Preparation method of lithium titanate negative pole piece, lithium titanate negative pole piece and lithium ion battery containing negative pole piece

A technology of negative pole piece, lithium titanate, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of restricting the application and development of lithium ion batteries, large internal resistance of batteries, and high internal energy consumption, etc., to improve discharge capacity. As well as cycle stability, improve electrical conductivity, and avoid the effects of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

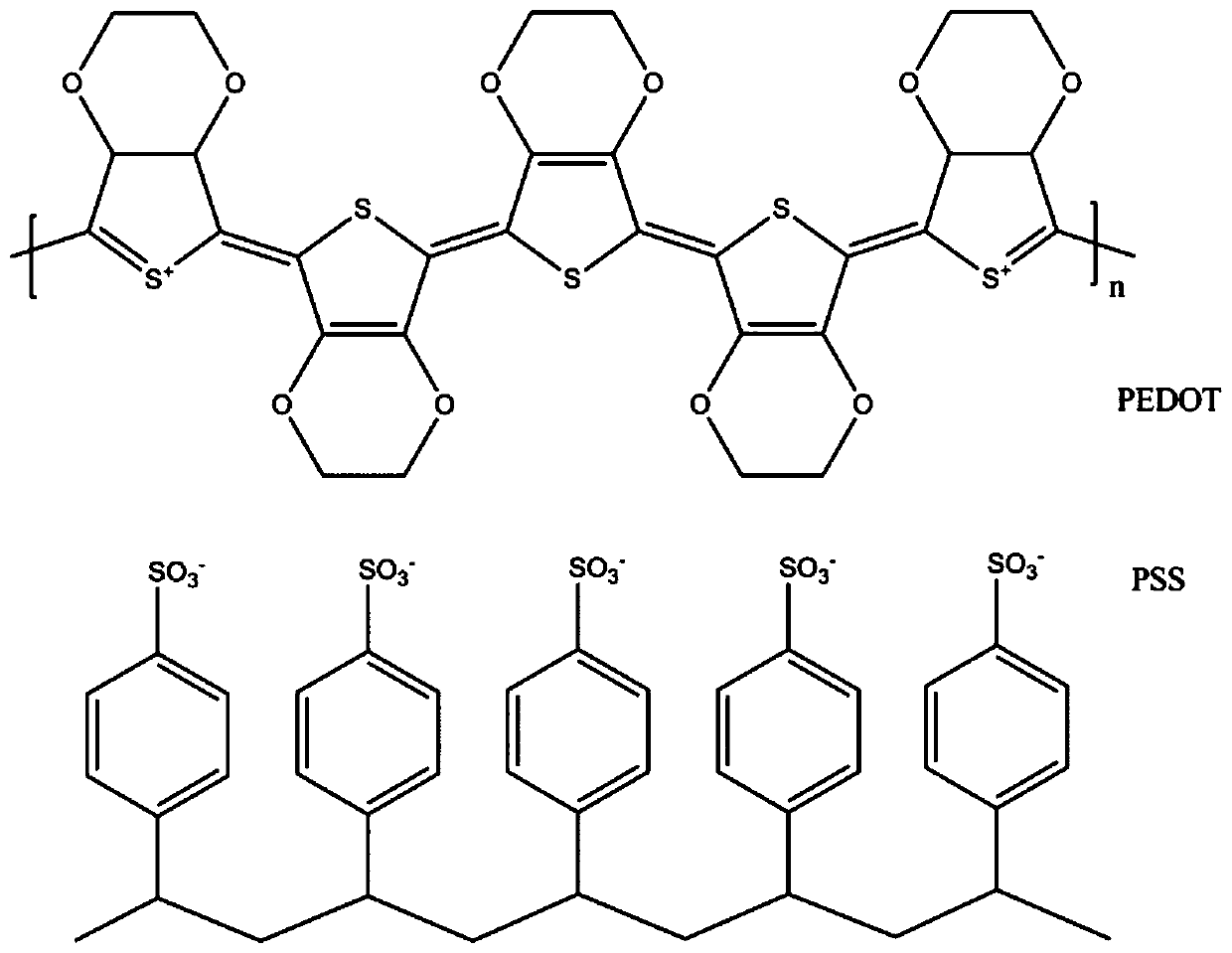

[0045] 1. Add EDOT to the PSS solution at a molar ratio of 1:2, ultrasonically mix at room temperature for 60 minutes, and add a stirring magnet to keep stirring during the subsequent reaction process, with a rotation speed of 1000 rpm;

[0046] 2. Configure dilute hydrochloric acid with a fixed concentration (1M), and then slowly adjust the pH value of the solution in step 1 to 3 with dilute hydrochloric acid;

[0047] 3. Put the reaction container in an ice-water bath and keep it warm for 6 hours, then prepare the ammonium persulfate solution according to the molar ratio of the initiator ammonium persulfate to the monomer EDOT of 1:20, and slowly add it dropwise to step (2) In the solution, after the dropwise addition, continue to react for 24 hours under the conditions of ice-water bath and magnetic stirring at a constant speed, and finally a dark green solution A can be obtained;

[0048] 4. Select an ion-exchange column based on silanized silica gel, first activate the st...

Embodiment 2

[0052] Embodiment 2: The molar ratio of polymer monomer and PSS is changed to 1:4

[0053] Effects after substitution: The increase or decrease of PSS content will affect the conductivity of the polymer solution, thereby affecting the conductivity of the battery pole piece

Embodiment 3

[0054] Embodiment 3: Stirring speed is changed to 200 rev / mins during reaction

[0055] Effects after substitution: The stirring rate can affect the length of the molecular chain, thereby affecting the conductivity and cycle performance of the conductive battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com