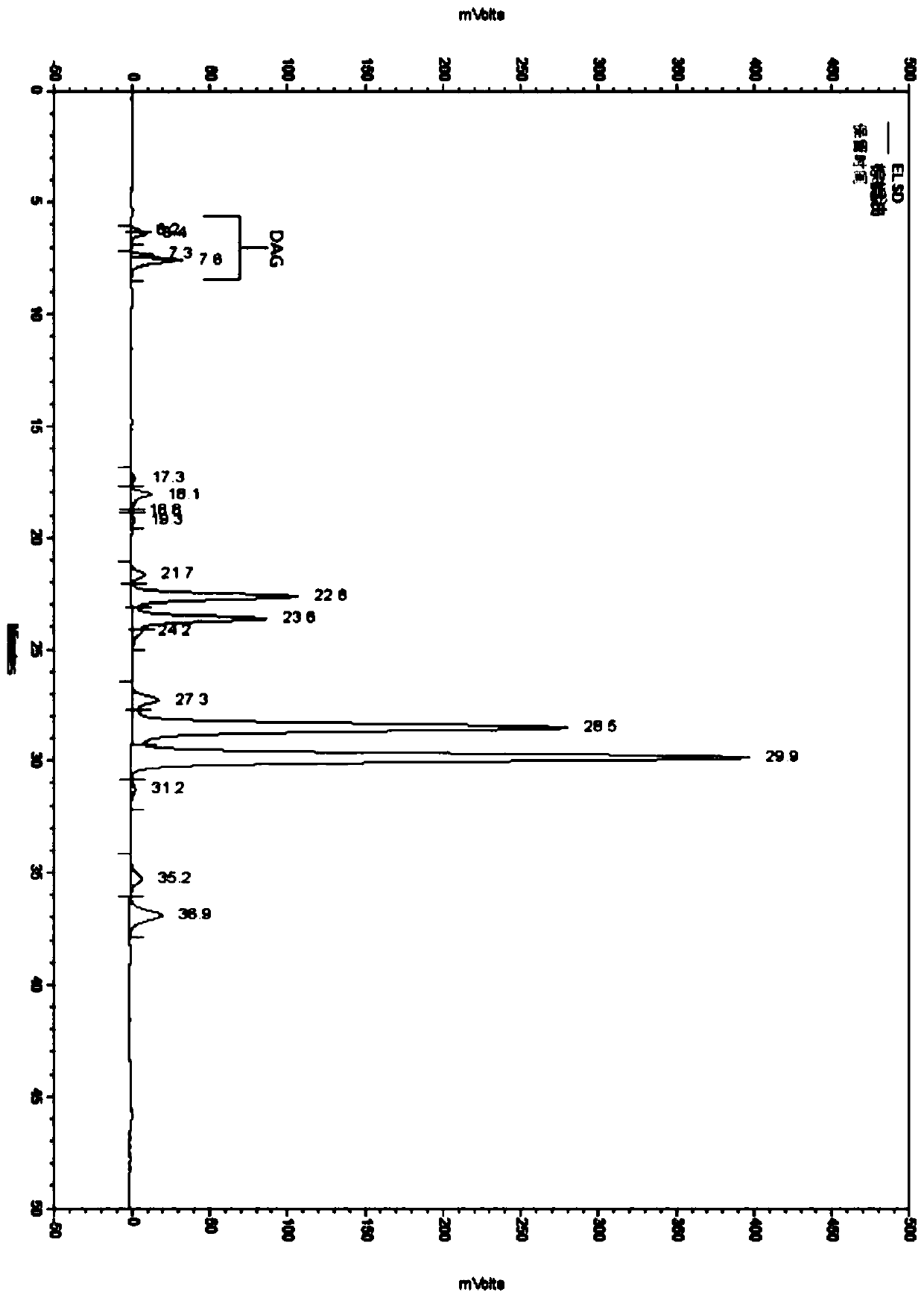

Embodiment 1

[0033] A method for preparing palm oil with low glycidyl ester and low 3-MCPD ester content, comprising the following preparation steps:

[0034] A, carry out degumming process to palm oil;

[0035] B, carry out solvent fractionation to the palm oil after described step A degumming treatment, then carry out deodorization treatment, obtain the grease of low diglyceride content;

[0036] C. Carry out refining treatment to the oil with low diglyceride content in the step B to obtain palm oil with low glycidyl ester and low 3-MCPD ester content.

[0037] Wherein, the degumming treatment and deodorization treatment are existing conventional processes, and the specific steps thereof will not be repeated here. The refining treatment in the step C adopts conventional process conditions for refining, and the specific steps are not repeated here.

