A flame-retardant and puncture-resistant high-barrier sheet and its preparation method

A high-barrier, puncture-resistant technology, applied in the field of building materials, can solve problems such as the need to improve the barrier performance, the waterproof effect cannot be guaranteed, and the flexibility of the sheet is reduced, and achieves the effect of saving raw materials, saving materials, and high filling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

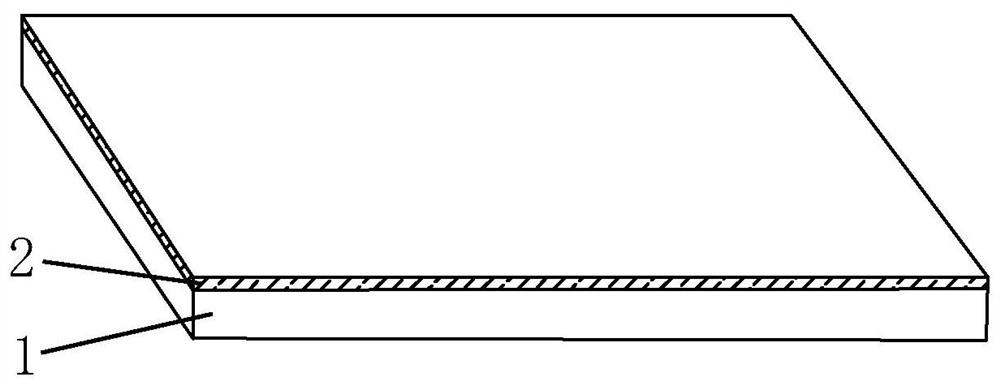

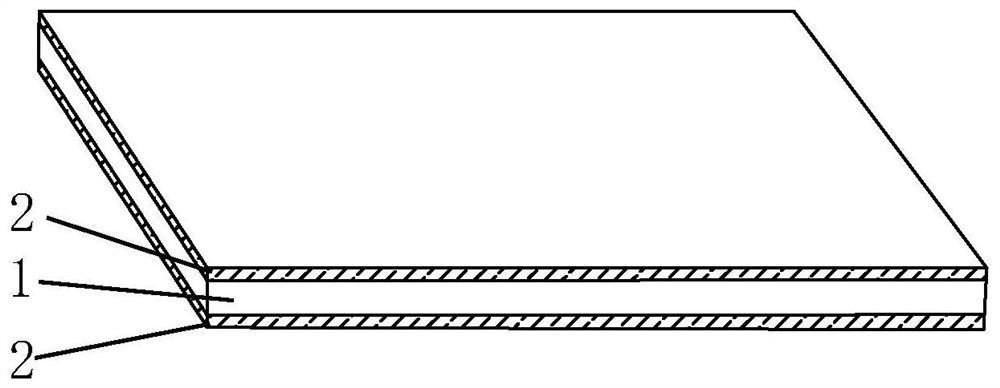

[0035] The preparation method of this flame-retardant puncture-resistant high-barrier sheet, the steps are as follows:

[0036] Step 1: Grind MPE resin, HDPE, halogen flame retardant masterbatch, barrier material and elastomer respectively for 10-15 minutes, mix and dry; At a temperature of 100°C, mix for 100min-140min and rotate at a speed of 800-1200r / min to obtain a blend;

[0037] Step 2: Add the blend to a high-speed internal mixer for mastication and then knead. The kneading temperature is 120°C and the kneading time is 60 minutes. mm of PE substrate layer 1;

[0038] Step 3: Weigh the raw materials according to the above components, mix MPE resin, halogen flame retardant masterbatch, barrier material and maleic anhydride modified PE resin evenly, and then add them to the high-speed mixer. Next, mix for 100min-140min, and the rotating speed is 800-1200r / min to obtain a blend;

[0039] The fourth step: Melt and plasticize the above blend through a twin-screw extruder, an...

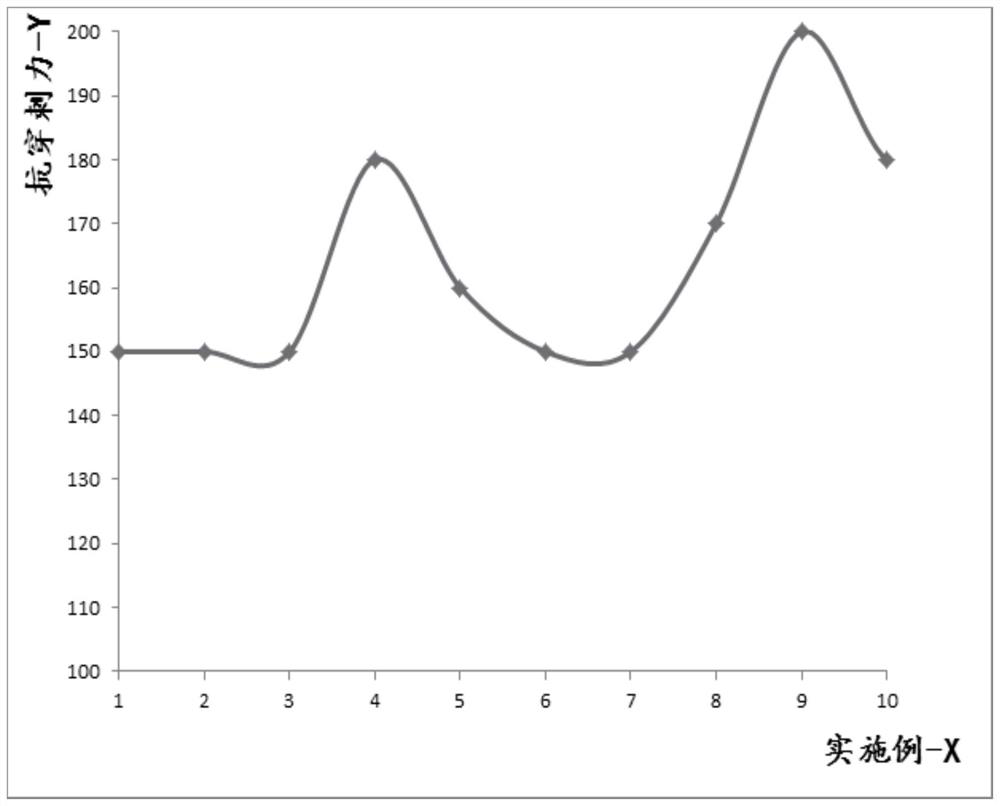

Embodiment 9

[0071] Example 9 is the best option of the present invention, with the most excellent performance. The sheet prepared by the present invention has good thermal dimensional stability and excellent high barrier and water impermeability. The bottom is impermeable, the flame retardancy is at least above B1, and can reach Class A, flame retardant or even non-combustible, the puncture resistance is higher than the industry standard, the puncture resistance is 150N and above, and the highest can reach 200N. It has excellent low-temperature flexibility and does not produce any cracks at -40°C. It has good welding joint strength and cohesion, up to 8N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com