Preparation method of patterned AgNWs/PEDOT:PSS composite conductive lattice thin film

A composite conductive and patterning technology, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve electrode performance degradation, film uniformity limitations, difficulties, etc. problem, to achieve the effect of improving conductivity and adhesion, good conductive uniformity, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

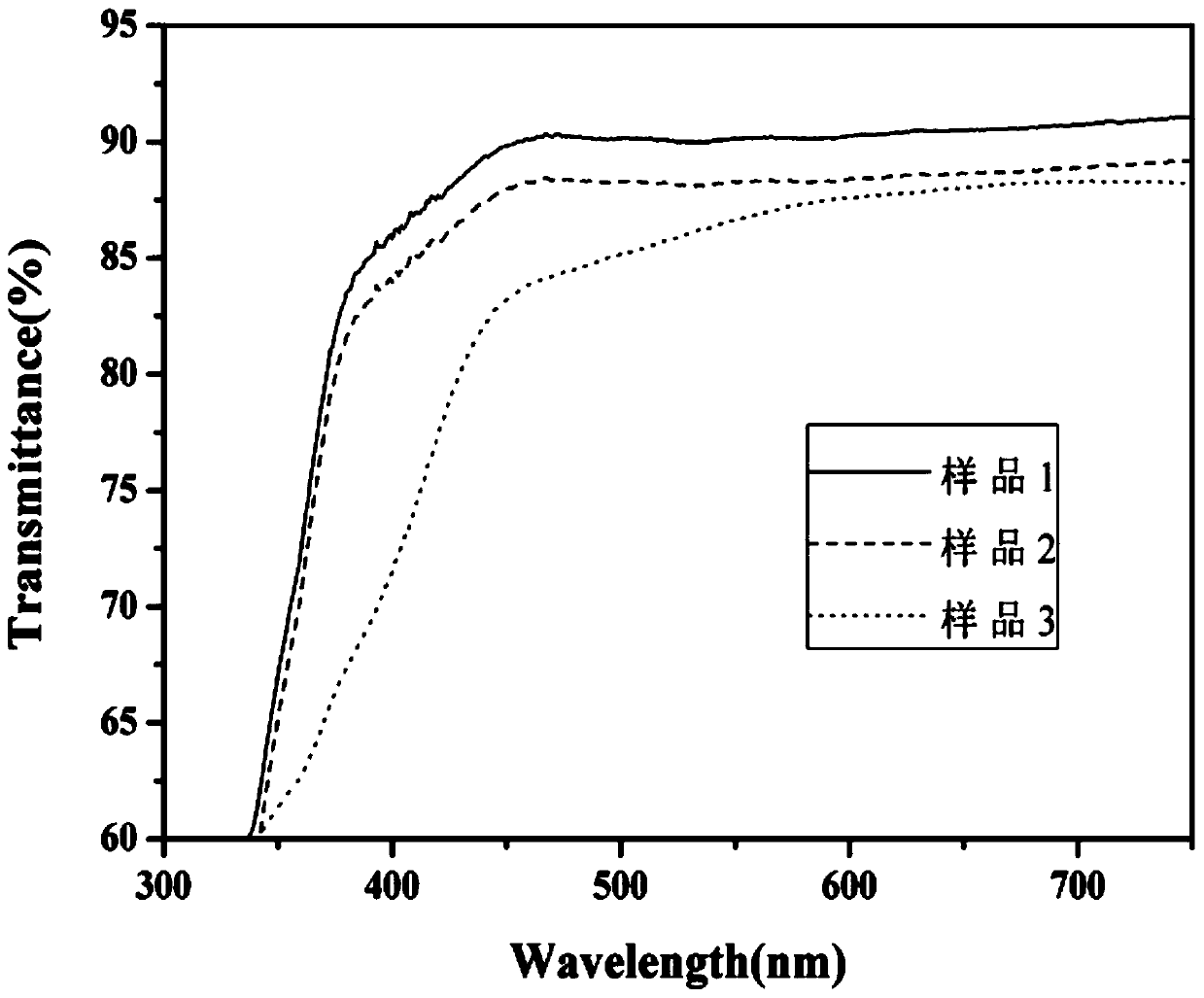

Embodiment 1

[0033] A method for preparing a patterned AgNWs / PEDOT:PSS composite conductive grid film, specifically comprising the following steps:

