Water-resistant polluted soil repair solidifying agent

A polluted soil, water-resistant technology, applied in the field of water-resistant polluted soil remediation and curing agent, can solve the problems of not widely used, unsatisfactory penetration depth of soil curing agent, etc., to improve anti-oxidation performance, prolong storage time, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] It is made from the following components in the proportion by weight: 5 parts of ordinary Portland cement, 40 parts of binder, 20 parts of reinforcing agent, 4 parts of early strength agent, 6 parts of waterproofing agent, 7 parts of filler, water reducing agent 3 parts of surfactant, 0.5 part of surfactant, 2 parts of dispersant, 0.02 part of retarder, 0.02 part of air-entraining agent, and 10 parts of blending emulsifier.

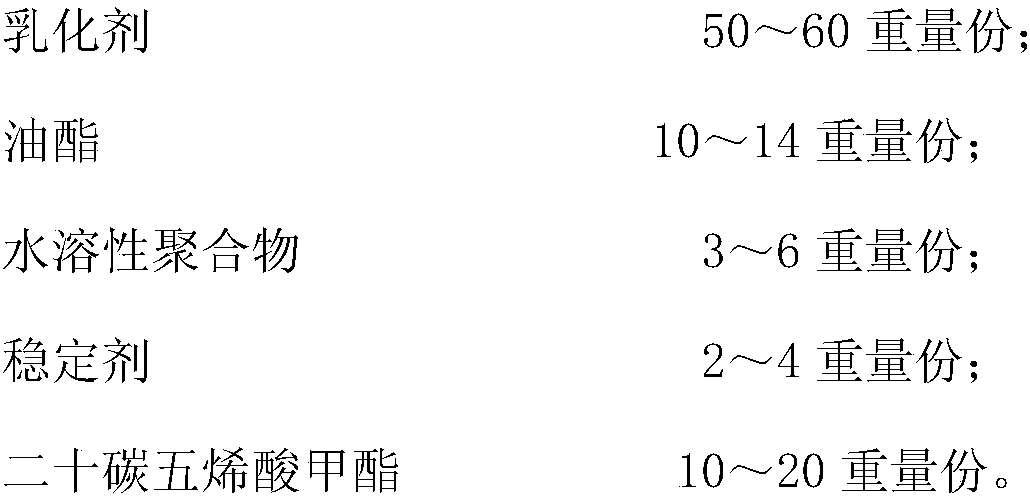

[0034] Wherein, the reconciling emulsifier includes the following components and proportions:

[0035]

[0036] The number average molecular weight of polyethylene oxide was 1200 g / mol.

Embodiment 2

[0038] It is made from the following components in the proportion by weight: 4 parts of ordinary Portland cement, 35 parts of binder, 15 parts of reinforcing agent, 2 parts of early strength agent, 4 parts of waterproofing agent, 5 parts of filler, water reducing agent 2 parts of surfactant, 0.3 part of surfactant, 1 part of dispersant, 0.01 part of retarder, 0.01 part of air-entraining agent, and 8 parts of blending emulsifier.

[0039] Wherein, the reconciling emulsifier includes the following components and proportions:

[0040]

[0041] The number average molecular weight of polyethylene oxide was 1300 g / mol.

Embodiment 3

[0043] It is made from the following components in the proportion by weight: 6 parts of ordinary Portland cement, 45 parts of binder, 25 parts of reinforcing agent, 6 parts of early strength agent, 9 parts of waterproofing agent, 9 parts of filler, water reducing agent 4 parts of surfactant, 0.7 part of surfactant, 3 parts of dispersant, 0.03 part of retarder, 0.03 part of air-entraining agent, and 11 parts of blending emulsifier.

[0044]

[0045]

[0046] The number average molecular weight of polyethylene oxide was 1400 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com