A kind of refined decolorization method of finasteride

A finasteride and dehydrogenation technology, which is applied in the refined decolorization field of finasteride, can solve problems such as unreachable color standards, difficult removal, DDQ residue, etc., to avoid solvent refining and reduce the use of organic solvents , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

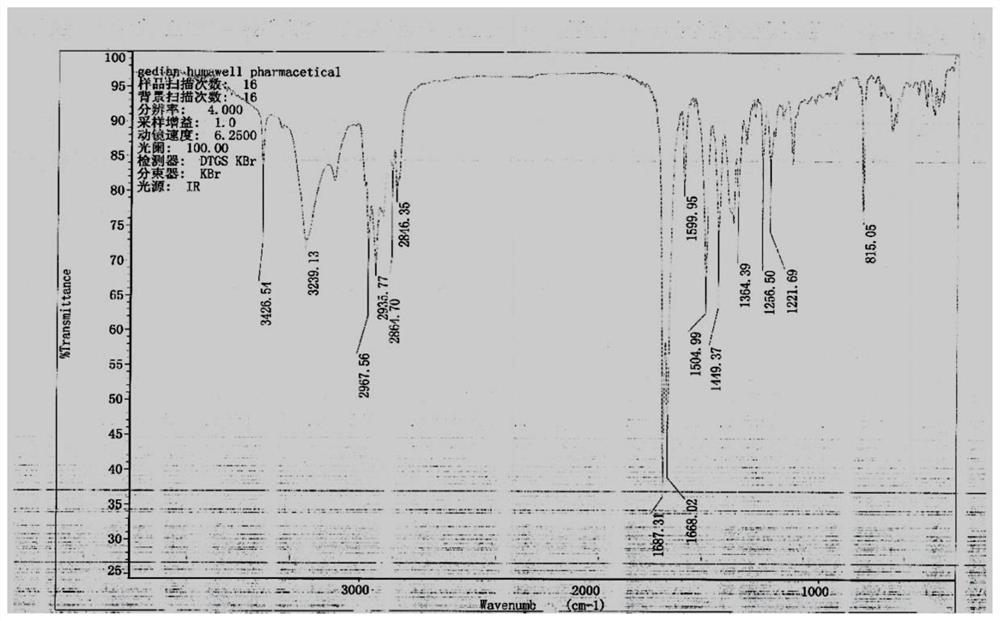

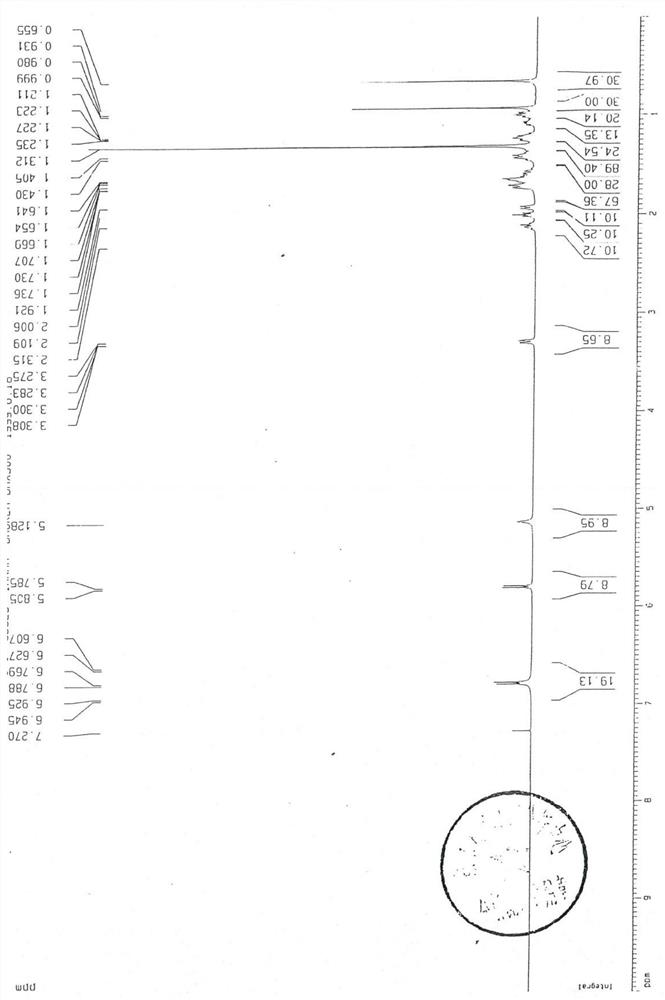

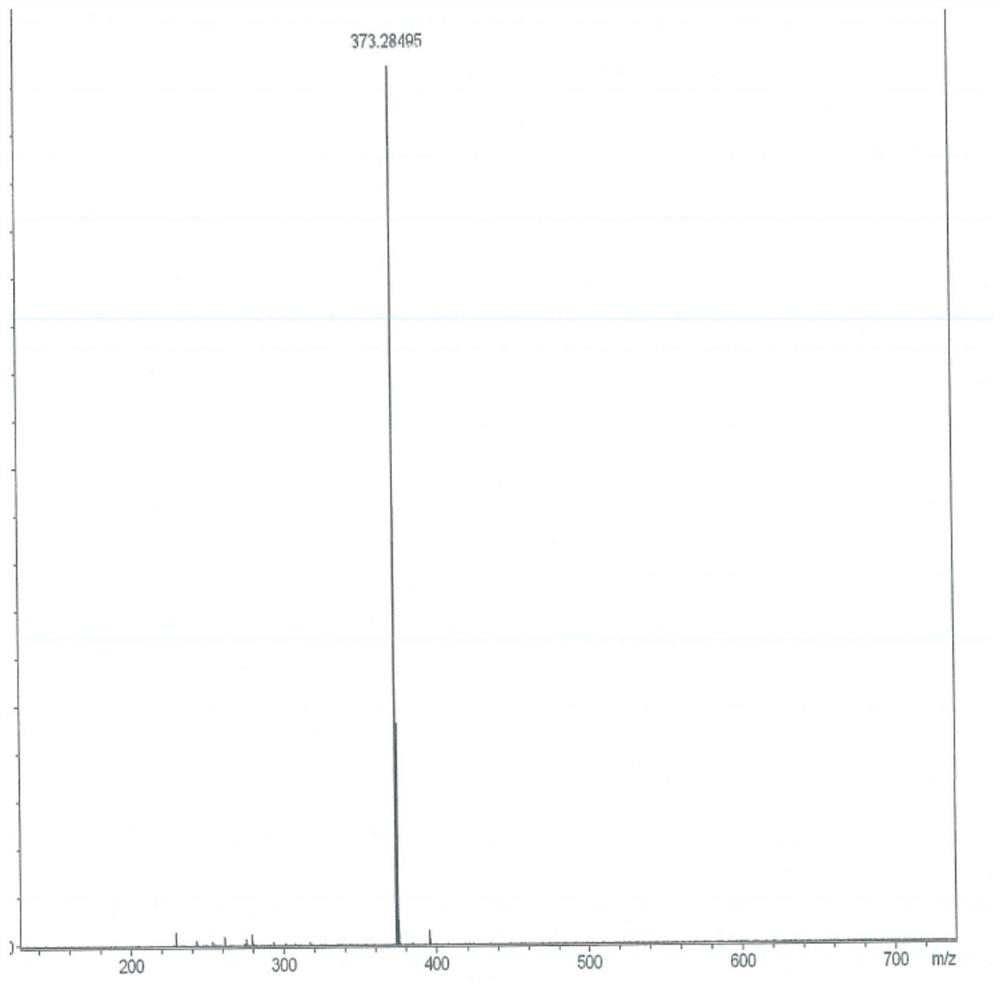

Embodiment 1

[0026] 10g N-tert-butyl-3-oxo-4-aza-5α-androster-17β-carboxamide (dihydroposcar) plus 200ml toluene, 8g DDQ, 35ml BSTFA after reflux reaction for 6h to obtain a dehydrogenation reaction solution , after cooling down to room temperature, add 50g of 5% sodium bisulfite solution, raise the temperature to about 45°C and stir vigorously for 0.5h, at this time, a large amount of solids precipitate out of the reaction solution, filter, wash the solids with a small amount of toluene, combine the toluene liquids, and add Mix salt solution (sodium borohydride 0.5g + sodium thiosulfate 4g + 30g water), heat up to 40°C and stir vigorously for 0.5h, let stand to separate layers, wash the toluene layer twice with 5% aqueous sodium carbonate solution, and wash with drinking water 1 time, concentrated to dryness under negative pressure, then added about 10ml of isopropyl acetate to it and heated to reflux for beating for 0.5h, cooled and filtered to obtain 9.16g of white finasteride. The quali...

Embodiment 2