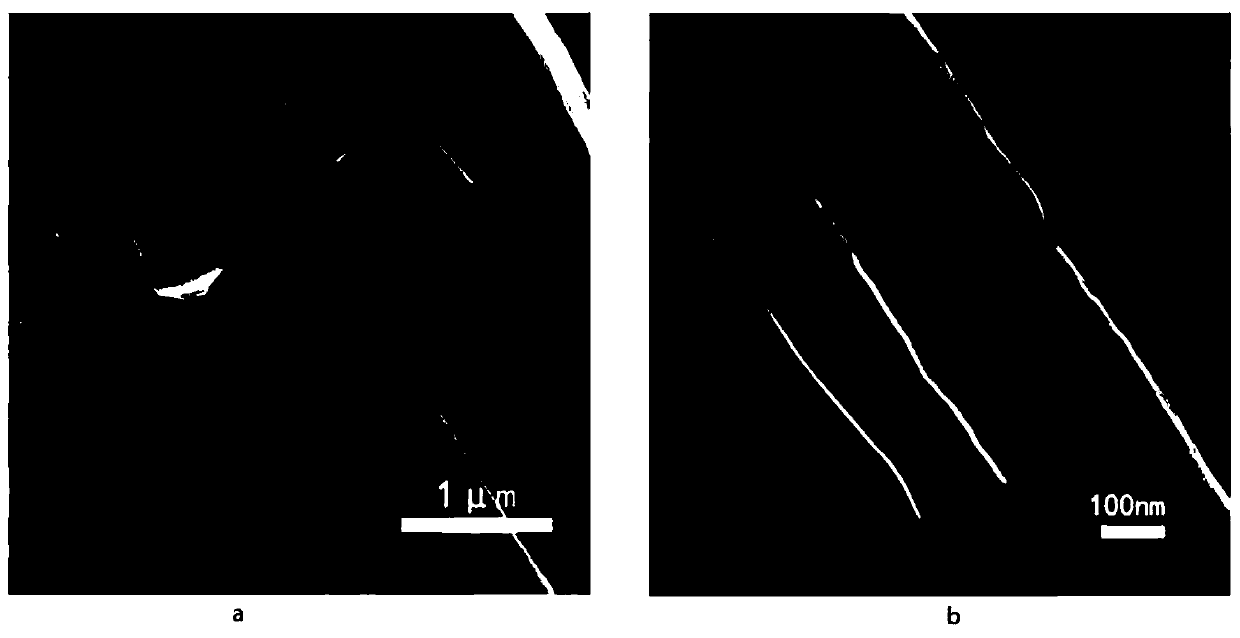

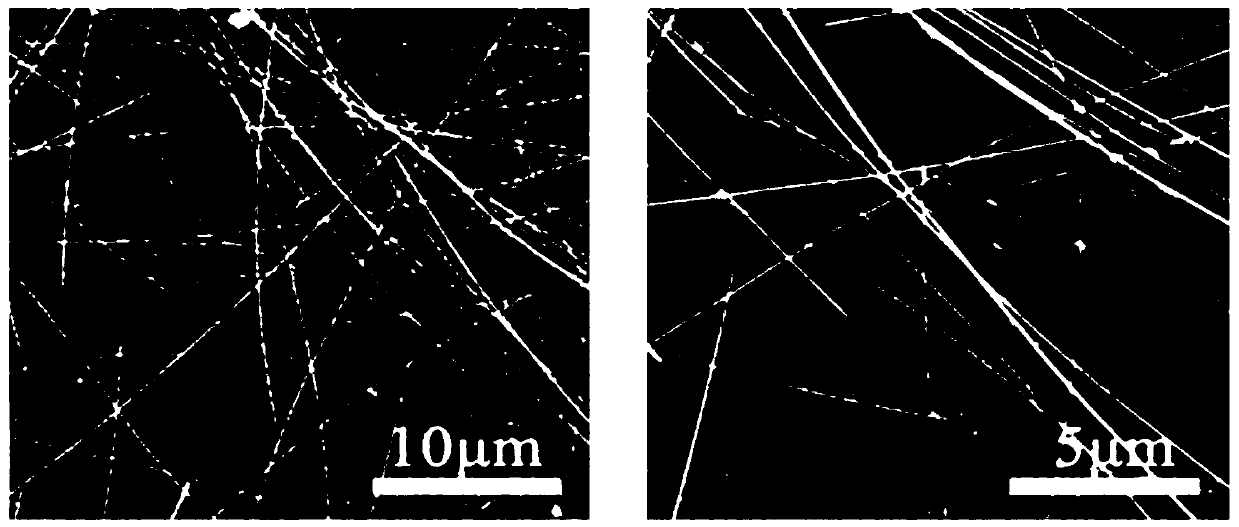

[0034] S1), preparation of silver nanowires with higher aspect ratio

[0035] S101), at room temperature, 0.7536g of glucose, 0.1559g of silver nitrate and 0.1920g of ferric sulfate were added to deionized water (DI) to dissolve, and mixed and stirred for 30min until a bright yellow solution was produced;

[0036] S102), adding 1 g of polyvinylpyrrolidone (PVP, K30) to the above mixed solution, and continuously stirring and mixing until the polyvinylpyrrolidone (PVP, K30) is completely dissolved;

[0037] S103), then transfer the mixed solution in step S102) to a 100mL reaction kettle, then seal it and put it in an oven, heat it at 160°C for 6h, and after cooling to room temperature, take out the reaction kettle and remove the upper layer Black waste liquid, a gray precipitate was obtained;

[0038] S104), add ethanol to the above gray prec...

Embodiment 2

[0049] A method for preparing a patterned AgNWs / PEDOT:PSS composite conductive grid film, specifically comprising the following steps:

[0050] S1), preparation of silver nanowires with higher aspect ratio

[0051] S101), at room temperature, 0.7536g of glucose, 0.2539g of silver nitrate and 0.2053g of ferric sulfate were added into deionized water (DI) to dissolve, and mixed and stirred for 60min until a bright yellow solution was produced;

[0052] S102), adding 3 g of polyvinylpyrrolidone (PVP, K30) to the above mixed solution, and continuously stirring and mixing until the polyvinylpyrrolidone (PVP, K30) is completely dissolved;