[0038] Wherein, the solvent fractionation in the step B comprises the following steps:

[0039] (1) In a temperature-controlled stirring ...

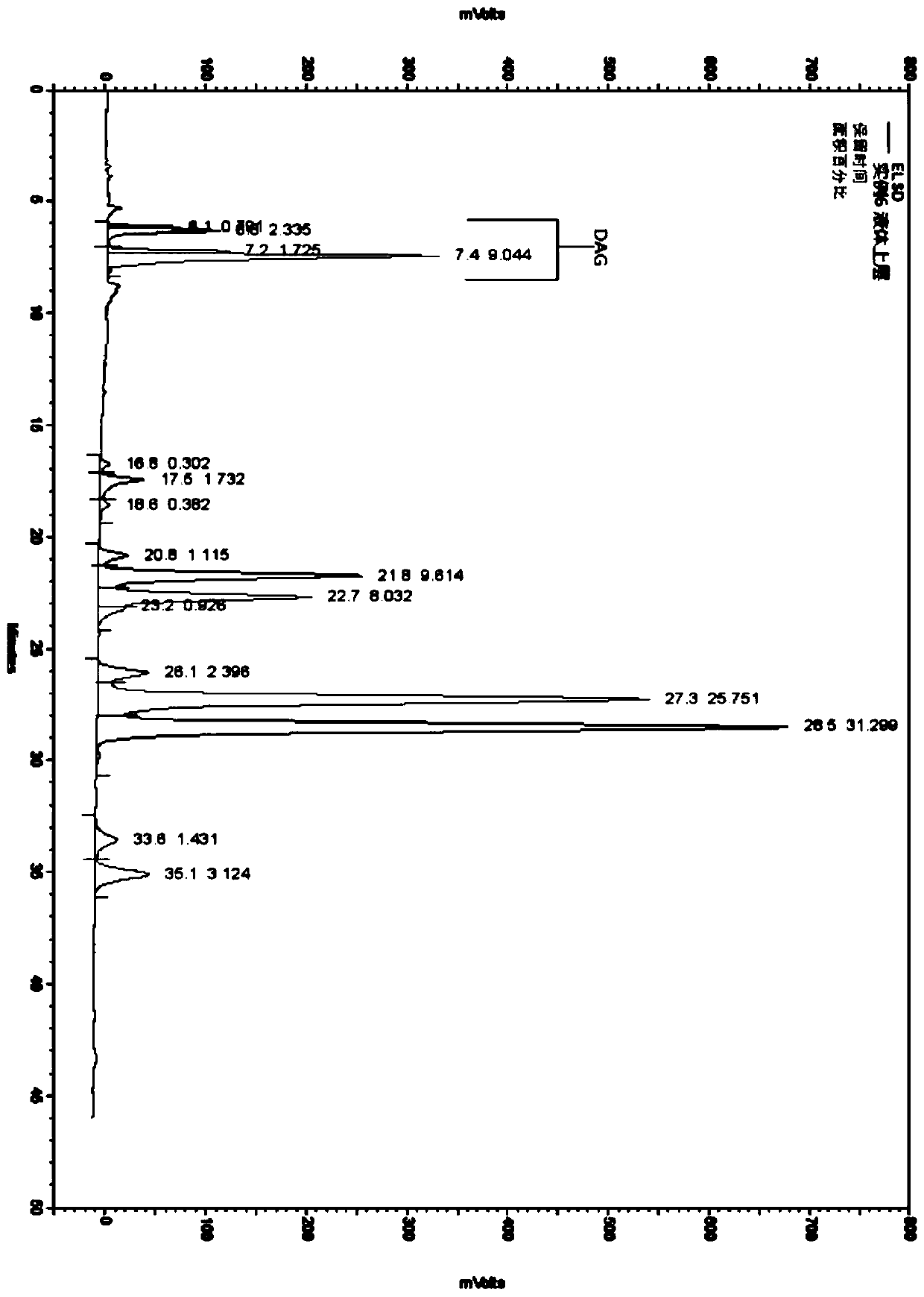

Embodiment 2

[0043] A method for preparing palm oil with low glycidyl ester and low 3-MCPD ester content, comprising the following preparation steps:

[0044] A, carry out degumming process to palm oil;

[0045] B, carry out solvent fractionation to the palm oil after described step A degumming treatment, then carry out deodorization treatment, obtain the grease of low diglyceride content;

[0046] C. Carry out refining treatment to the oil with low diglyceride content in the step B to obtain palm oil with low glycidyl ester and low 3-MCPD ester content.

[0047] Wherein, the degumming treatment and deodorization treatment are existing conventional processes, and the specific steps thereof will not be repeated here. The refining treatment in the step C adopts conventional process conditions for refining, and the specific steps are not repeated here.

