Special Zygosaccharomyces rouxii for fermented sauce with fragrance increasing and color reducing functions and application thereof

A technology of fermented sauce and yeast, which is applied in the direction of yeast-containing food ingredients, food ingredients as color, and methods based on microorganisms, etc., which can solve the problem of difficulty in ensuring stable output of high-quality fermented sauce, insufficient aroma of fermented sauce products, and batch differences Larger problems, to achieve the effect of strong adaptability, soft and bright color, strong salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Application of Zygosaccharomyces rouxii Piniang J028 in Fermentation of Pixian Doubantianzi

[0036] Blanch broad beans in boiling water for 3 minutes, drain for a while, and mix into flour according to the mass ratio of broad bean splits and flour at a ratio of 5:1, based on the total mass of broad bean splits and flour, and at the same time add Aspergillus oryzae spore powder with a mass fraction of 0.03‰ , placed in an environment at 30° C. and a relative humidity of 90% after being thoroughly mixed, and cultivated for 48 hours to obtain koji. Mix the koji and the brine with a mass volume fraction of 22% according to the mass ratio of 1:1, and at the same time, according to 10 5 The amount of each / g was inserted into the Zygomyces rouxii strain of the present invention, and fermented at 30°C for 30 days.

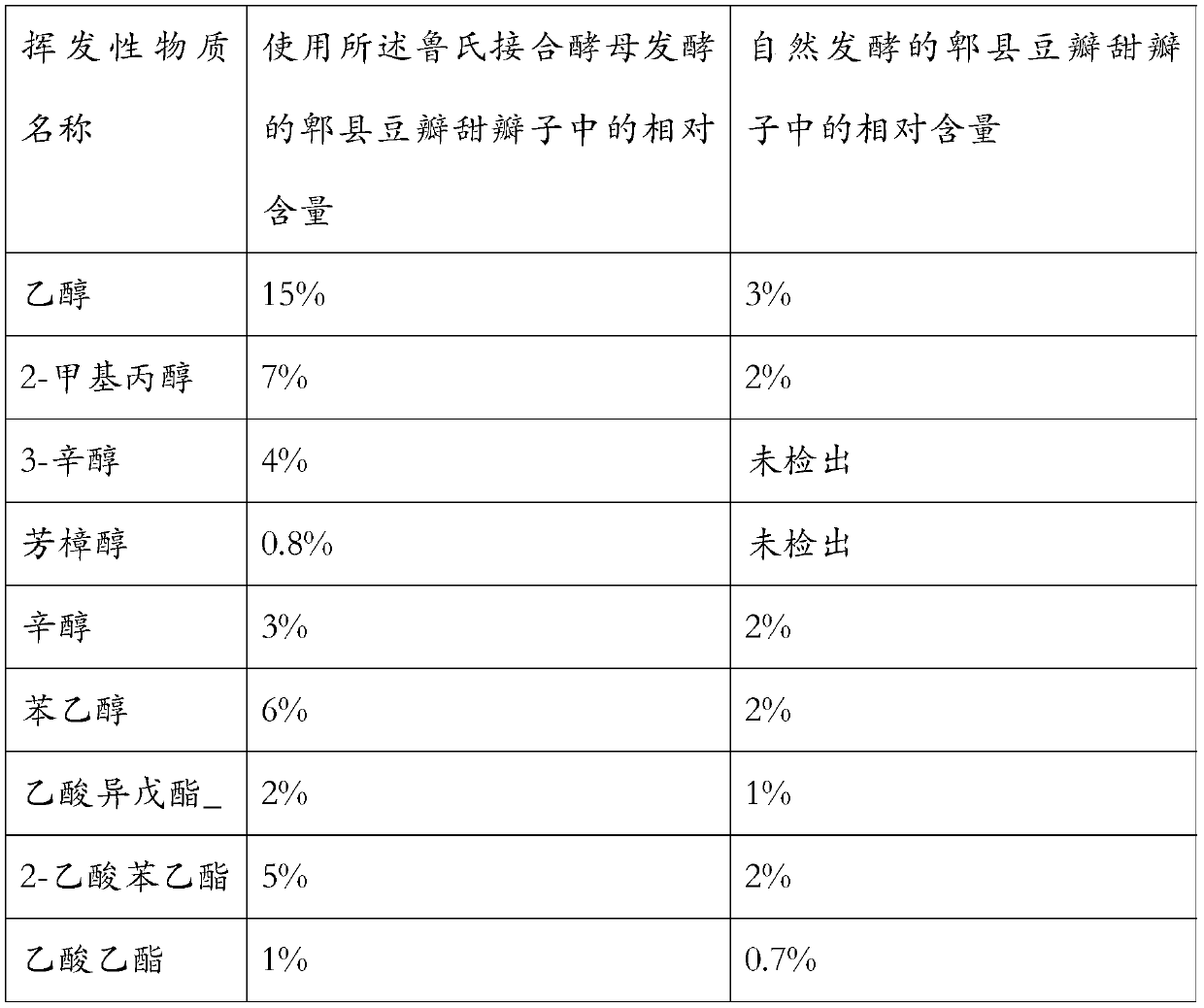

[0037] Solid-phase headspace microextraction was used to extract the main volatile components of the Pixian Doubanzizi fermented with Zygosaccharomyces...

Embodiment 2

[0043] Example 2: Application of Zygosaccharomyces rouxii Piniang J028 in fermentation of high-salt dilute soy sauce fermented grains