[0053] S103), then transfer the mixed solution in step S102) to a 100mL reaction kettle, then seal it and put it in an oven, heat it at 180°C for 7h, and after cooling to room temperature, take out the reaction kettle and remove the upper layer Black waste liquid, a gray precipitate was obtained;

[0054] S104), add ethanol to the above gray pr...

Embodiment 3

[0064] A method for preparing a patterned AgNWs / PEDOT:PSS composite conductive grid film, specifically comprising the following steps:

[0065] S1), preparation of silver nanowires with higher aspect ratio

[0066] S101), at room temperature, 0.7536g of glucose, 0.2569g of silver nitrate and 0.2450g of ferric sulfate were respectively added to deionized water (DI) to dissolve, and mixed and stirred for 90min until a bright yellow solution was produced;

[0067] S102), adding 4.5 g of polyvinylpyrrolidone (PVP, K30) to the above mixed solution, and continuously stirring and mixing until the polyvinylpyrrolidone (PVP, K30) is completely dissolved;

[0068] S103), then transfer the mixed solution in step S102) to a 100mL reaction kettle, then seal it and put it in an oven, heat it at 190°C for 8h, and after cooling to room temperature, take out the reaction kettle and remove the upper layer Black waste liquid, a gray precipitate was obtained;

[0069] S104), add ethanol to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com