[0048] Wherein, the solvent fractionation in the step B comprises the following steps:

[0049](1) In a temperature-controlled stirring s...

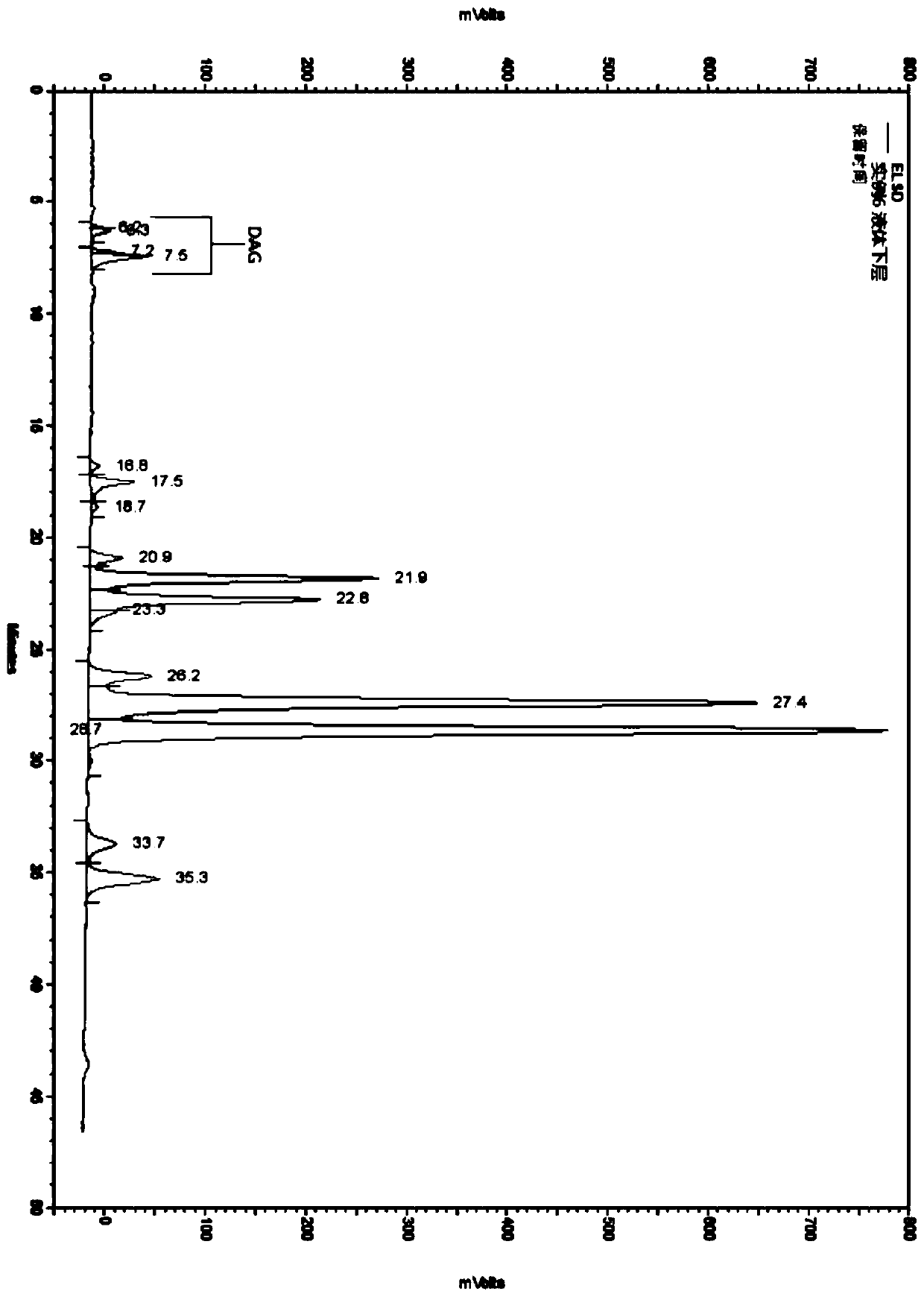

Embodiment 3

[0053] A kind of method for preparing the palm oil of low glycidyl ester and low 3-MCPD ester content, the difference of embodiment 3 and embodiment 2 is, adopt 150mL after described step A degumming process when carrying out solvent fractionation in step B The palm oil mixed with the mixed solvent that is made up of 125mL normal hexane and 75mL dehydrated alcohol, other operating steps and operating conditions of embodiment 3 are identical with embodiment 2, do not repeat them here.

[0054] The content of diglyceride in the oil with low diglyceride content is 1.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com