[0028] 10g N-tert-butyl-3-oxo-4-aza-5α-androster-17β-carboxamide (dihydroposcar) plus 200ml toluene, 8g DDQ, 35ml BSTFA after reflux reaction for 6h to obtain a dehydrogenation reaction solution , after cooling down to room temperature, add 50g of 5% sodium bisulfite solution, raise the temperature to about 45°C and stir vigorously for 0.5h, at this time, a large amount of solids precipitate out of the reaction solution, filter, wash the solids with a small amount of toluene, combine the toluene liquids, and add Mix salt solution (sodium borohydride 0.4g + sodium thiosulfate 3g + 40g water), heat up to 35°C and stir vigorously for 1h, let stand to separate layers, wash the toluene layer with 5% aqueous sodium carbonate solution twice, and wash with drinking water once Once, concentrate to dryness under negative pressure, then add about 10ml of isopropyl acetate to it and heat up to reflux for beating for 0.5h, filter after cooling, and obtain 9.24g of white finasteride. The qua...

Embodiment 3

[0030] 10g N-tert-butyl-3-oxo-4-aza-5α-androster-17β-carboxamide (dihydroposcar) plus 200ml toluene, 8g DDQ, 35ml BSTFA after reflux reaction for 6h to obtain a dehydrogenation reaction solution , after cooling down to room temperature, add 50g of 5% sodium bisulfite solution, raise the temperature to about 50°C and stir vigorously for 0.5h, at this time, a large amount of solids precipitate out of the reaction solution, filter, wash the solids with a small amount of toluene, combine the toluene liquids, and add Mix salt solution (sodium borohydride 0.6g + sodium metabisulfite 4g + 30g water), heat up to 30°C and stir vigorously for 1 hour, let stand to separate layers, wash the toluene layer twice with 5% aqueous sodium carbonate solution, and wash it once with drinking water. Concentrate to dryness under negative pressure, then add about 10ml of isopropyl acetate to it, heat up to reflux for beating for 0.5h, filter after cooling, and obtain 9.28g of white finasteride. The qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com