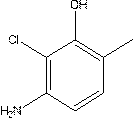

Preparation and purification method of 6-chloro-5-amino o-cresol

A technology of amino-o-cresol and purification method, which is applied in the field of preparation and purification of 6-chloro-5-amino-o-cresol, can solve the problem that the purification method is not mentioned in public documents, and achieves good quality and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

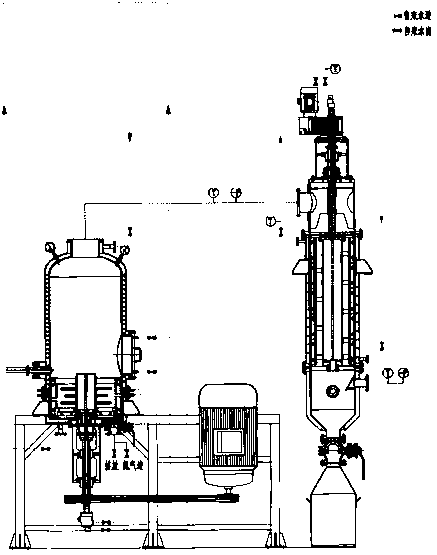

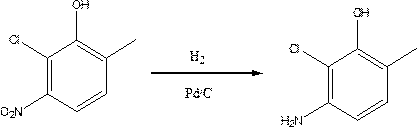

[0033] Put 500 kg of methanol, 100 kg of 6-chloro-5-nitro-o-cresol and 1 kg of 5% palladium carbon into a 1000-liter high-pressure hydrogenation kettle, replace the air in the kettle with nitrogen three times, and then replace the nitrogen with hydrogen. Pass hydrogen to react, control the internal temperature at 60°C, and the pressure in the kettle at 0.2MPa.

[0034] Keep warm for 2.5h to stop the reaction. Filter under nitrogen pressure to remove the catalyst. The resulting filtrate enters the solvent recovery tank. Open the steam and recover the solvent methanol.

[0035] After recovery, about 78.4 kg of crude product of 6-chloro-5-nitro-o-cresol was obtained by drying.

[0036] In a 100-liter sublimation kettle, put 70 kg of the above-mentioned crude product of 6-chloro-5-amino-o-cresol, control the internal temperature at 100°C, and feed nitrogen gas with a nitrogen flow rate of 45 L / min. The sublimation material is smashed, and the sublimation time is about 10 hours...

Embodiment 2

[0039] Put 600 kg of methanol, 100 kg of 6-chloro-5-nitro-o-cresol and 5 kg of 5% palladium carbon into a 1000-liter high-pressure hydrogenation kettle, replace the air in the kettle with nitrogen three times, and then replace the nitrogen with hydrogen. Pass hydrogen to react, control the internal temperature at 80°C, and the pressure in the kettle is 0.4MPa.

[0040] Keep warm for 5h, stop the reaction. Filter under nitrogen pressure to remove the catalyst. The resulting filtrate enters the solvent recovery tank. Open the steam and recover the solvent methanol.

[0041] After recovery, about 75.9 kg of crude product of 6-chloro-5-nitro-o-cresol was obtained by drying.

[0042] In a 100-liter sublimation kettle, put 70 kg of the above-mentioned 6-chloro-5-amino-o-cresol crude product, control the internal temperature at 135°C, feed nitrogen gas, and the nitrogen flow rate is 65L / min. The sublimates are smashed, and the sublimation time is about 2 hours until the product i...

Embodiment 3

[0045] Put 550 kg of ethanol, 100 kg of 6-chloro-5-nitro-o-cresol and 1 kg of 5% palladium carbon into a 1000-liter high-pressure hydrogenation kettle, replace the air in the kettle with nitrogen three times, and then replace the nitrogen with hydrogen. Pass hydrogen to react, control the internal temperature at 70°C, and the pressure in the kettle at 0.2MPa.

[0046] Keep warm for 5h, stop the reaction. Filter under nitrogen pressure to remove the catalyst. The resulting filtrate enters the solvent recovery tank. Open the steam and recover the solvent methanol.

[0047] After recovery, about 77.5 kg of crude product of 6-chloro-5-nitro-o-cresol was obtained by drying.

[0048] In a 100-liter sublimation kettle, put 70 kg of the above-mentioned 6-chloro-5-amino-o-cresol crude product into it, control the internal temperature at 110°C, and feed nitrogen gas with a nitrogen flow rate of 50 L / min. The sublimation is broken, and the sublimation time is about 5.5 hours until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com