Modified waterborne epoxy resin curing agent and preparation method thereof

A technology of water-based epoxy resin and curing agent, applied in the direction of epoxy resin coating, coating, etc., can solve the problem of high viscosity, achieve the effect of mild reaction, good dispersion and emulsification performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a kind of preparation method of curing agent for modified water-based epoxy resin as described above, comprising the following steps:

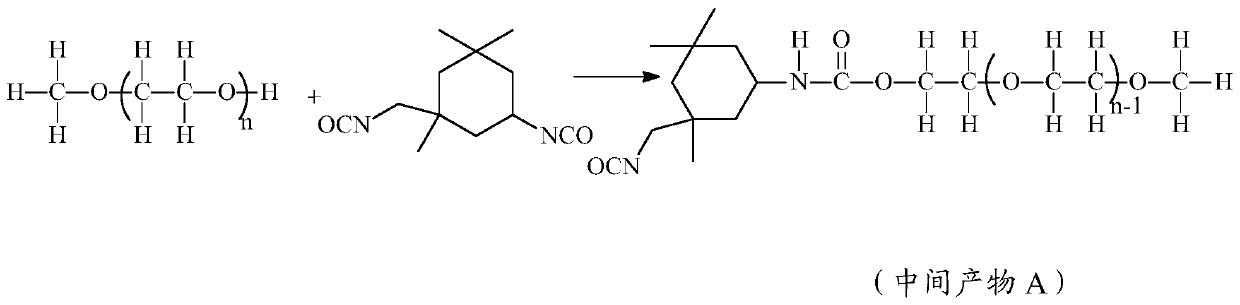

[0069] Step 1: reacting diisocyanate with polyethylene glycol monomethyl ether to obtain a reaction product I containing a urethane intermediate product A containing an isocyanate group at one end and a methoxy group at one end;

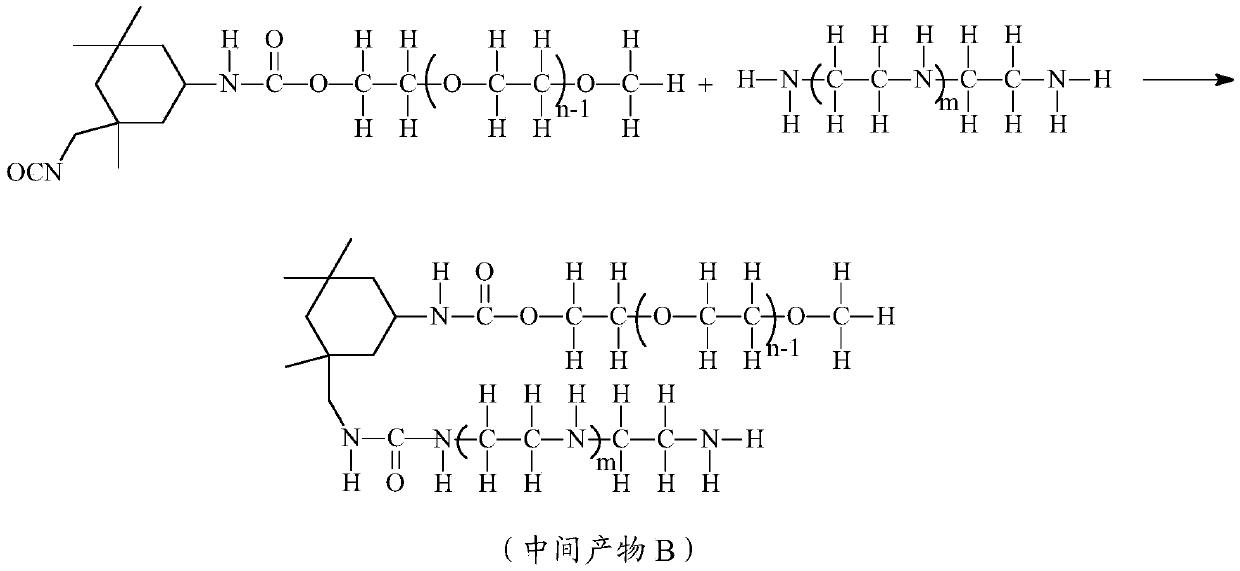

[0070] Step 2: The reaction product I obtained in step 1 contains enough remaining isocyanate groups to react with aliphatic polyamines to obtain a reaction product II containing a urea intermediate product B containing a methoxy group at one end and a primary amine group at one end;

