A kind of environment-friendly strong water-resistant wood paint and preparation method thereof

A kind of wood lacquer and environmental protection technology, applied in the field of wood lacquer, can solve the problems of reduced protection effect, water resistance, surface unevenness, etc., and achieve the effect of improving protection effect, improving water resistance, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

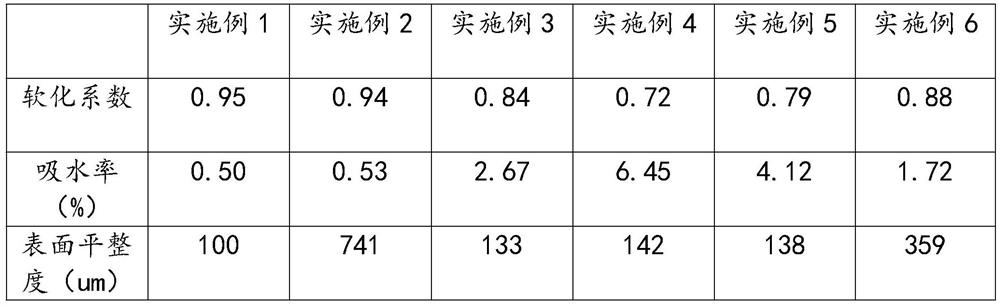

Examples

Embodiment 1

[0032] An environment-friendly strong water-resistant wood paint, which is composed of a primer paint and a coating paint, and the raw materials in the primer paint are respectively 55% water-based acrylic resin, 30% filler, and 10% lauryl Sodium sulfate and 5% methyl silicone oil; the filler is mixed with wood powder, mica powder, micro wax powder and calcium silicate powder in a weight percentage of 1:1:1:1;

[0033] The primer paint is prepared by the following method: firstly introduce the water-based acrylic resin and methyl silicone oil into the mixing tank, blend at 300 rpm and 90 degrees for 30 minutes, and then add the filler and sodium lauryl sulfate together Introduce it, and blend at 210 rpm, pressurized at 2.5MPa and 60 degrees for 90 minutes, reduce the temperature under reduced pressure, filter to remove impurities and concentrate to 2 / 5 to obtain the primer;

[0034] The raw materials in the coating paint are respectively 50% deionized water, 20% modified base ...

Embodiment 2

[0045] A kind of environment-friendly strong water-resistant wooden ware paint, differs from embodiment 1 in that it is only made up of coating paint material, without primer paint material and related content thereof;

[0046] And the application method of the environmental-friendly strong water-resistant wood lacquer is as follows: first, the coating paint is heated to 75 degrees, and then it is evenly coated on the surface of the wooden product, and after being dried by hot air, the coating paint surface is obtained.

[0047] A kind of preparation method of environment-friendly strong water-resistant wood lacquer, differs from the embodiment 1 in that it only consists of the preparation of coating paint, without 1) the preparation of bottom paint.

Embodiment 3

[0049] An environment-friendly strong water-resistant wood varnish, the difference from Example 1 is that the modified base material is completely replaced with acrylic resin, and the relevant content on the preparation of the original modified base material is deleted.

[0050] A preparation method of an environment-friendly strong water-resistant wood lacquer, the difference from Example 1 is that 2) the modified base material is all replaced by acrylic resin in the preparation of the coating paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com