An organic acid system and preparation method for acidizing carbonate reservoir

A carbonate reservoir and organic acid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that the effect of acidizing stimulation cannot reach the expected purpose, the length of acid-etched fractures cannot be increased, and oil and gas production is affected out of question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

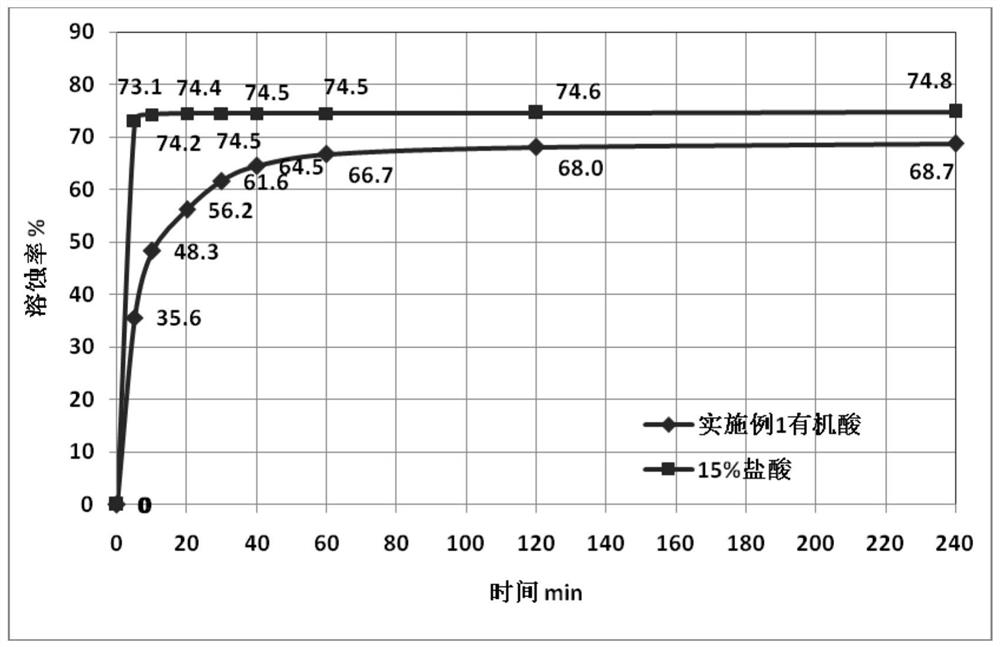

Embodiment 1

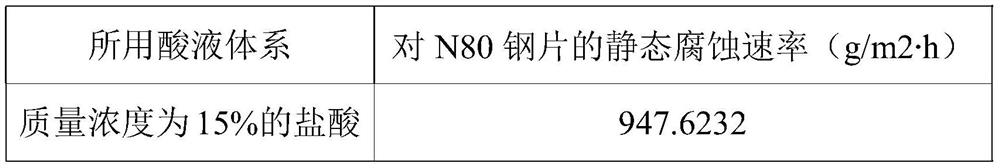

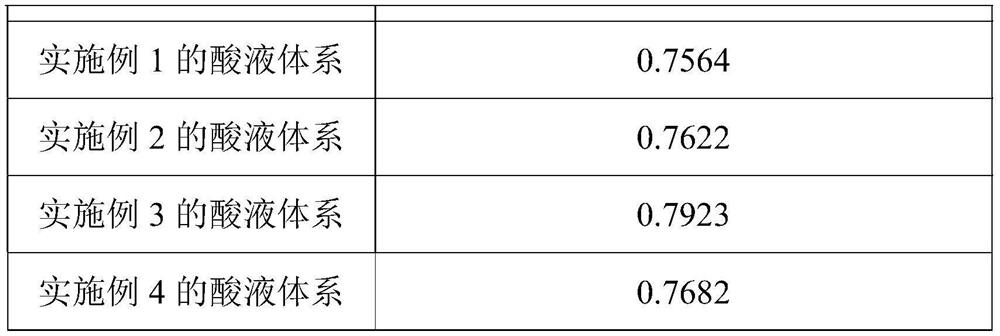

[0024] First set the quality of the organic acid system to be configured, prepare organic acid liquid, the mass fraction of organic acid liquid in the organic acid system is 45%, adopt formic acid, acetic acid, benzoic acid, oxalic acid, succinic acid and propionic acid to form a mixed organic acid The acid solution has a mass ratio of 3:2:1:0.5:2:1.5.

[0025] EDTA is disodium EDTA, with a mass fraction of 0.2%.

[0026] The other components are 1% of corrosion inhibitor, 0.03% of retarding additive, 0.03% of iron ion stabilizer and 0.1% of drainage aid.

[0027] The iron ion stabilizer uses citric acid solution with a mass fraction of 40%, the drainage aid uses CF-5B and 1831 to form a mixed solution with a mass ratio of 1:1, and the corrosion inhibitor consists of imidazoline corrosion inhibitors and quaternary ammonium salts. The corrosion agents are mixed according to the mass ratio of 0.5:1 to form a mixed corrosion inhibitor.

[0028] Hydrophobic modified nano-SiO was...

Embodiment 2

[0031] First, set the quality of the organic acid system to be configured, prepare an organic acid solution, the mass fraction of the organic acid solution is 50%, use formic acid, acetic acid, benzoic acid, oxalic acid, succinic acid and propionic acid to form a mixed organic acid solution, the mass ratio It is 3:2:1:0.5:2:1.5.

[0032] EDTA is selected from disodium EDTA, and the mass fraction is 0.5%.

[0033] The other components are 0.3% of corrosion inhibitor, 0.08% of retarding additive, 0.08% of iron ion stabilizer and 0.5% of drainage aid.

[0034] The iron ion stabilizer uses citric acid solution with a mass fraction of 40%, the drainage aid uses CF-5B and 1831 to form a mixed solution with a mass ratio of 5:1, and the corrosion inhibitor consists of organic phosphonate corrosion inhibitors and thiourea series The corrosion inhibitors are mixed according to the mass ratio of 2:1 to form a mixed corrosion inhibitor.

[0035] Hydrophobic modified nano-SiO was selecte...

Embodiment 3

[0038] First, the quality of the organic acid system to be configured is set, and the organic acid solution is prepared. The mass fraction of the organic acid solution is 55%. Formic acid, acetic acid, benzoic acid, oxalic acid, succinic acid and propionic acid are used to form a mixed organic acid solution. The mass ratio It is 3:2:1:0.5:2:1.5.

[0039] EDTA is selected from disodium EDTA, and the mass fraction is 0.7%.

[0040] The other components are 0.7% of corrosion inhibitor, 1% of retarding additive, 1% of iron ion stabilizer and 0.7% of drainage aid.

[0041] The iron ion stabilizer uses citric acid solution with a mass fraction of 40%, the drainage aid uses CF-5B and 1831 to form a mixed solution with a mass ratio of 2:1, and the corrosion inhibitor consists of imidazoline corrosion inhibitors and acetylenic alcohol inhibitors. The corrosion inhibitor is mixed according to the mass ratio of 1:1 to form a mixed corrosion inhibitor.

[0042] Hydrophobic modified nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com