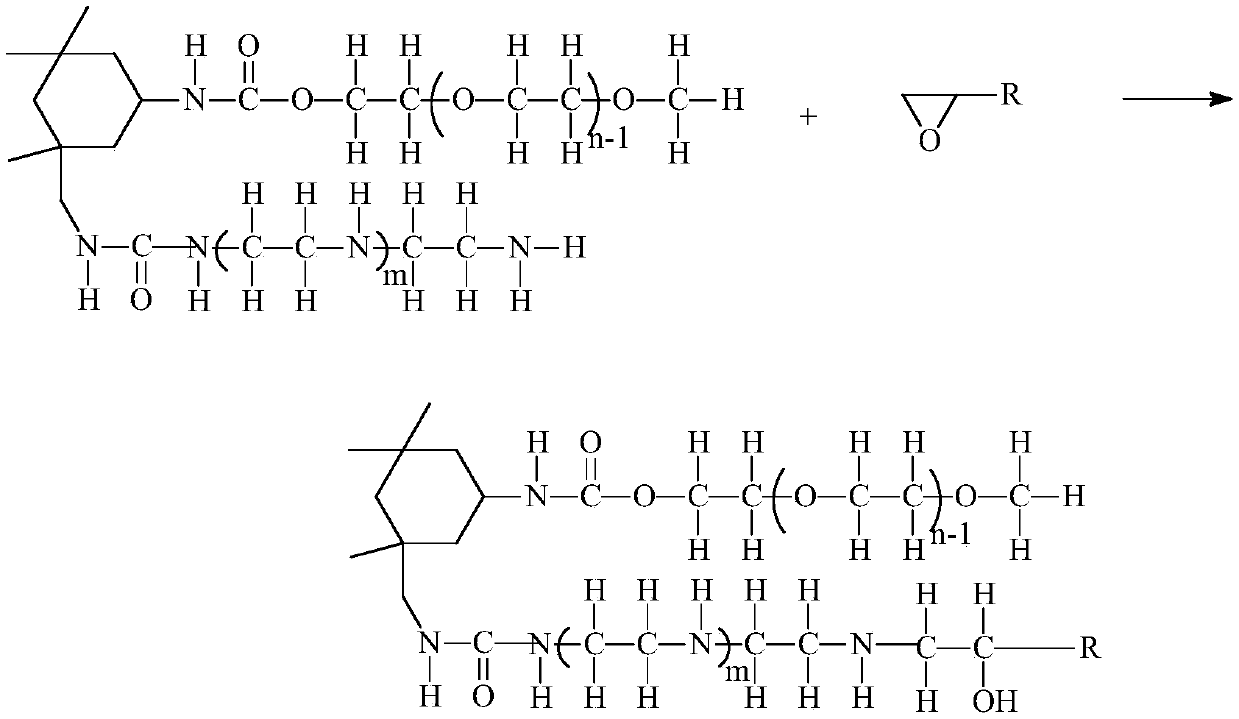

[0071] Step 3: The amount of primary amino groups contained in the reaction product II obtained in step 2 is sufficient to react with the monofunctional epoxy reactive diluent to obtain the curing agent for the modified water-based epoxy resin containing an alcohol amine product.

[0072] The ...

Embodiment 1

[0095] Step 1: Add 10g of isophorone diisocyanate (IPDI) into a 500mL four-neck flask with a thermometer and a condenser tube, raise the temperature to 30°C under nitrogen protection, and start the stirrer; A total of 33.78 g of polyethylene glycol monomethyl ether MPEG750, which had been dehydrated, was reacted for 1 hour; a reaction product I containing a urethane intermediate product A containing an isocyanate group at one end and a methoxyl group at one end was obtained;

[0096] Step 2: Add 8.51g of tetraethylenepentamine to the flask, slowly add the reaction product I obtained in step 1 to the flask dropwise, after the addition, slowly raise the temperature to 50°C and continue the reaction for 2h, and obtain Methoxyl group, reaction product II of urea intermediate product B containing primary amino group at one end;

[0097] Step 3: Add a monofunctional reactive diluent to the flask: 34.62g C12-14 alkyl glycidyl ether, slowly add the above-mentioned reaction product II ...

Embodiment 2

[0102] Step 1: Add 10g of isophorone diisocyanate (IPDI) into a 500mL four-necked flask with a thermometer and a condenser tube, raise the temperature to 40°C under nitrogen protection, and start the stirrer; A total of 54 g of polyethylene glycol monomethyl ether MPEG1200, which had been dehydrated, was reacted for 1 hour; a reaction product I containing a urethane intermediate product A containing an isocyanate group at one end and a methoxyl group at one end was obtained;

[0103] Step 2: Add 8.51g of tetraethylenepentamine to the flask, slowly add the reaction product I obtained in step 1 to the flask dropwise, after the dropwise addition, slowly raise the temperature to 70°C to continue the reaction for 2h, and obtain Methoxyl group, reaction product II of urea intermediate product B containing primary amino group at one end;

[0104] Step 3: Add monofunctional reactive diluent to the flask: 34.62g C12-14 alkyl glycidyl ether, slowly add the above-mentioned reaction produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com