[0044] Steam the fully soaked soybeans, and after cooling, mix the cooked soybeans with flour at a mass ratio of 5:1, and add Aspergillus oryzae spore powder according to 0.03‰ of the total mass, and place the material at 35°C and a relative humidity of 90%. Cultured in an environment for 48 hours, the soy sauce koji was prepared, and the soy sauce koji was mixed with saline with a mass volume fraction of 25% at a mass ratio of 1:3, and at the same time, 10 5 Zygomyces rouckeri of the present invention was added in the amount of each / g, and fermented at 30° C. for 90 days. According to the mass ratio of soy sauce fermented grains and salt water at 1:1, add salt water with a mass volume fraction of 15%, soak for 48 hours, and extract the leachate to obtain soy sauce.

[0045] The main volatile components in the soy sauce fermented by Zygomyces...

Embodiment 3

[0052] Embodiment 3: the preparation of described Zygomyces rouckeri freeze-dried bacterial preparation

[0053] Zygomyces rouckeri described in the invention was formulated into a suspension with a dry matter mass fraction of 30%, and an equal volume of trehalose solution with a mass fraction of 20% was added at the same time, and frozen at -26°C after mixing (the cooling rate was 3°C / min ), sublimation temperature -40°C, pressure 10MPa. After drying, the material is divided into aluminum-plastic bags to obtain the freeze-dried microbial preparation of Zygomyces rouckeri. Colony counting was performed on the bacterial powder dilution, and the results showed that the number of live bacteria per gram of bacterial powder could reach 10 9 more than cfu.

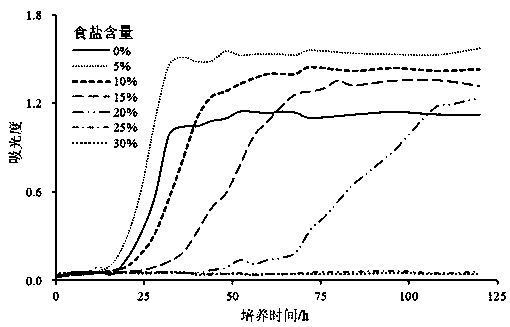

[0054] Experiment 1: Determination of Salt Tolerance of Zygomyces rouckeri

[0055] The screened yeast was divided into 10 4 Cells / mL were inoculated in YM liquid medium containing 0%, 5%, 10%, 15%, 20%, 25%, and 30% NaCl, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com